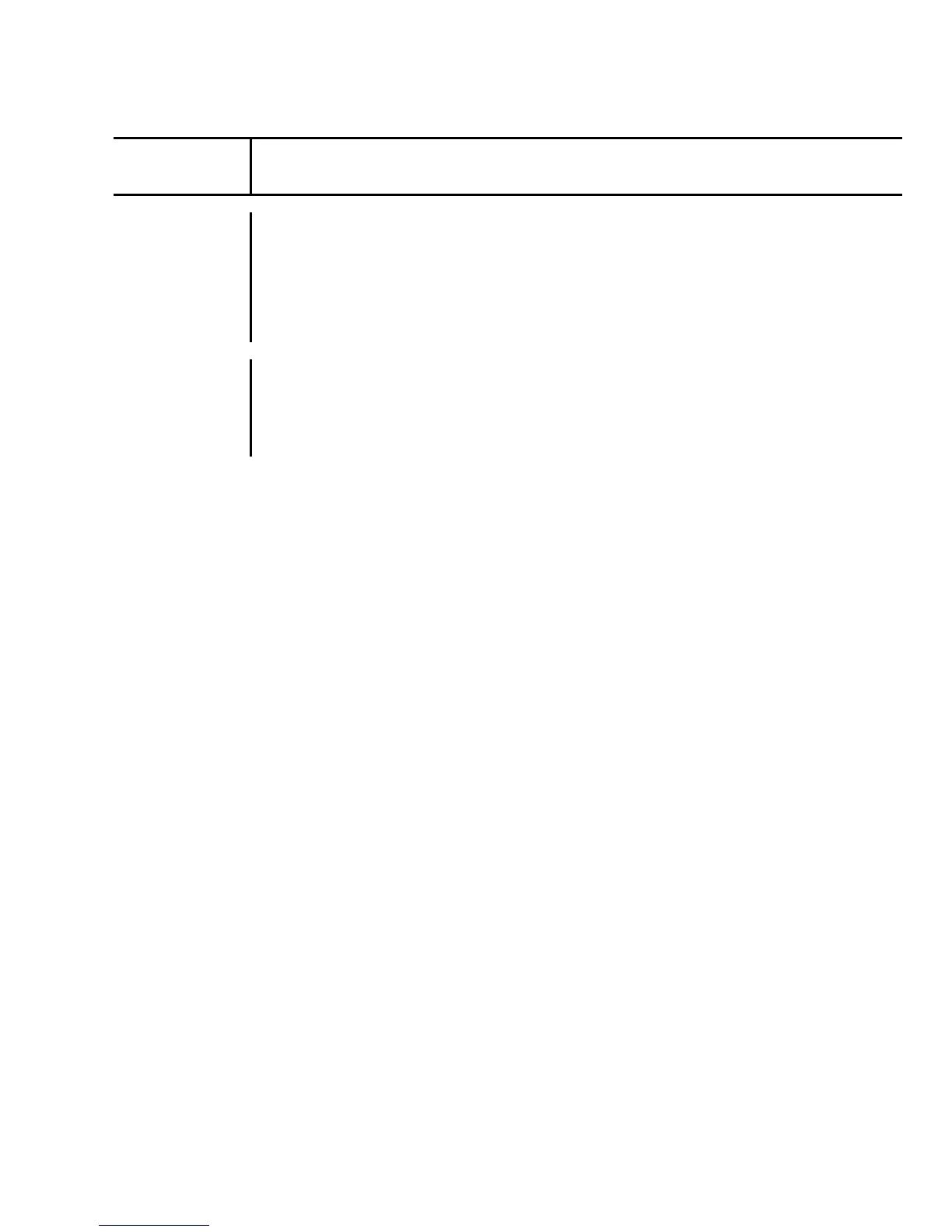

TABLE 7 - SUPPLY AIR BLOWER PERFORMANCE

BLOWER

SPEED,

(RPM)

MOTOR

PULLEY

(TURNS

OPEN)*

CFM

8,000 9,000 10,000 11,000 12,000

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

STANDARD DRIVE

1010 6.0** 1.6 7.6 6.4 1.0 8.9 7.5 0.5 10.4 8.7 - - - - - -

1064 5.0 1.9 8.2 6.9 1.4 9.6 8.0 0.9 11.1 9.3 0.3 12.7 10.6 - - -

1118 4.0 2.3 8.8 7.4 1.8 10.3 8.6 1.3 11.9 10.0 0.7 13.6 11.4 0.2 15.4 12.9

1172 3.0 2.7 9.4 7.9 2.2 11.0 9.2 1.7 12.7 10.6 1.1 14.5 12.2 0.5 16.4 13.7

1199 2.5 2.9 9.7 8.1 2.4 11.4 9.6 1.9 13.2 11.1 1.3 15.0 12.6 0.7 16.7 14.2

1226 2.0 3.1 10.0 8.4 2.6 11.8 9.9 2.1 13.6 11.4 1.5 15.5 13.0 - - -

1253 1.5 - - - 2.8 12.2 10.2 2.3 14.0 11.7 1.7 16.0 13.4 - - -

1280 1.0 - - - 3.0 12.6 10.6 2.5 14.5 12.2 2.0 16.6 13.9 - - -

HIGH SPEED DRIVE ACCESSORY

1118 6.0 2.3 8.8 7.4 1.8 10.3 8.6 1.3 11.9 10.0 0.7 13.6 11.4 0.2 15.4 12.9

1170 5.0 2.7 9.4 7.9 2.2 11.0 9.2 1.7 12.7 10.6 1.1 14.5 12.2 0.5 16.4 13.7

1222 4.0 3.1 10.1 8.4 2.6 11.8 9.9 2.1 13.6 11.4 1.5 15.5 13.0 - - -

1274 3.0 - - - 3.0 12.6 10.6 2.5 14.5 12.2 2.0 16.6 13.9 - - -

1300 2.5 ------2.714.912.5 2.2 17.2 14.4 - - -

1326 2.0 ------3.015.513.0 - - - - - -

NOTES: 1. Blower performance is based on cooling only unit, with fixed outdoor air, 2" T/A filters and a dry evaporator coil.

2. Refer to Page 14 for additional static resistances.

ESP = External Static Pressure available for the supply and return air duct system. All internal unit resistances have been deducted from the total static pressure of the blower.

* Do

NOT close the pulley below 1 turn open.

** Factory setting.

DCE300 - BOTTOM DUCT CONNECTIONS (COOLING APPLICATIONS)

530.18-N11Y

Unitary Products Group 13

Loading...

Loading...