SERVICE ACCESS

Access to all serviceable components is provided by the follow

-

ing removable panels:

•

Blower service access

•

Electrical/Filter access

•

Compressor service access

Refer to Figure 3 for location of these access panels and mini

-

mum clearances.

THERMOSTAT

The room thermostat should be located on an inside wall ap

-

proximately 56" above the floor where it will not be subject to

drafts, sun exposure or heat from electrical fixtures or appli

-

ances. Follow manufacturer's instructions enclosed with the

thermostat for general installation procedure. Six color coded

insulated wires (minimum #18 AWG) should be used to con

-

nect thermostat to unit. See Figure 2.

POWER AND CONTROL WIRING

Field wiring to the unit must conform to provisions of the cur

-

rent N.E.C. ANSI/NFPA No. 70 or C.E.C. and/or local ordi

-

nances. The unit must be electrically grounded in

accordance with local codes or, in their absence, with the

N.E.C./C.E.C. Voltage tolerances which must be maintained

at the compressor terminals during starting and running con

-

ditions are indicated on the unit Rating Plate and Table 3.

The wiring entering the cabinet must be provided with me

-

chanical strain relief.

A fused disconnect switch should be field provided for the unit.

If any of the wire supplied with the unit must be replaced, re

-

placement wire must be of the type shown on the wiring dia

-

gram.

Electrical line must be sized properly to carry the load. Each

unit must be wired with a separate branch circuit fed directly

from the meter panel and properly fused.

Refer to Figure 2 for typical field wiring and to the appropriate

unit wiring diagram for control circuit and power wiring informa

-

tion.

COMPRESSORS

Units are shipped with compressor mountings factory-

adjusted for shipping. Caution: Loosen compressor bolts

half turn before operating unit.

.

035-16004-001-A-0202

4 Unitary Products Group

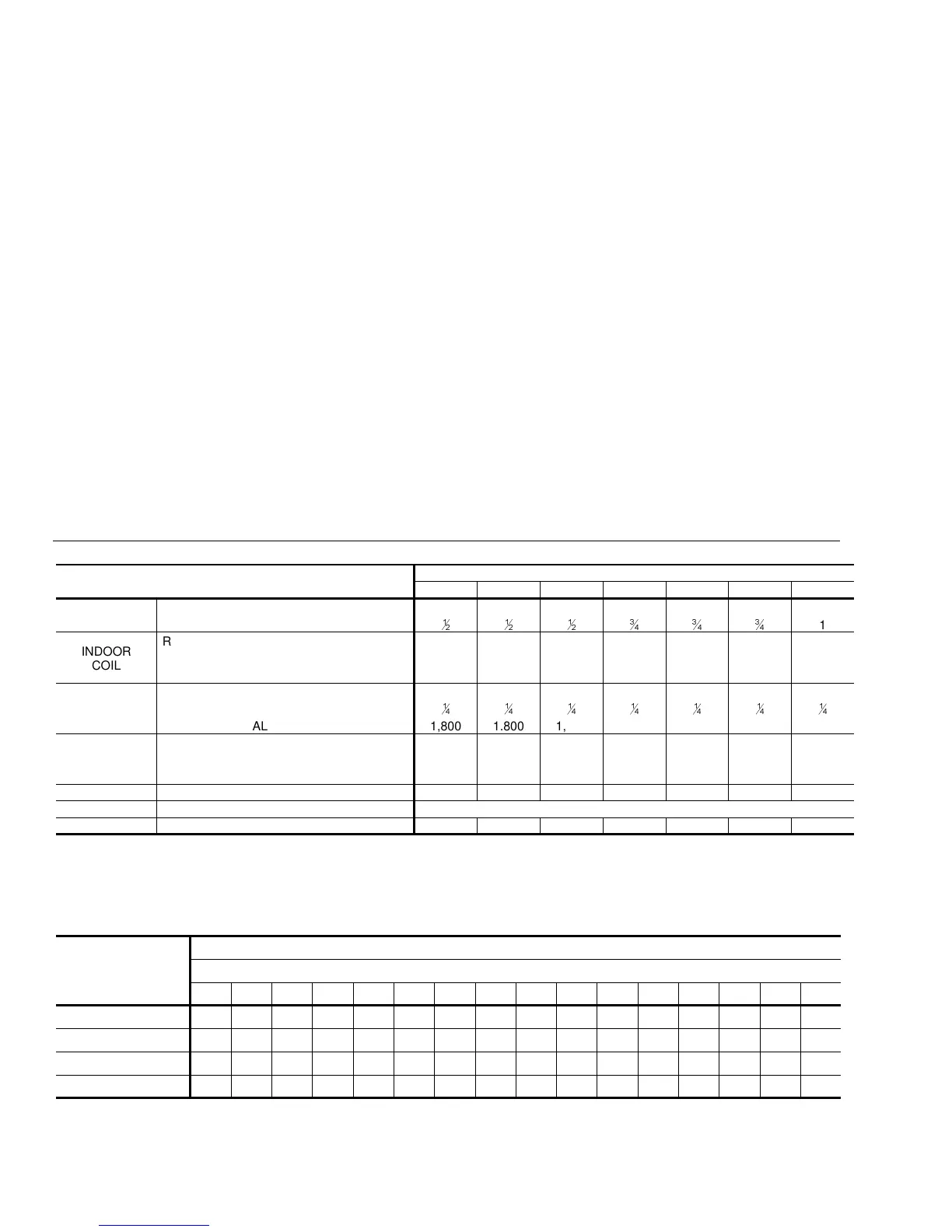

TABLE 2 - PHYSICAL DATA

MODELS

BHA

018 024 030 036 042 048 060

INDOOR

BLOWER

CENTRIFUGAL BLOWER (Dia. x Wd. in.) 9 X 6 10 X 8 10 X 8 10 x 8 11 X 10 11 X 10 11 X 10

FAN MOTOR HP (Three Speed)

1

2

1

2

1

2

3

4

3

4

3

4

1

INDOOR

COIL

ROWS DEEP 2233333

FINS PER INCH 15 13 13 15 15 16 16

FACE AREA (Sq. Ft.) 4.38 4.38 4.38 4.38 4.38 5.62 5.62

OUTDOOR

FAN

PROPELLER DIA. (in.) 22 22 22 22 22 22 22

FAN MOTOR HP

1

4

1

4

1

4

1

4

1

4

1

4

1

4

NOM. CFM TOTAL 1,800 1.800 1,800 2,400 2,400 2,800 2,800

OUTDOOR

COIL

ROWS DEEP 1111111

FINS PER INCH 20 20 20 20 20 16 20

FACE AREA (Sq. Ft.) 8.3 11.7 11.7 11.7 11.7 16.4 16.4

CHARGE REFRIGERANT 22 (lbs./oz.) 4 / 12 5 / 12 7 / 8 5 / 5 5 / 5 9 / 0 10 / 0

FILTER FACE AREA (Sq. Ft. / Qty. / Size) 4.28 / 2 / 14" x 22"

COMPRESSOR HERMETIC Type, (Qty. = 1)

Reciprocating Reciprocating Scroll Scroll Scroll Scroll Scroll

TABLE 3 - ADDITIONAL STATIC PRESSURE RESISTANCE

DISCRIPTION

RESISTANCE, IWG

CFM

500 600 700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600 1,700 1,800 1,900 2,000

Wet Indoor coil 0.01 0.01 0.01 0.02 0.02 0.03 0.03 0.04 0.04 0.04 0.04 0.04 0.05 0.05 0.06 0.07

Economizer 0.00 0.00 0.00 0.01 0.01 0.01 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.07 0.08 0.08

Filter/Frame Kit 0.01 0.02 0.02 0.02 0.02 0.02 0.03 0.03 0.03 0.03 0.04 0.05 0.05 0.06 0.06 0.07

Electric Heat 0.02 0.03 0.03 0.03 0.04 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.01 0.11 0.11 0.12

NOTE: 1. Deduct these resistance values from the available external static pressure shown in the respective Blower Performance Table.

2. The pressure thru the economizer is greater for 100% outdoor air then for 100% return air. If the resistance of the return air duct system is less then 0.25 IWG, the unit will deliver

less CFM during full economizer operation.