52

XB8

PROBLEM CAUSE SOLUTION

ENGINE DOES NOT START

• Fuel tank is empty or carburetor is not primed

• Bad glowplug or dead glowdriver battery

• Fuel lines, fuel filter, air cleaner, or muffler is clogged

• Engine is flooded due to over-priming

• Carburetor is not adjusted properly

• Throttle servo linkage not adjusted properly

• Fill fuel tank with fuel and prime

• Replace glowplug or recharge/replace glowdriver battery

• Clean or replace clogged part(s)

• Remove glowplug, turn car over to discharge fuel from cylinder. Test glowplug and replace if defective

• Set idle and main/slow needle adjusting screw to standard starting position

• Move throttle servo to neutral position and re-adjust linkage(s)

ENGINE STARTS BUT

THEN STALLS

• Fuel tank is empty

• Fuel lines, fuel filter, air cleaner, or muffler is clogged

• Carburetor is not adjusted properly

• Engine has overheated

• Fill fuel tank with fuel

• Clean or replace clogged part(s)

• Re-adjust idle and main/slow needle adjusting screw

• Allow engine to thoroughly cool down and open main needle adjusting screw 30° turn richer (CCW)

BAD REACTION AND RESPONSE

FROM ENGINE

• Carburetor is not adjusted properly

• Fuel lines, fuel filter, air cleaner, or muffler is clogged

• Low fuel pressure from muffler

• Re-adjust main/slow needle adjusting screw

• Clean or replace clogged part(s)

• Properly install pressure line between muffler and fuel tank

CAR IS HARD TO CONTROL

• Weak transmitter and/or receiver batteries

• Low reception from radio antennas

• Servo linkages not adjusted properly

• Recharge or replace batteries

• Fully extend transmitter and receiver antennas

• Move servo to neutral then re-adjust linkage(s)

STEERING DOES NOT WORK

PROPERLY

• Weak transmitter and/or receiver batteries

• Bent linkages or driveshafts

• Loose steering components

• Drivetrain damage

• Recharge or replace batteries

• Check tightness of steering components and tighten if necessary

• Replace damaged parts

HANDLING PROBLEMS

• Shocks are not working properly

• Suspension is binding

• Improper tires

• Rebuild the shocks and replace worn or broken parts

• Make sure suspension moves freely. Replace worn or broken parts

• Use different tires

STEERING FEELS SLUGGISH

OR VAGUE

• Suspension is binding

• Damaged steering servo

• Make sure suspension moves freely, and replace worn or broken parts

• Check the steering servo for damage and wear, and replace/repair if necessary

THE CAR DOES NOT DRIVE

STRAIGHT

• Suspension is binding

• Steering trim is off-center

• Wheels are loose

• Damaged steering servo

• Make sure suspension moves freely, and replace worn or broken parts

• Adjust steering trim until car drives straight

• Check the make sure the wheel nuts are properly tightened

• Check the steering servo for damage and wear, and replace/repair if necessary

TROUBLESHOOTING GUIDE

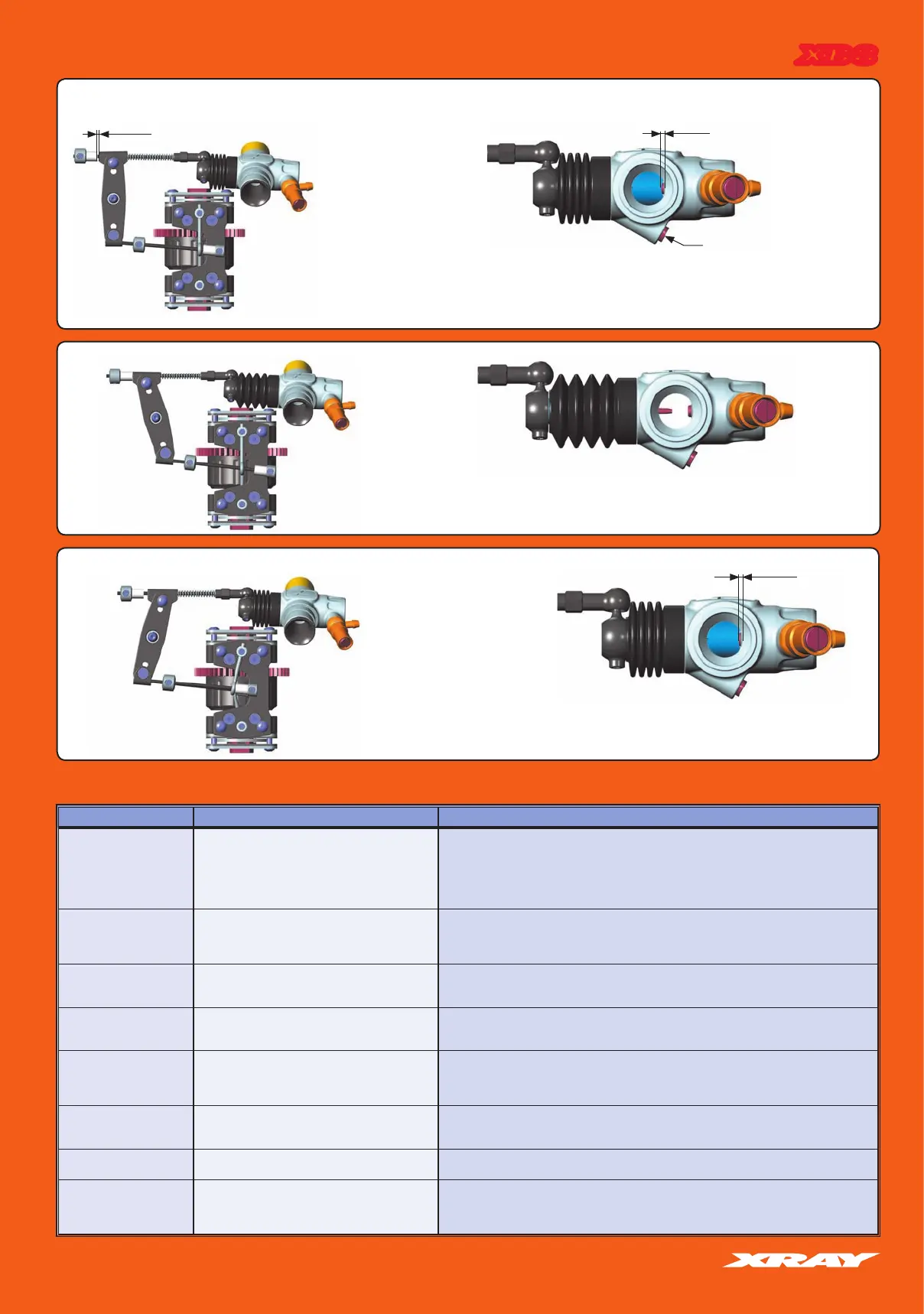

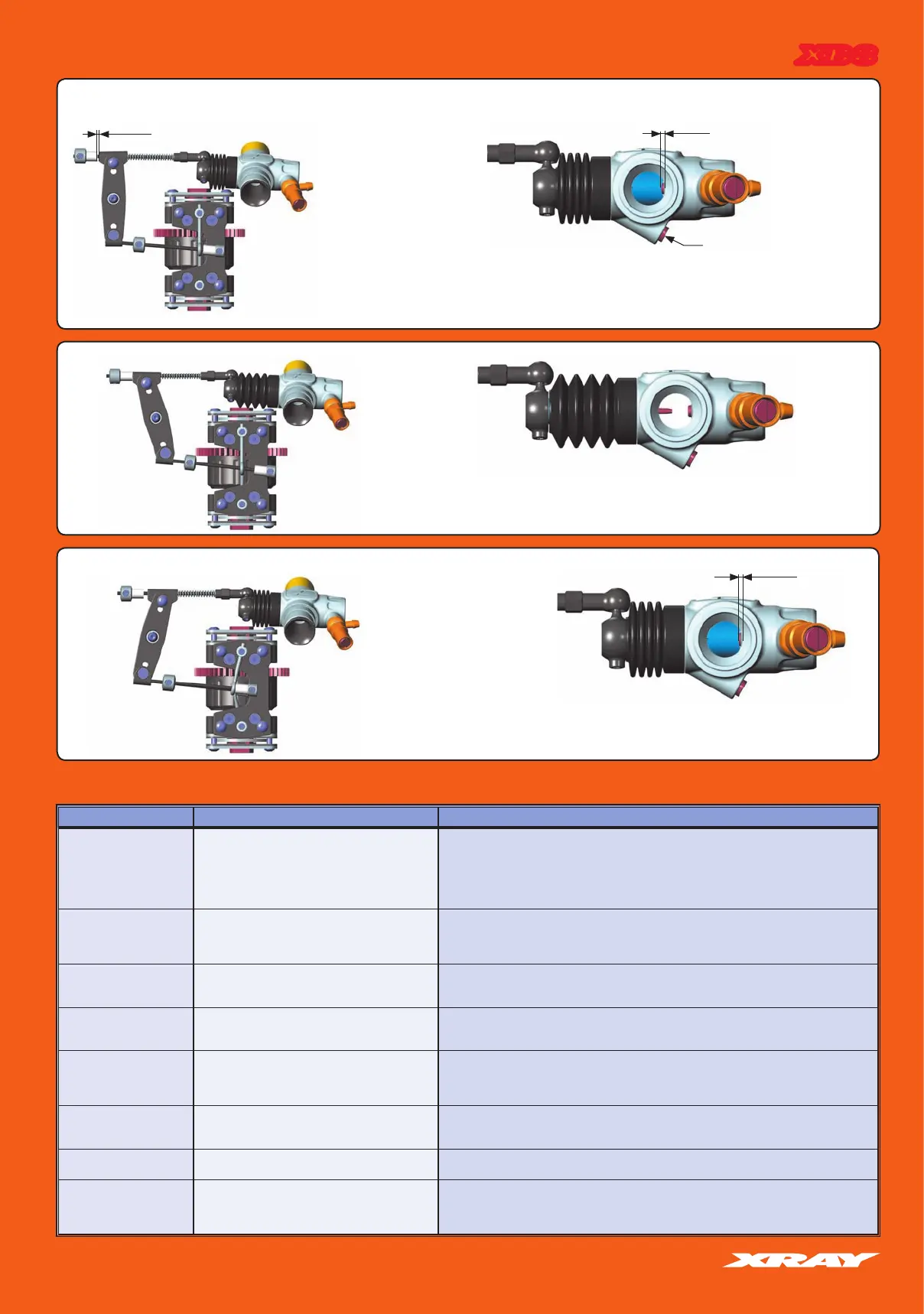

FULL THROTTLE

• Adjust the servo-horn mounting position for the carburetor to open fully.

• Change the pivot mounting position on the servo horn in case the carburetor is not opening fully or if it is opening excessively.

Or if available on the transmitter, adjust the throttle high end point.

BRAKE ADJUSTING KNOBS:

Upper linkage - rear brake

Lower linkage - front brake

cca 1mm

BRAKE

• Adjust the adjustable collars so the brakes work smoothly.

• If the brakes apply too much or not enough, adjust the adjustable collars accordingly. Or if available on the transmitter, adjust the brake endpoint.

• To tighten brakes, turn collar to thread brake rod INTO pivot.

• To loosen brakes, turn collar to thread brake rod OUT of pivot.

ENGINE IDLING

• Turn on the transmitter and receiver and set the engine control servo trim to the neutral position.

• Adjust the idle adjustment screw on the carburetor to open approx. 1mm.

• Adjust both the throttle linkage and brake linkages accordingly.

• DO NOT adjust the linkage with the engine running.

NEUTRAL (IDLE)

0.5mm

ADJUST INDIVIDUAL LINKAGES SEPARATELY TO AVOID INTERFERING WITH THE OPERATION OF THE OTHERS

~1mm

ENGINE IDLING

IDLING ADJUSTMENT SCREW.

Use to adjust the idle setting of the

carburetor. Do not allow carburetor to

close to less than 1mm.

THROTTLE LINKAGE ADJUSTMENT

Loading...

Loading...