H. IGNITION SYSTEMS

Page 30 Ignition SystemsJB Manual

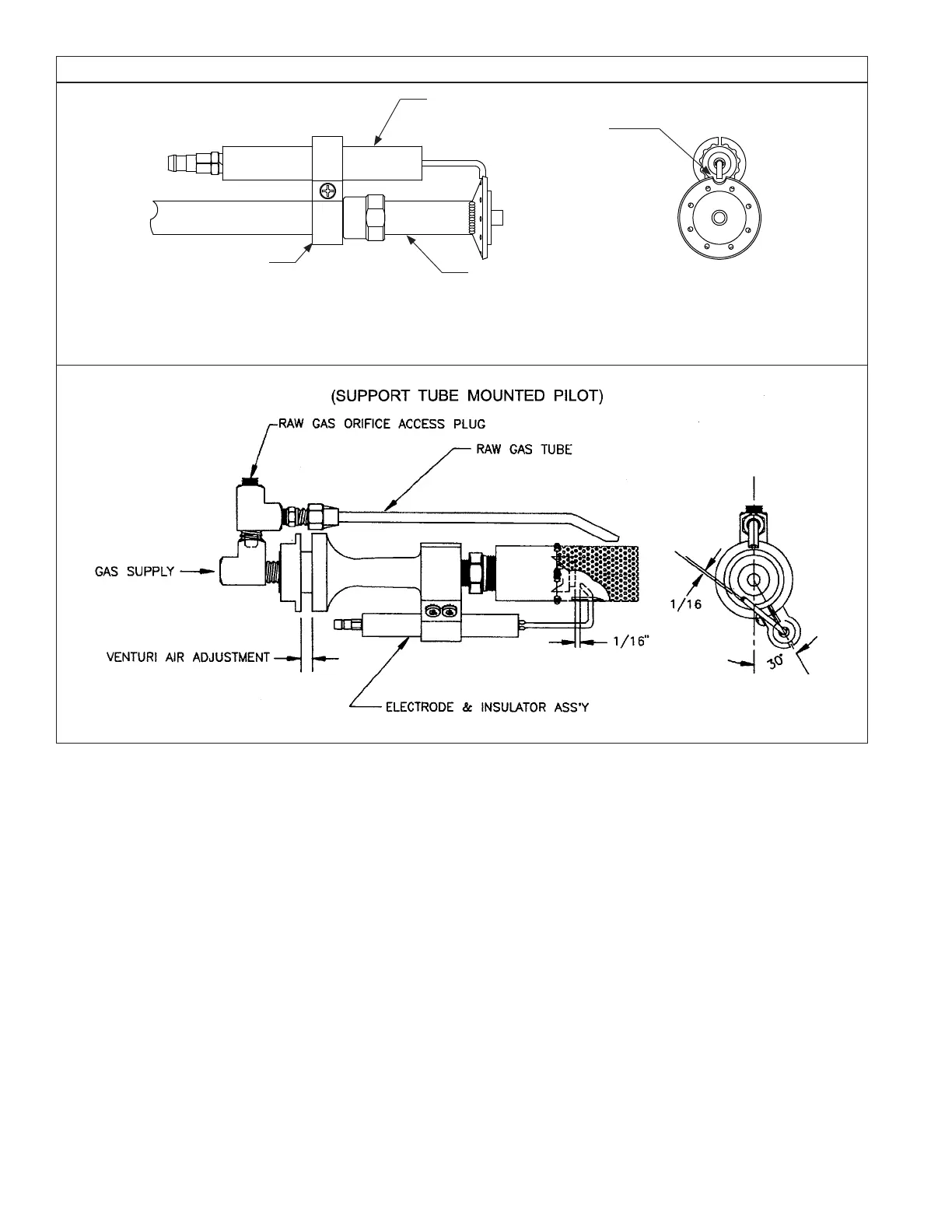

1. Gas Pilot Assembly

A crucial part of reliable burner operation is a dependable

pilot, which must be properly adjusted and kept clean. A gas

pilot is standard for all models except JB1 through JB2-20

straight oil pressure atomizing burners which have direct

spark ignition as standard. The following illustrations show

the typical confi guration and nominal adjustment parame-

ters of each pilot.

Figure H-1 showns the JB1 & JB2 gas pilot. Figure H-2

shows the JB3 gas pilot. Figure H-3 shows how the pilots

are positioned in the burner drawer.

Pilot gas pressure should be measured at the 1/8” port locat-

ed on the downstream side of the last pilot solenoid valve.

2. Oil Nozzle Positiion, Direct Spark Oil.

Figures H-5 and H-6 show the position of direct spark igni-

tion and nozzle positions. These are initial settings and will

be adjusted at start-up.

3. Air Damper Position

On a straight gas burner, the air damper should be open

about 1/4” at low fi re and close to full open at high fi re. In

Figure H-2 JB3 PILOT ASSEMBLY

Natural Gas Pressure;

4 - 6” wc

LP Gas Pressure;

1.5 - 2.5” wc

some applications, the pilot requires an orifi ce in the pilot

gas supply line. With the exception of the JB3, this ori-

fi ce is located external of the blower housing.

The pilot to diffuser dimension is the distance of the face

of the pilot to the outer diameter of the diffuser.

For an oil or combination burner, the air damper should

be open about 3/8” at low fi re and close to full open at

high fi re.

4. Gas Modualting Control Valve Position

The gas valve should be open about 10% at low fi re and

stroked to abput 60% open at high fi re.

5. Oil Modulatining Control Valve Position.

For pressure atomizing, the low fi re position should be

adjusted to get the correct low fi re presure, as stated

on the rating label. Typically, this would be 100 psi for

simplex systems and 65 psi for return fl ow nozzles. The

high fi re position should be about 45

o

to 60

o

travel from

low fi re.

For air atomizing, the low fi re should be on about #2 po-

sition and the high fi re should be about the #8 position.

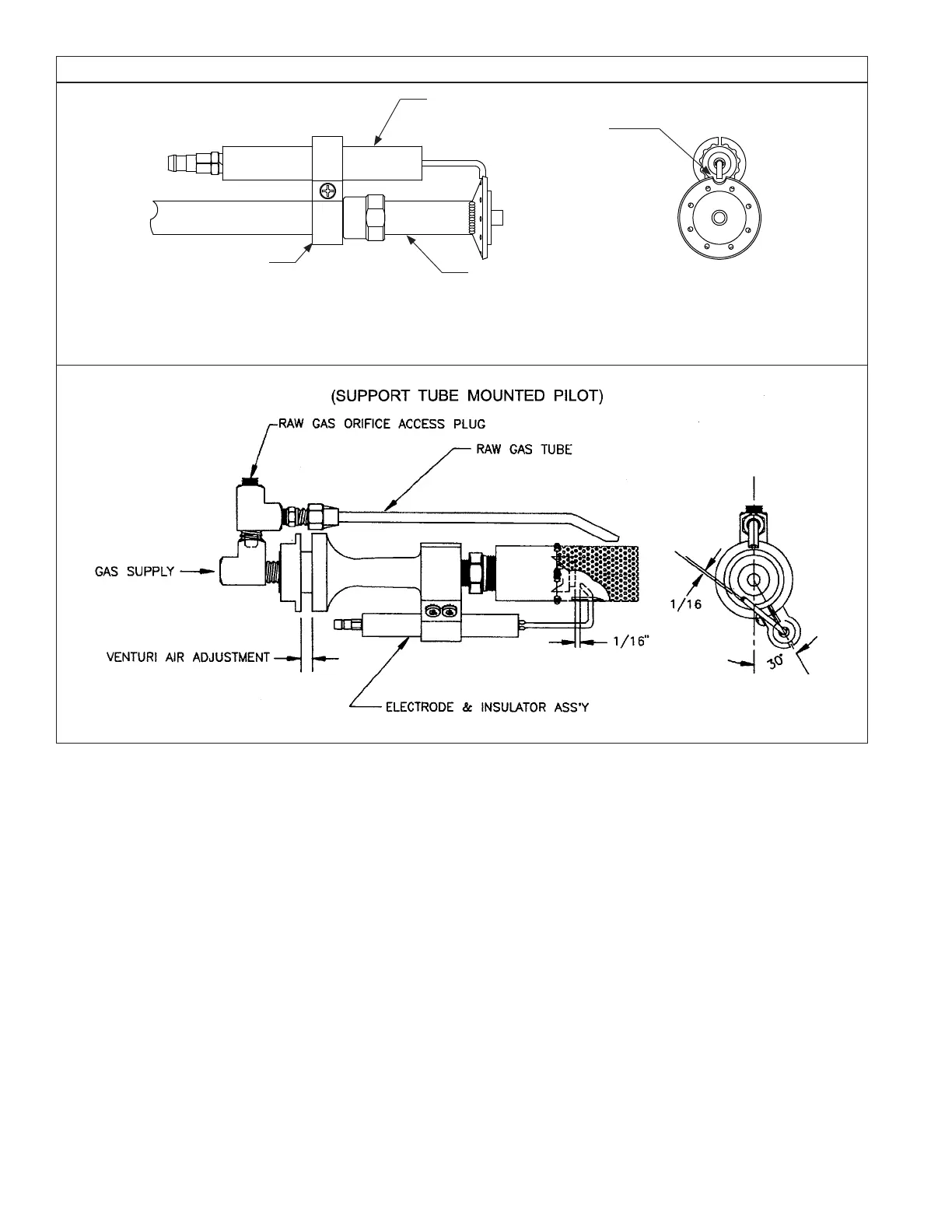

Electrode

Pilot

Electrode Clamp

Figure H-1

JB1 & JB2 Gas Pilot

Spark

Gap = 1/16”

Note: Required 2 1/2” - 3” wc

pressure for natural gas ans 1/2”

- 2” for LP, as measured at the

last solenoid in the pilot train.

Loading...

Loading...