60 OI/266/HART-EN Rev. M | 2600T Series Pressure transmitters

8 Operation

For additional information, refer to the operating instructions

included with the handheld terminal.

If the transmitter has been configured in the factory according

to customer specifications for the measuring point, all you have

to do is mount the transmitter as prescribed (to correct

potential zero shifts, refer to the section “Correcting the zero

shift”), and switch it on. The measuring point will now be ready

for use.

If, however, you wish to make changes to the configuration, a

handheld terminal or - preferably - a graphical user interface

(DTM) is required. This DTM tool renders the device fully

configurable. It supports both the HART protocol and

PROFIBUS PA fieldbus protocol, and can be run on a PC or

laptop, or as part of an automation system. Where

FOUNDATION Fieldbus is concerned, the device description

(DD), which can be loaded onto various configuration tools, is

required for configuration purposes.

Refer to the installation manual provided with the software for

the steps required to install the operating tool. The most

important parameters can be set via the path “Parametrize_

Differential Pressure Measurement”.

The program offers the option of configuring, polling, and

testing the transmitter.

In addition, offline configuration can be performed by means of

an internal database.

Each configuration step is subject to a plausibility check. You

can call up context-sensitive help at any time by pressing the

“F1” key. Immediately after you have received the transmitter or

before you change the configuration, we recommend that you

save the existing configuration data to a separate data storage

medium, via the path “File_Save”.

8.17 Configuration with the graphical user interface

(DTM) - System requirements

— Operating control program (e.g., ABB Asset Vision Basic

version 1.00.17 or higher)

— DTM (Device Type Manager; graphical user interface)

— Operating system (depending on the respective control

program)

To operate the Asset Vision Basic please refer to the relevant

operating instruction.

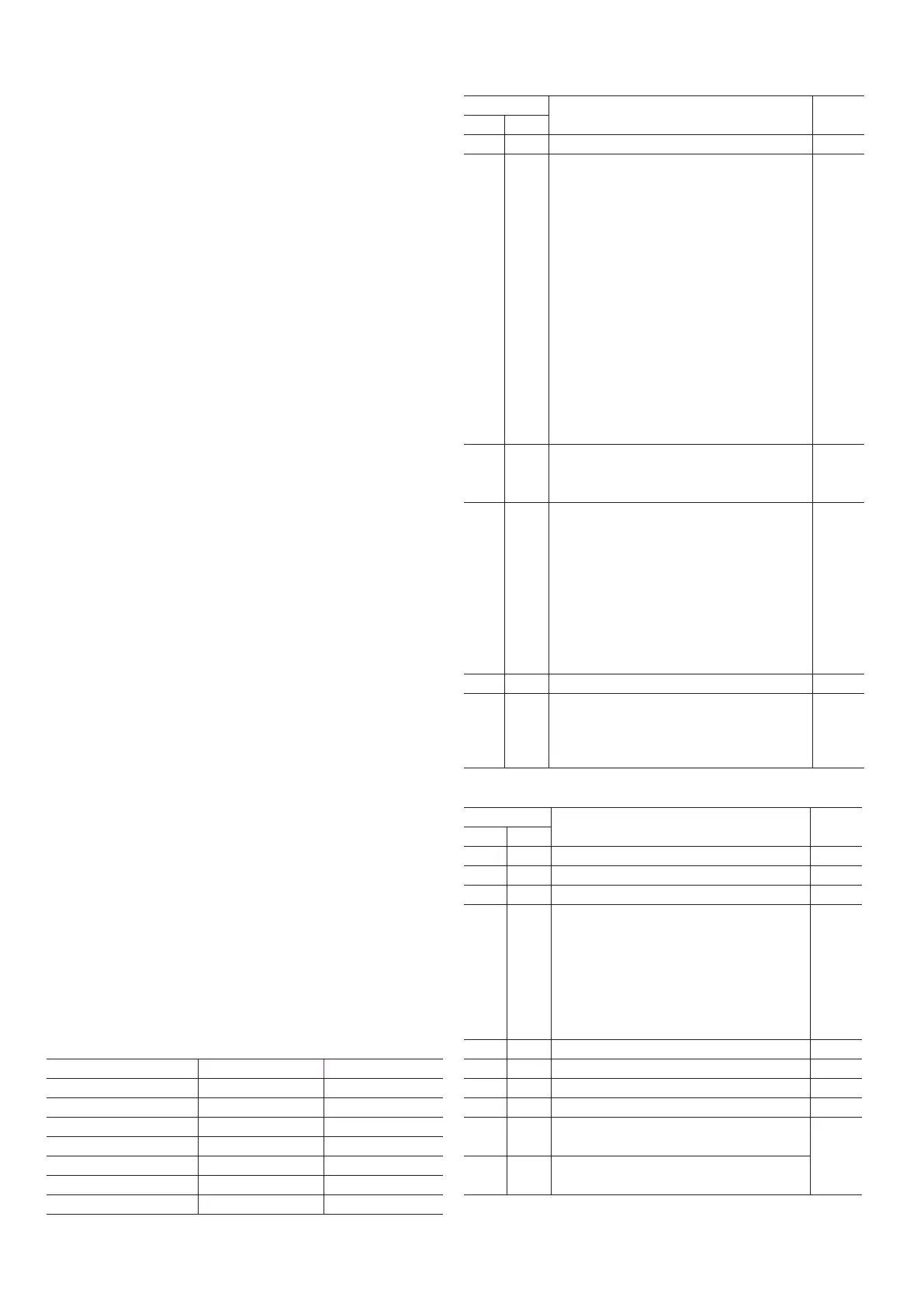

8.18 Standard and Advanced HART: functionality

266 Pressure Transmitters can be codified with:

— Advanced HART and 4 to 20 mA

— Standard HART and 4 to 20 mA

— HART and 4 to 20 mA Safety, certified to IEC 61508

Advanced and Standard HART feature some differencies in

terms of functionality.

Functionality 266 Advanced HART 266 Standard HART

Configuration via HMI On board Not available

SIL certified On board Not available

PILD On board On board

Trend On board Not available

Totalizer On board On board

Service Port On board Not available

Electronic replacement On board Not available

8.19 Advanced HART software revision history

Revision

Description

Release

date

From To

7.1.11 First release 09/2009

7.1.11 7.1.12

Bug Fixing:

— microbar and millitor units added

— HART command 35 bug fixed. By HART

specificaiton #35 unit should not be set pv unit

— if the local indicator was not mounted, only

one operation via push buttons was performed

— MWP diagnosis classification become

Maintenance instead of Off-Specification

Improvements:

— replacement functionality improved

— internal improvements to reduce factory

configuration

— more/stronger checks about process variables

goodness

— HART response time reduced (30%)

06/2010

7.1.12 7.1.14

Improvements:

— factory configuration speeded up

— service detailed diagnosis implemented

01/2011

7.1.14 7.1.15

Bug Fixing:

— sensor trimming via local display was

performend only in kPa

— diagnosis “Replace Error” no more shown

— unit strings on display (Nm3, bbl, t) were wrong

New Features:

— new language (French & Spanish) on local

indicator

— sensor polarity invertion

01/2013

7.1.15 7.2.1 HART 7 implementation 11/2015

7.1.15

7.2.1

7.1.16

(HART 5)

7.2.2

(HART 7)

New Features:

— Temperature alarm enabled by user

— oscillation alarm control

— switching of alarm for wrong power supply

10/2018

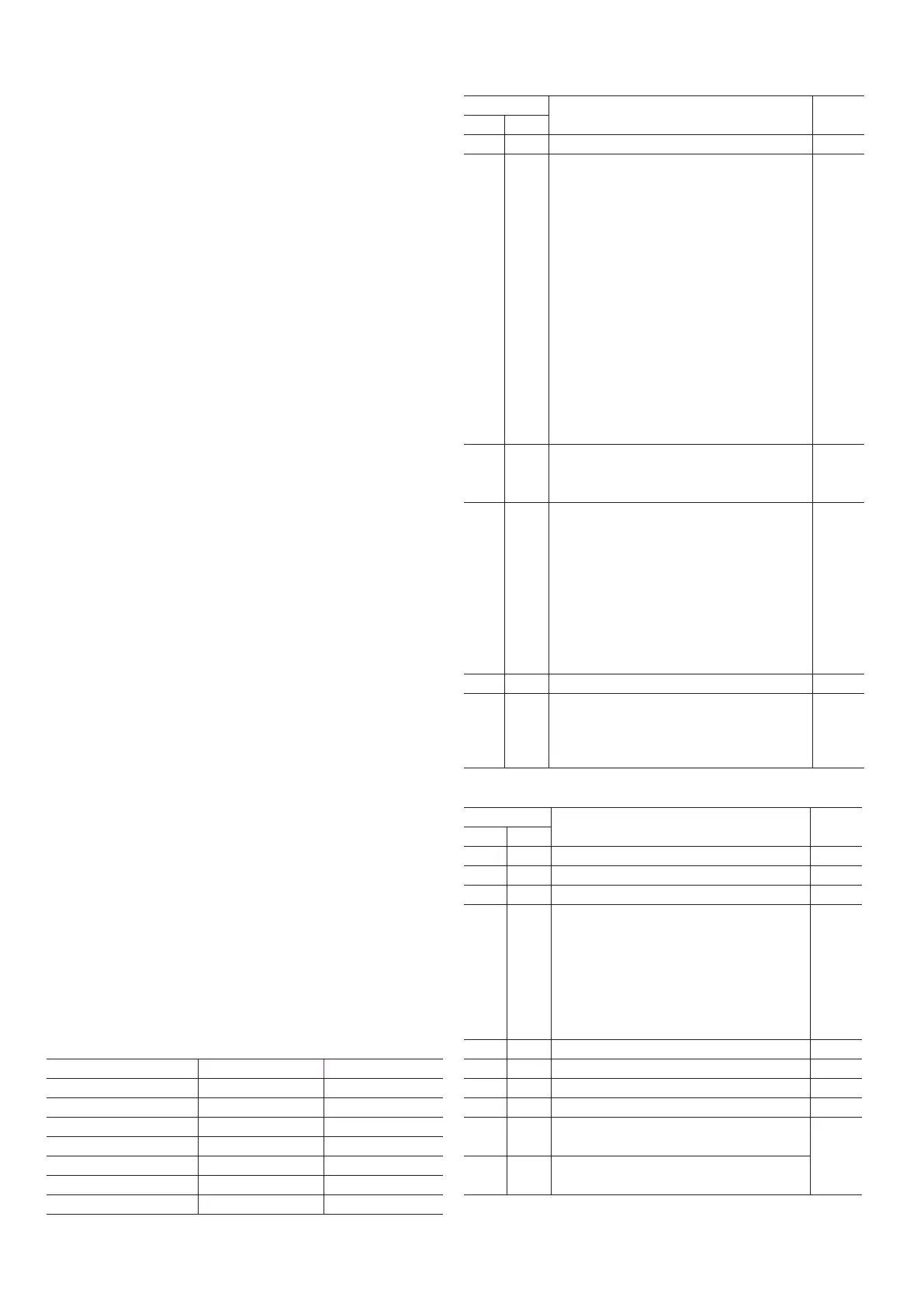

8.20 Standard HART software revision history

Revision

Description

Release

date

From To

7.1.50 First release 02/2013

7.1.51 Internal release not published

7.1.52 Internal release not published

7.1.52 7.1.53

Bug Fixing:

— HART burst mode

— correcting Custom unit visualization on LCD

Improvements:

— boot loader performance

— HART secondary response code

— Electronics temperature reading

01/2014

7.1.53 7.1.54 Integrated LCD firmware integration 07/2014

7.1.54 7.1.55 Bug fixing on EEPROM 10/2014

7.1.55 7.1.56 Obsolete Microprocessor replacement 06/2016

7.1.56 7.2.50 HART 7 Introduction 10/2016

7.1.56 7.1.74

(HART 5)

Several bug fixing

10/2018

7.2.50 7.2.54

(HART 7)

Several bug fixing and certification

HART burst mode removed

Intermediate releases for internal tests not published

Loading...

Loading...