841890-UIM-B-0612

4

LIMITATIONS

These coils should be installed in accordance with all national and local

safety codes.

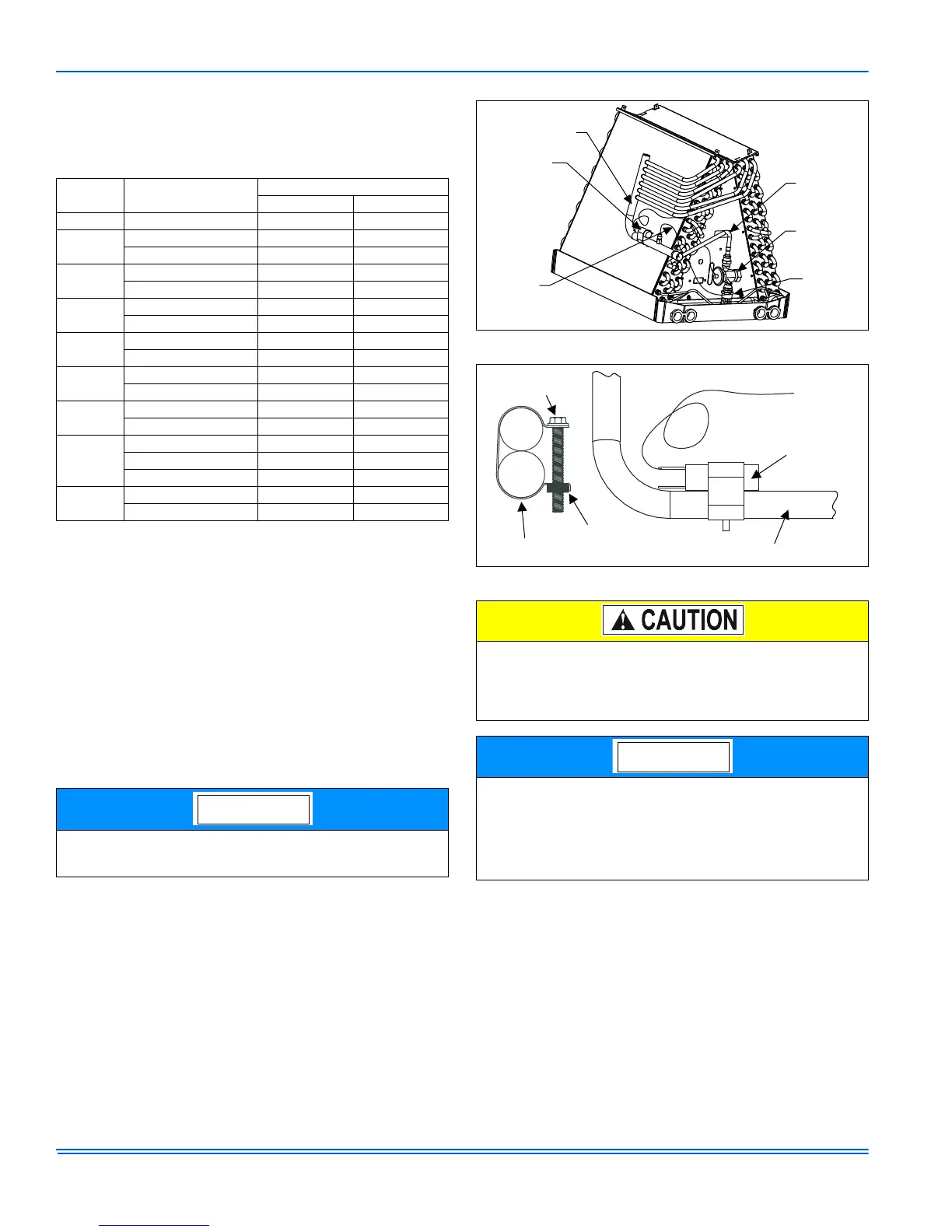

SECTION III: COIL METERING DEVICES

An orifice or a TXV to be installed in the field. Refer to installation man-

ual with TXV kit. It is recommended to install the orifice or TXV kit prior

to installation of coil in cabinet and brazing line sets.

Consult the outdoor installation guide for outdoor units that require an

orifice as a metering device for the indoor coil. The orifice and the

Schraeder core are supplied with the outdoor unit. Install Schraeder

core in the suction line Schraeder body and cap with the supplied plas-

tic cap.

TXV METERING DEVICE

Please refer to Technical Guide to verify which TXV is installed in this

coil and that this is a valid system match for the AC or HP unit installed.

The temperature sensing bulb is attached to the coil suction header

line.

TABLE 4:

Coil Air Flow Limits

Coil

Size

Outdoor Unit

Tons

CFM Limits

Minimum Maximum

18 1-1/2 525 675

24

1-1/2 525 675

2 700 900

30, 32

2 700 900

2-1/2 875 1125

35

2-1/2 875 1125

3 1050 1200

36, 37

2-1/2 875 1125

3 1050 1350

42

3 1050 1350

3-1/2 1225 1575

43

3 1050 1350

3-1/2 1225 1575

48

3 1050 1350

3-1/2 1225 1575

4 1400 1800

60, 62, 64

4 1600 1800

5 1750 2250

For models that have factory installed TXV’s, take caution not to

apply high temperatures to the TXV assembly or equalizer line

while brazing.

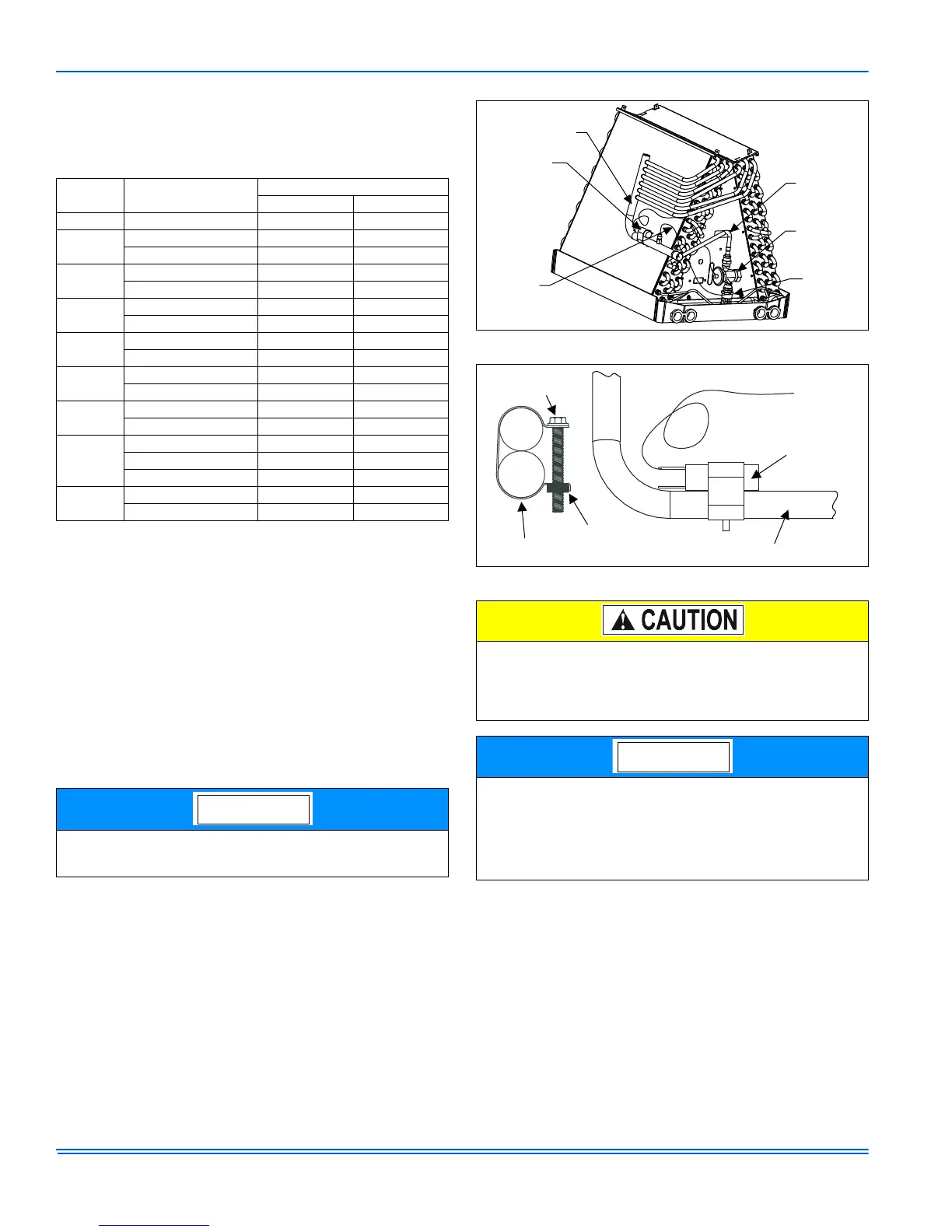

FIGURE 3: TXV Bulb Installation

FIGURE 4: Proper Bulb Location

COIL UNDER PRESSURE.

Relieve pressure by depressing schrader stem. Coil may have fac-

tory installed TXV or may require orifice or TXV to be added. See

outdoor unit documentation for correct orifice or TXV to be used.

Refer to coil nameplate for orifice or TXV identification for this unit.

The coil should be open to the air for no more than 2 minutes to

keep moisture and contaminates from entering the system. If the

coil cannot be brazed into the refrigeration system in that time, the

ends should be temporarily closed or plugged. For a short term

delay, use masking tape over the ends of the copper tubing to close

the tube to the air. For a longer term delay, use plugs or caps.

There is no need to purge the coil if this procedure is followed.

Vapor

Line

Thermal

Expansion

Valve Bulb

Thermal

Expansion

Valve

Distributor

Body

Liquid

Line

TXV

Equalizer

Line

(Wrapped with

insulation)

TXV BULB

(Cover completely

with insulation)

SCREW

CLAMP

NUT

SUCTION LINE

Loading...

Loading...