10 Unitary Products Group

035-16192-001-A-1001

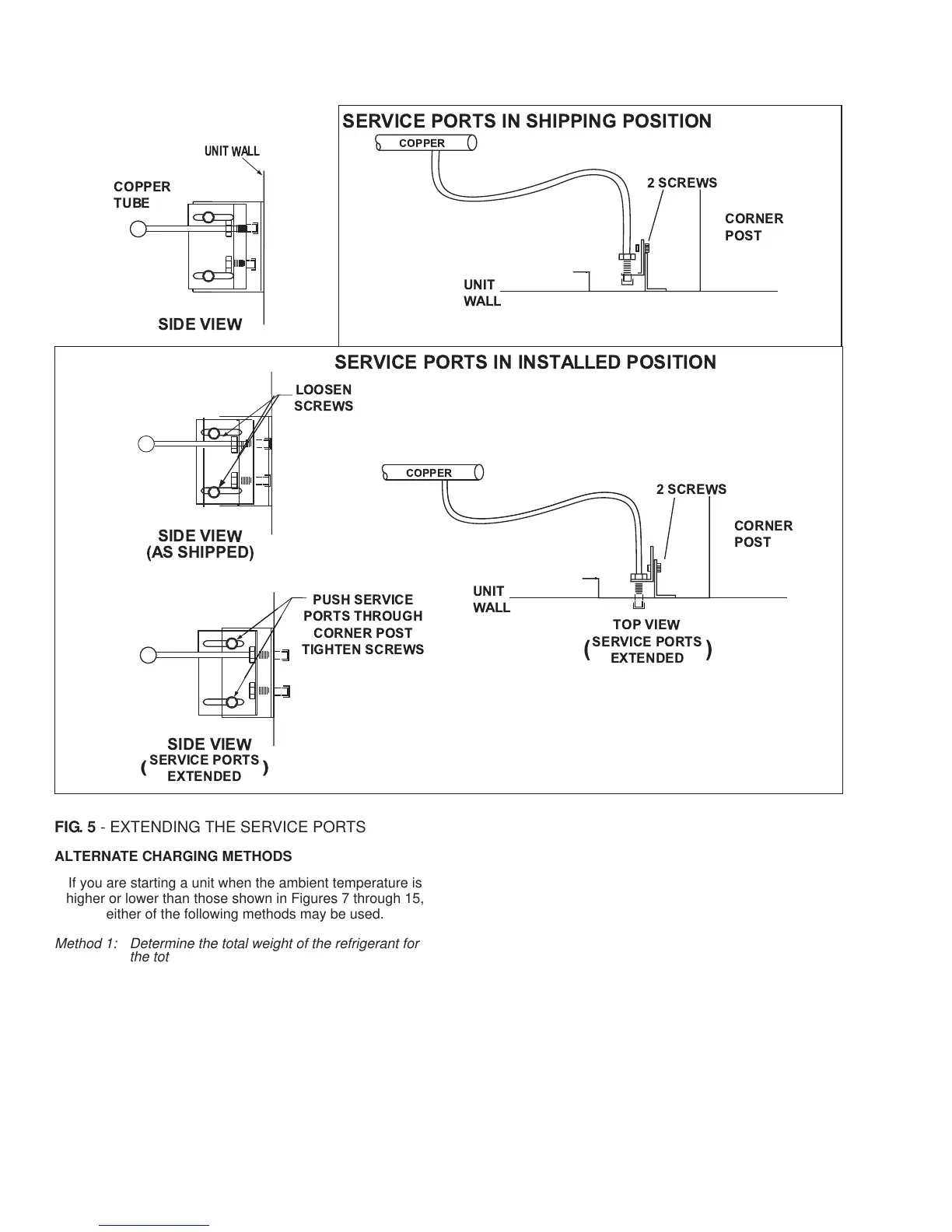

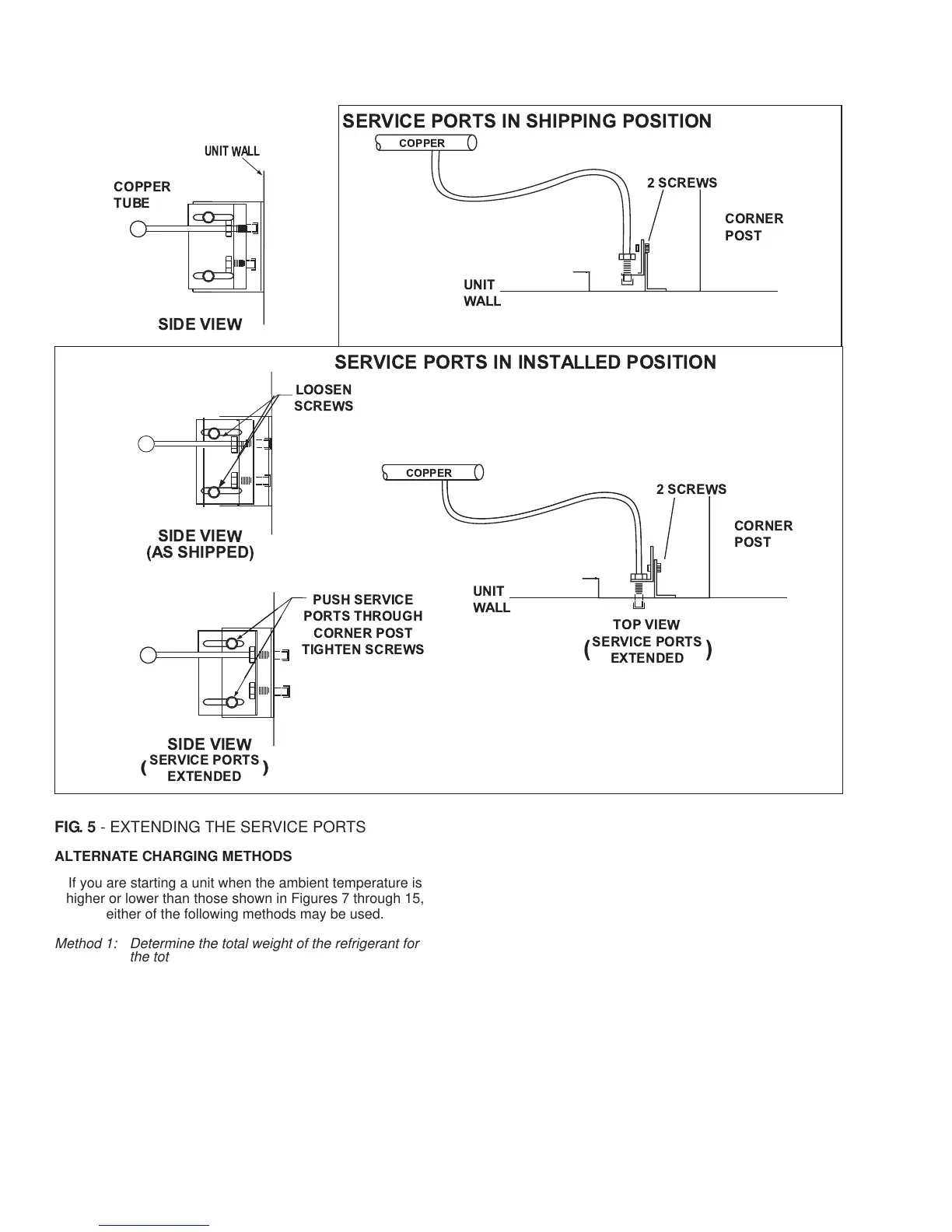

COPPER

2SCREWS

CORNER

POST

SERVICE PORTS IN SHIPPING POSITION

UNIT WALL

SIDE VIEW

COPPER

TUBE

UNIT

WALL

COPPER

2SCREWS

CORNER

POST

TOP VIEW

UNIT

WALL

LOOSEN

SCREWS

SIDE VIEW

(AS SHIPPED)

PUSH SERVICE

PORTS THROU GH

CORNER POST

TIGHTEN SCREWS

SIDE VIEW

SERVICE PORTS

EXTENDED

()

SERVICE PORTS

EXTENDED

()

SERVICE PORTS IN INSTALLED POSITION

FIG. 5 - EXTENDING THE SERVICE PORTS

ALTERNATE CHARGING METHODS

If you are starting a unit when the ambient temperature is

higher or lower than those shown in Figures 7 through 15,

either of the following methods may be used.

Method 1: Determine the total weight of the refrigerant for

the total system by adding the required charge

for the outdoor unit, the indoor unit and the refrig

-

erant lines using information in Tables 2 (Physi

-

cal Data) and 6 (Refrigerant Line Charge).

Using the charging procedures outlined above,

weigh the required amount of refrigerant charge

into the unit.

Method 2:

Install a field supplied moisture indicating sight

glass in the liquid line between the filter-drier and

the evaporator coil.

Using the charging procedure outlined above,

charge refrigerant until the moisture indicating

sight glass is clear. Add approximately 2 extra

pounds of refrigerant to assure a liquid refrigerant

seal at the expansion valve under all operating

conditions. Block the flow of the condenser air, if

necessary, to assure a head pressure of 280 psig

during the charging procedure.

Note: The installer should return to the job to verify the operat

-

ing charge when the ambient temperature is within the

conditions shown in Figures 7 through 15.

Loading...

Loading...