- 12 -

Maintenance

Keep the maintenance of the machine tool during the operation to guarantee the accuracy and

service life of the machine.

1. In order to retain the machine’s precision and functionality, it is essential to treat it with care, keep

it clean and grease and lubricate it regularly. Only through good care, you can be sure that the

working quality of the machine will remain constant. Disconnect the machine plug from the

mains supply whenever you carry out cleaning, maintenance or repair work!

2. Lubrication all slideways lightly before every use. The leadscrew must also be lightly lubricated

with lithium base grease.

3. During the operation, the chips what falls onto the sliding surface should be cleaned timely, and

the inspection should be often made to prevent chips falling into sliding ways. Asphalt felt should

be cleaned at certain time. Do not remove the chips with your bare hands. There is a risk of

cuts due to sharp-edged chips.

4. After the operation every day, eliminate all the chips and clean different part of the machine and

apply machine oil to prevent rusting.

5. In order to maintain the machining accuracy, take care of the arbor, drawbar, the surface of the

worktable and the guide way and avoid mechanical damage and the wear due to improper guide.

6. If the damage is found, the maintenance should be done immediately.

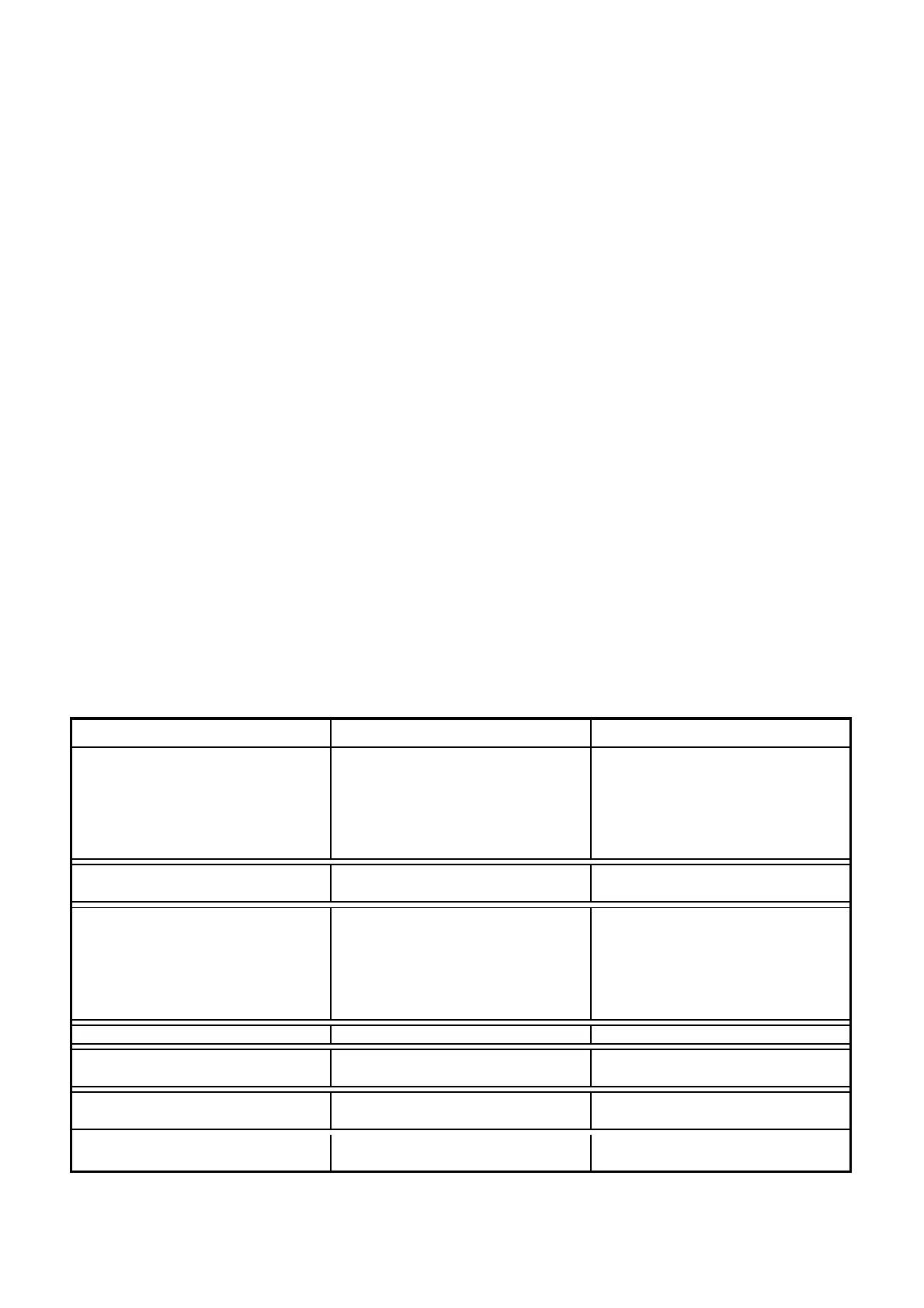

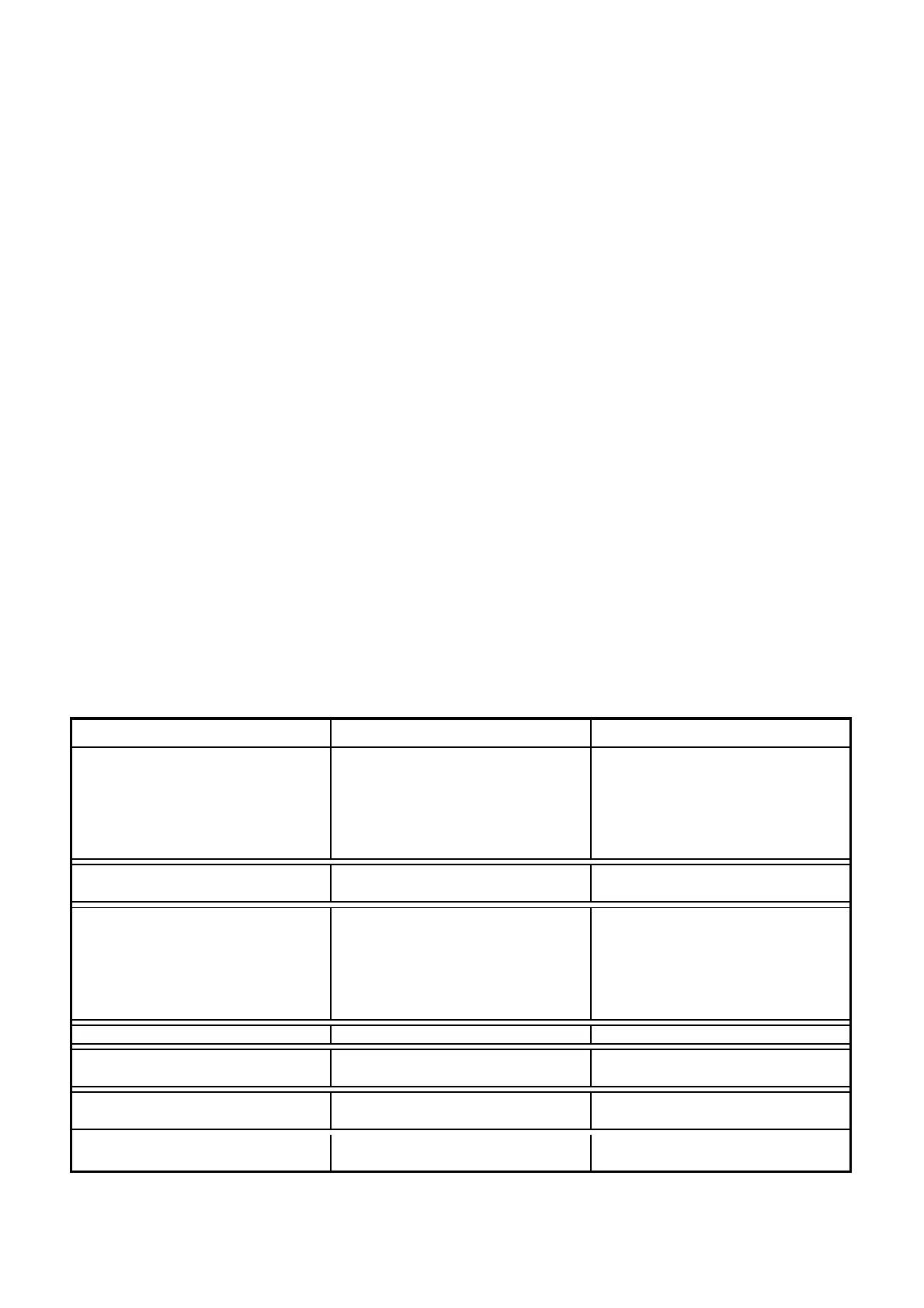

Trouble Solution

Problem Possible Cause Solution

Gibs too loose on table, column Readjust gibs

Unused feeds not locked Lock all axes but the one moving

Mill head not locked Lock mill head

Quill too loose Tighten quill lock

Tool not on center Center tool

Improper tool shape, tool dull reshape, sharpen, or replace tool

Quill moving Lock quill

Setup wrong Make sure setup is parallel to table

Bit dull Use sharp bits

Bit not mounted correctly in chuck Remount tool

Chuck loose in spindle Remount chuck on arbo

Drawbar not secured Tighten drawba

Bearing loosen or worn Tighten or replace bearings

Cutting too fast Reduce speed

Bit turns erraticall

or stops

Bit fed into work too fast Reduce feed rate

Chuck sticking

pply lubricant

Debris in chuck Clean chuck

Chuck loose on arbo

Clean arbor and remount

Drawbar not tight Clean spindle and replace drawba

Machine unplugged Plug in machine

Loose electrical connections Tighten wiring connections

Chuck wobbles

Turn on machine and nothing happe

Depth of cut is not consistent

Too chatters

Hole is off center or bit wanders

Chuck is difficult to tighten or loosen

Loading...

Loading...