TO THE GLEANING

EQI'IPMENT OWNER

Since 1970,

Wayne

has

supplied

the hot

water

pressure

washer cleaning

equipment

industry with

oil burners. You

are obtaining

a

quality

burner

unsurpassed in

engineering design and

product

development.

lt will

provide you

with

many

years

of efficient

trouble-free operation,

if

properly

installed and

serviced. Please read

this manual carefully.

Wayne

warrants

its

burners specifically

to those who have

purchased

it for resale, including

your

dealer. lf,

in

any

case,

you

have

a

problem

with

your

burner,

or

its installation,

you

should contact

your

dealer

or the

cleaning

equip-

ment manufacturer

for assistance.

FUEL

UNITS

AND OIt LTNES

The

model

MSR-DC

oil burner

is

provided

with

a single

stage 3450

RPM fuel unit

with

by-pass

plug

removed for

a

single

pipe

installation; the by-pass

plug

for two

pipe (inlet

and

return)

is

provided

in the

plastic

bag attached to the

fuel unit.

The

installation

of fuel

filters

are

recommended. Check

supply

tank for sludge

accumulation

and

leakage.

Use only

flare fittings

on

all

piping

and

connections since

compression

fittings

will eventually

leak. With

the

system running,

the

vacuum

should

not exceed 12" mercury

for

single

stage units. For

ease of servicing,

installa

shut off

valve

near

burner.

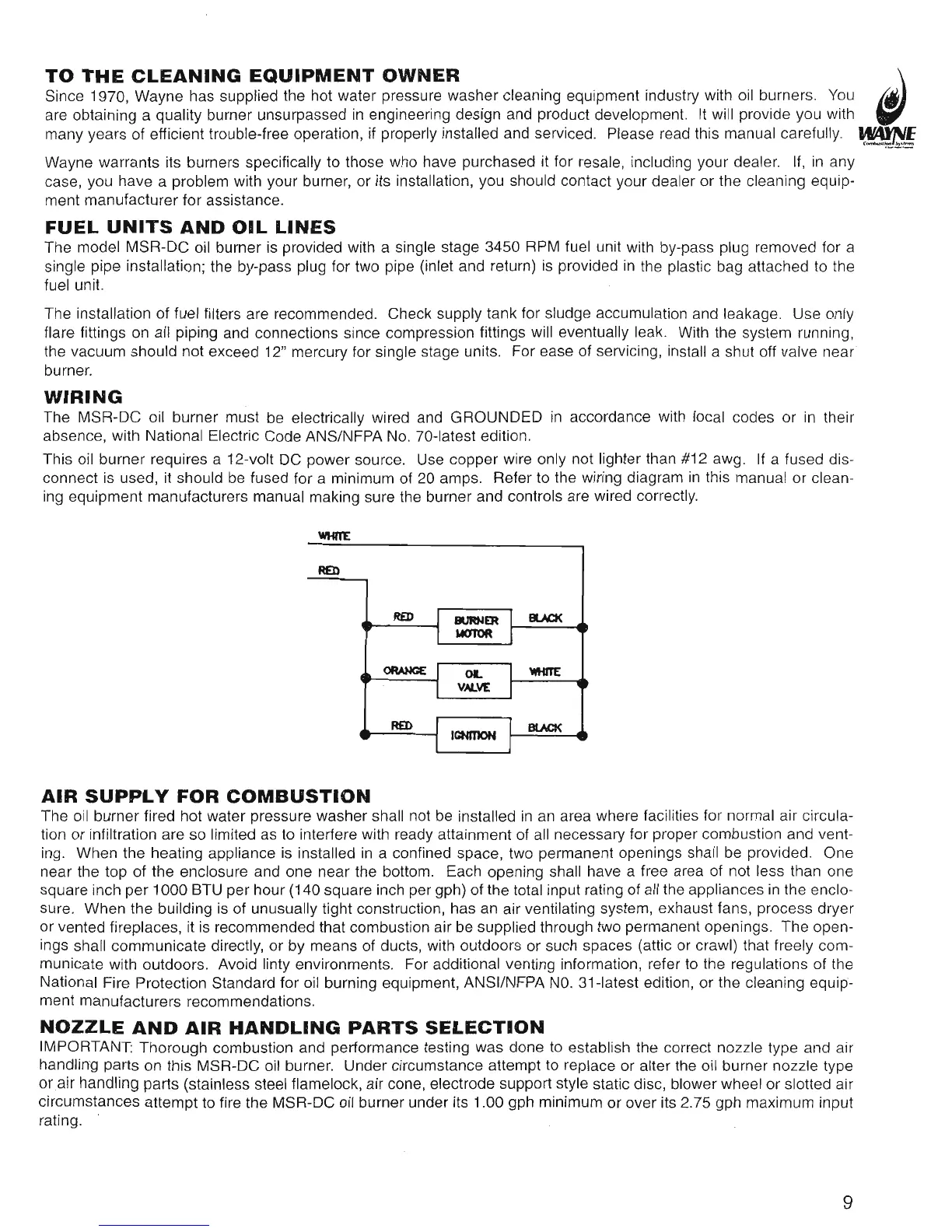

WIRING

The

MSR-DC

oil burner

must

be

electrically

wired and GROUNDED

in

accordance

with local codes or in their

absence,

with National

Electric Code

ANS/NFPA No. 7O-latest

edition.

This

oil burner

requires

a 12-volt

DC

power

source. Use

copper

wire only not

lighter than #12 awg.

lf

a f used dis-

connect

is

used,

it

should be

fused for a minimum of

20 amps.

Refer to the wiring

diagram in this manual or clean-

ing

equipment

manufacturers manual making sure

the

burner

and

controls

are wired correctly.

AIR SUPPLY FOR

COMBUSTION

The

oil burner

fired hot

water

pressure

washer shall

not

be

installed in an area

where facilities

for

normal air circula-

tion or

infiltration are

so limited as

to interfere with ready attainment

of all necessary

for

proper

combustion and vent-

ing. When the heating

appliance

is

installed in

a confined

space, two

permanent

openings shall be

provided.

One

near the top

of

the

enclosure and one near the

bottom.

Each

opening

shall

have a free area

of not less than

one

square

inch

per

1000

BTU

per

hour

(140

square inch

per

gph)

of

the

total input rating

of all

the

appliances in the enclo-

sure. When the building

is

of unusually tight

construction,

has an air ventilating

system,

exhaust fans,

process

dryer

or

vented

fireplaces, it is recommended

that

combustion air

be supplied

through

two

permanent

openings. The

open-

ings

shall

communicate

directly, or

by means

of ducts,

with outdoors

or such

spaces

(attic

or

crawl)

that freely

com-

municate with

outdoors.

Avoid linty environments. For additional

venting information,

refer to the

regulations of

the

National

Fire Protection

Standard

for oil

burning

equipment,

ANSI/NFPA

N0. 31-latest

edition,

or

the

cleaning equip-

ment manufacturers

recommendations.

NOZZLE

AND

AIB

HANDLING

PARTS

SE!.ECTION

IMPORTANT

Thorough

combustion

and

performance

testing

was

done to

establish the correct nozzle type and air

handling

parts

on

this MSR-DC oil burner. Under circumstance

attempt

to replace or alter

the

oil burner

nozzle

type

or

air handling

parts

(stainless

steel

flamelock, air cone,

electrode

support style

static disc, blower

wheel

or slotted air

circumstances attempt

to fire

the MSR-DC

oil burner

under its 1.00

gph

minimum

or

over

its 2.75

gph

maximum input

rating.

I

UI{IE

Loading...

Loading...