FORM NO.: 6U5M-A11M-NB-EN

JOHNSON CONTROLS 47

MODBUS PROTOCOL

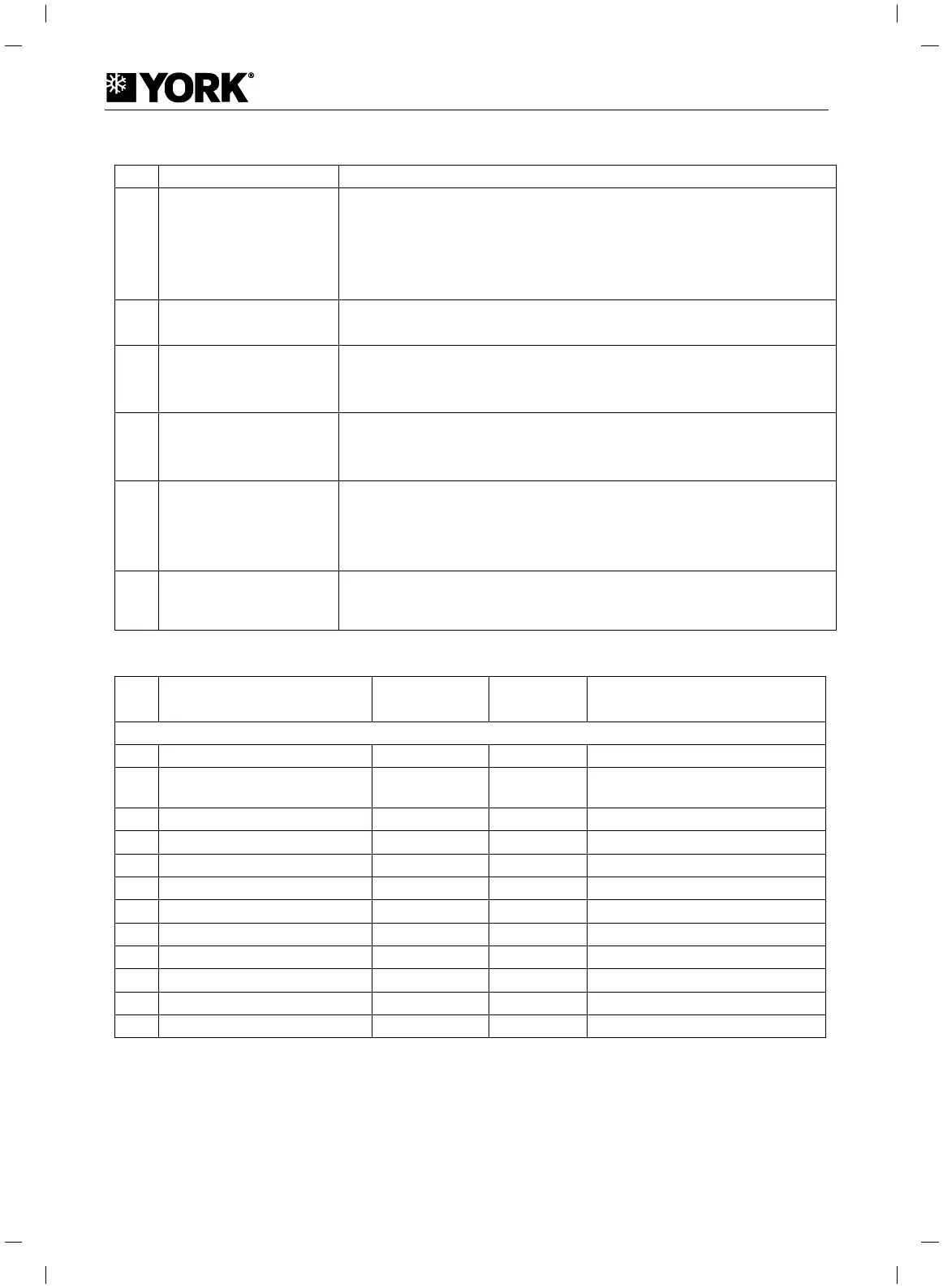

TABLE 15 - DEFINITIONS

NO.

ITEM DESCRIPTION

1 Data Flow

Communication Baud rate: 9600bps;

8-N-1: 1 start bit,1 stop bit, check bit-none, 8 data bits;

Modbus-RTU Protocol;

CRC: Cyclic Redundancy Check;

Hexadecimal data.

2 Master - Slave

Modbus as master;

1# microboard as slave.

3 Temperature

Unit: 0.1℃

Actual temperature=Register value/10

e.g.: Cooling LWT=81, then the actual temperature is 8.1℃

4 Read/Write Mechanism

BAS need to keep communication with mainboard periodically;

BAS parameter setpoint may exceed unit default range and it is required for BAS to

read the setpoints from the mainboard.

5 BAS Enable

The BAS Modbus addresses of subordinates are set through HMI;

Set DIP 301-7 to “ON” to make BAS enable.

Set the corresponding parameters in HMI to enable and disable the BAS Start/Stop

and Operating Mode functions.

6 Start/Stop Status

The Start/Stop Command (Register value = 0) is only used to start/stop the unit;

Actual Start/Stop Status is accessible by reading Register value = 100.

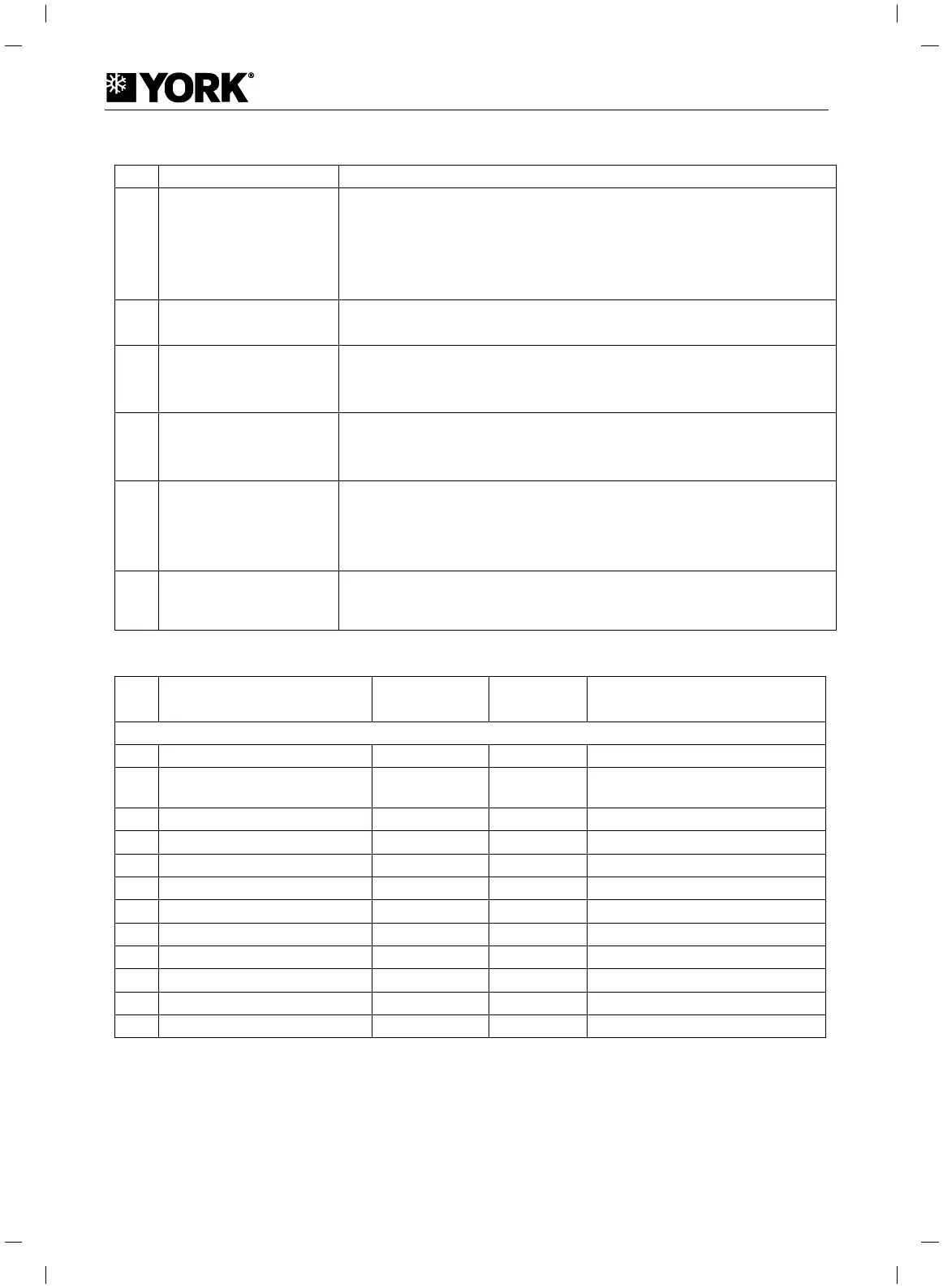

TABLE 16 – SYSTEM SETPOINTS

NO.

Name Function Code

Register

Address

Note

System Setpoints

1 Chiller ON/OFF 3, 6, 16 0 0-Invalid, 1-On, 2-Off

2 Mode Setting 3, 6, 16 1 0-Cooling, 1-Heating, 8-Only Pump

3 Cool Return WT Setpoint 3, 6, 16 2 10~30

4 Heat Return WT Setpoint 3, 6, 16 3 25~50

5 Cool Leaving WT Setpoint 3, 6, 16 4 5~25

6 Heat Leaving WT Setpoint 3, 6, 16 5 30~55

7 Low Sound Mode 3, 6, 16 7 1-Enabled

8 Fault Reset 3, 6, 16 8 1-Reset

9 Cooling Control Select 3, 6, 16 9 0-Fixed RT, 1-Fixed LT

10 Heating Control Select 3, 6, 16 10 0-Fixed RT, 1-Fixed LT

11 Temperature Control Cycle 3, 6, 16 11 20~120, Unit: s

12 Water Temp. Control Diff. 3, 6, 16 12 1~3

Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz

Loading...

Loading...