Chapter 6 – Parameters

ACH 500 Programming Manual 6-23

1 SWITCHING FREQ

Motor noise can be minimized by adjusting the switching frequency to a

value that does not create resonances in the motor and load. The optimum

switching frequency is the lowest frequency where the noise is acceptable.

As the switching frequency goes up, the inverter efficiency goes down, so it is

best to use as low a switching frequency as possible relative to acceptable

noise levels for the particular application.

Note: Consult factory for derating information for increased switching

frequency above 3 kHz.

2 MAX OUTPUT

VOLTAGE

Maximum voltage that the drive will output at and above the Field Weakening

point. This parameter is automatically set to the same value as Start-up Data

Parameter K (Motor Nom. Voltage) when that parameter is changed. Set in

actual volts, step equals 1% of V

N

. Range is 0.15 – 1.05 x V

N

.

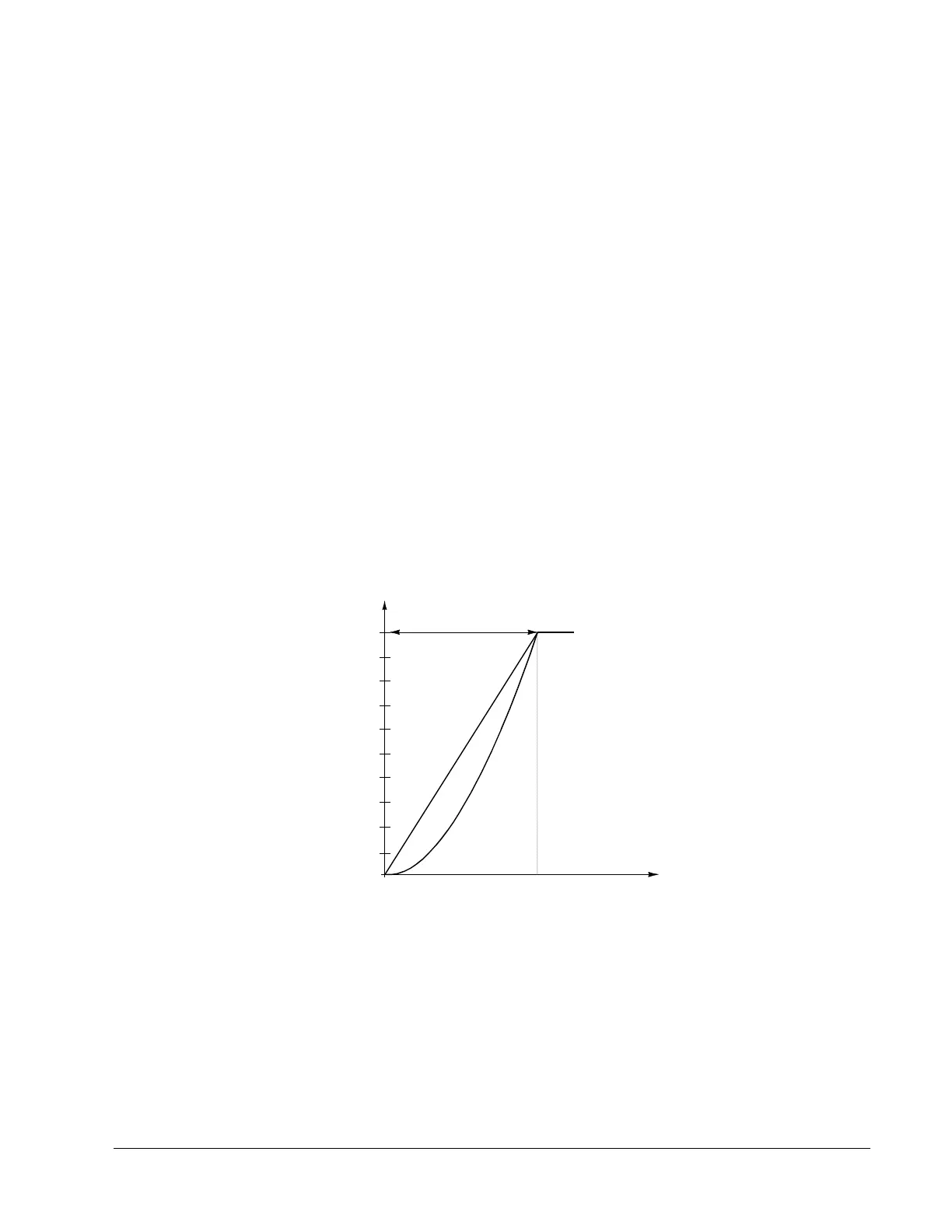

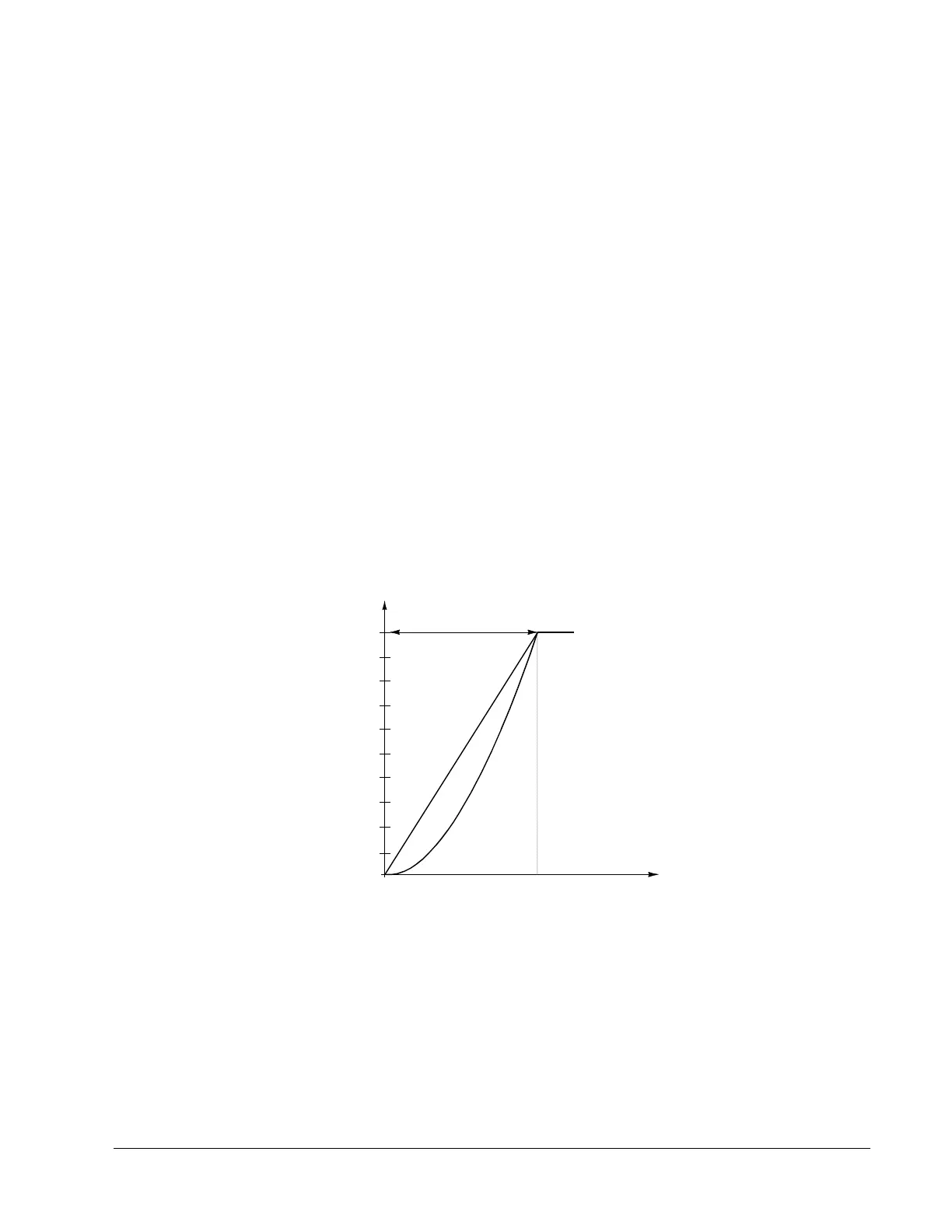

3 V/Hz RATIO

LINEAR

The voltage of the motor changes linearly with frequency in the constant

torque area. Linear V/Hz ratio is normally used in Torque control mode, or

where the torque characteristics of the load is constant with speed.

Figure 6-6 shows V/Hz ratios.

Figure 6-6 V/Hz Ratios

SQUARED

A squared V/Hz ratio undermagnetizes the motor, reducing noise and motor

losses. Squared V/Hz ratio is normally used in applications where the load

torque characteristic is proportional to the square of the speed, such as

centrifugal pumps, fans and compressor drives.

f [Hz]

0

Constant Torque Range

10

50

100

[%]

V

MAX /VN

Linear

V/Hz Ratio

Squared

V/Hz Ratio

Field Weakening Point

Loading...

Loading...