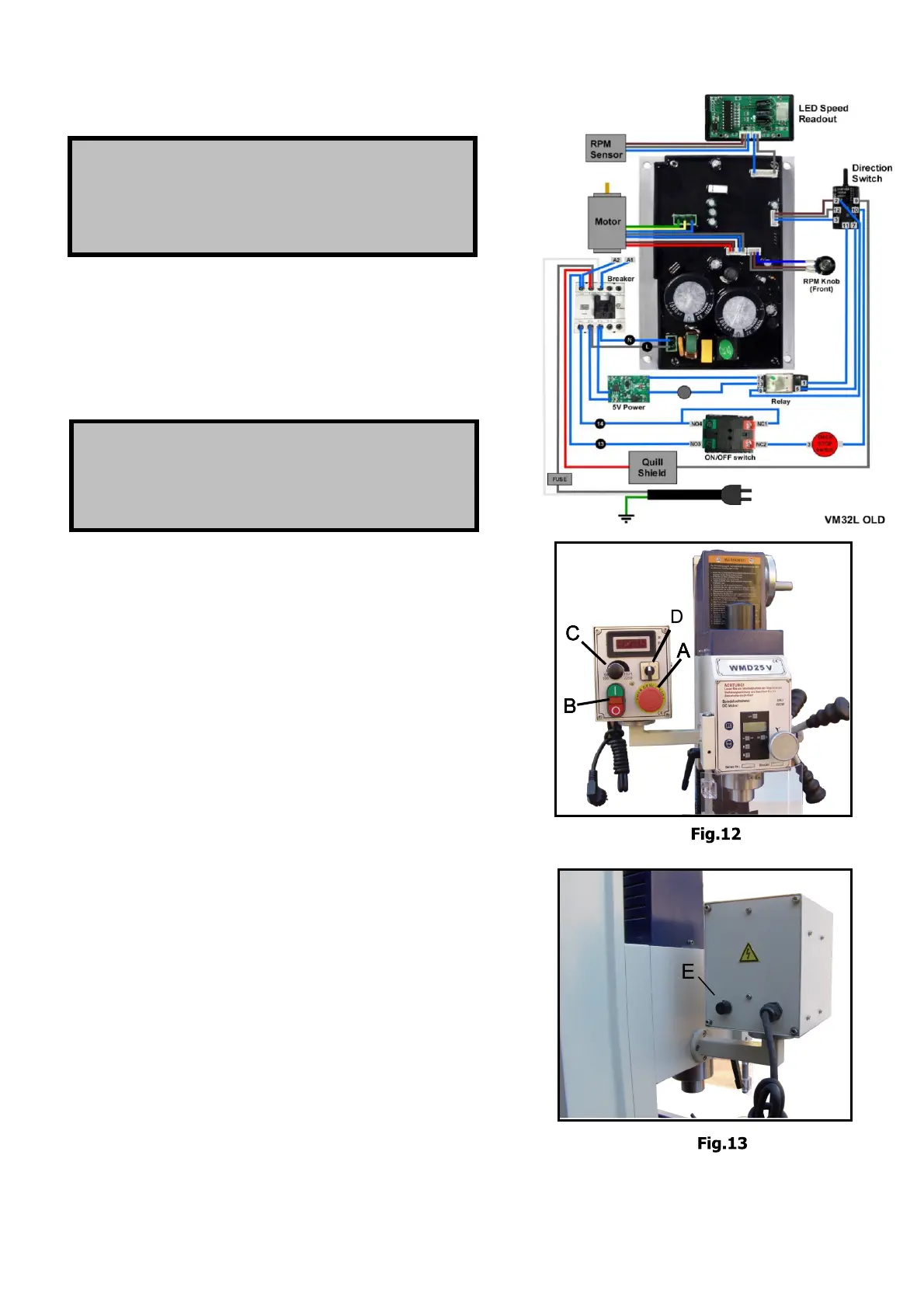

ELECTRICAL CONNECTIONS

Emergency stop switch (A,Fig. 12 )has the function of

emergency stopping and the protective function to the

machine and electric components.

On/off Switch (B,Fig.12) Green push button marked

“I” to start the motor, Red push button marked “O” to

switch the motor off.

Speed control knob (C,Fig. 12) turn it clockwise to

increase the spindle speed, reverse to decrease. The

knob should be turned to zero each time the machine

is stopped. Always start the machine with the knob

is stopped. Always start the machine with the knob

set at zero.

F/R switch(D, Fig.12)changing the postion of switch

Will reverse the direction of the motor. F-forward

Direction, R- reverse direction.

Fuse Base (E, Fig. 13) Located on the back plate of

electrical box. Fuse what rate is 10A is put in the base.

Turn counter-clockwise the button to open and

Change the fuse, reverse to retighten

WARNING!

A qualified electrician must make all electrical

connection

s!

Failure to do so may cause serious injury!

Before connecting the machine to the mains, make sure

that the el

ectrical values of the mains supply are the

same as those for the machine

’s electrical components.

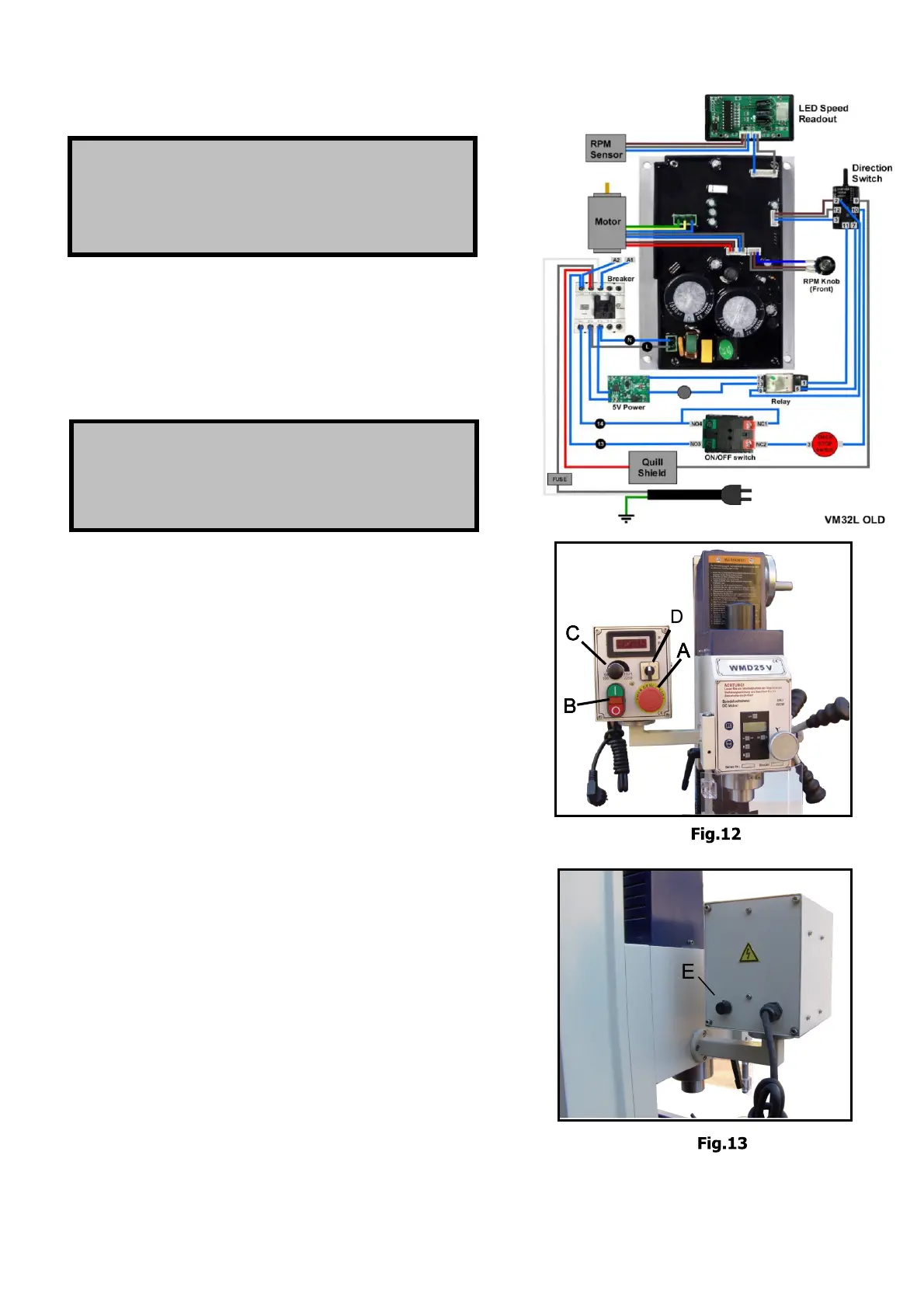

Use the wiri

ng diagram (Fig. 11) for connecting the lathe

to the mains suppl

y.

WARNING!

Make sure the machine is properly ground!

Failur

e

to do so may cause serious in

jury and

damage t

o user!

DC-Motor - its type is ,

Make sure that all

2 phase (L, N) are connected.

Defective or incorrect connection will render the

guar

antee null and void.

Indicators are:

Motor runs hot immediately (3-4 minutes).

Motor doesn’t run silently and has no power.

- 9 -

110V 1100W

Loading...

Loading...