MOTORS FOR HEAVY ELECTRICAL VEHICLES

12

3. Transportation and Storage

3.1. Transportation

3.1.1. Delivery to customer

The traction motor is transported fastened to a pallet. Leave the traction motor on the pallet until it is

time to place it in its working place i.e., chassis.

During short term storage, place the traction motor so that it is out of the way of any other goods

handling and on a flat, vibration-free surface.

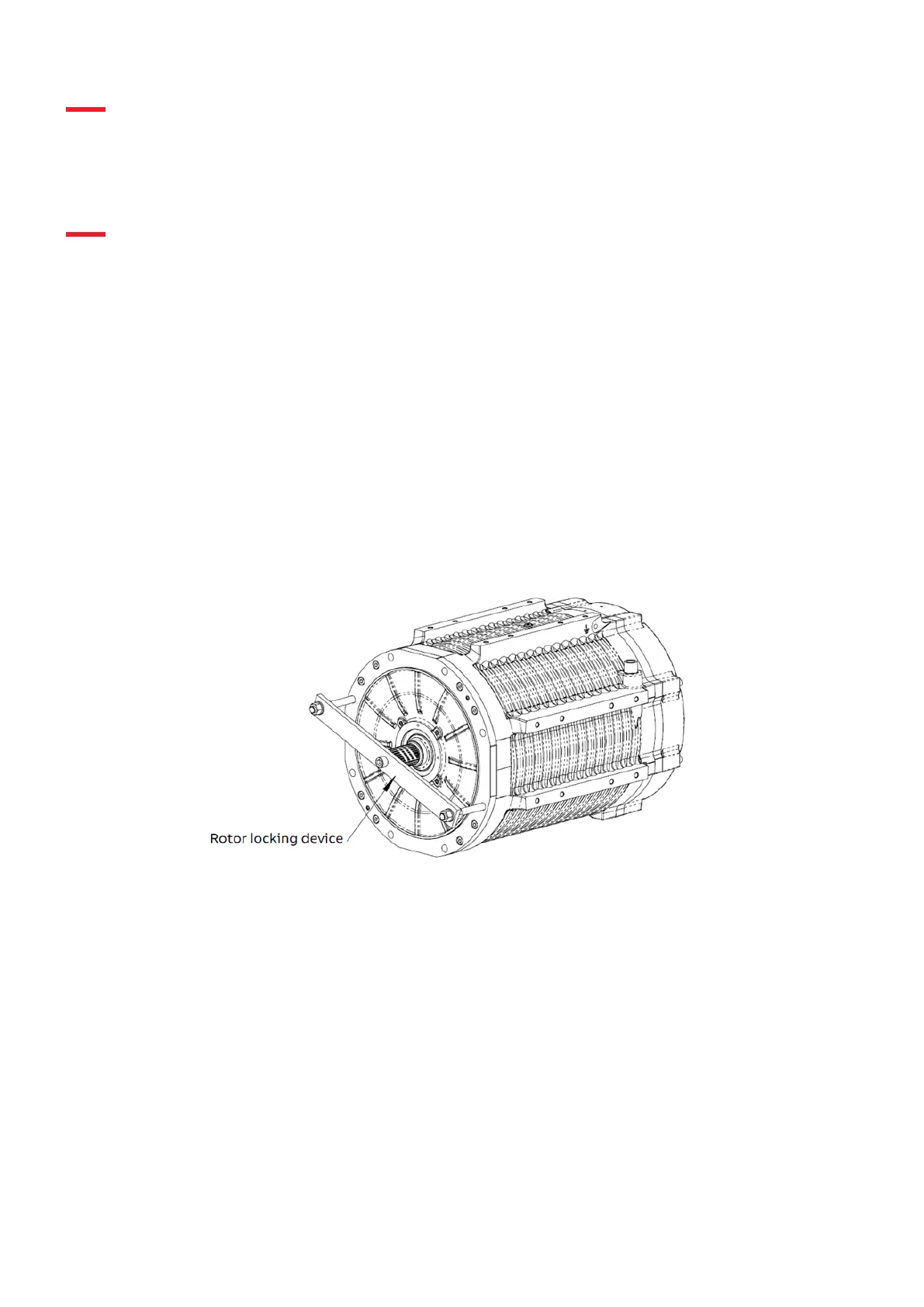

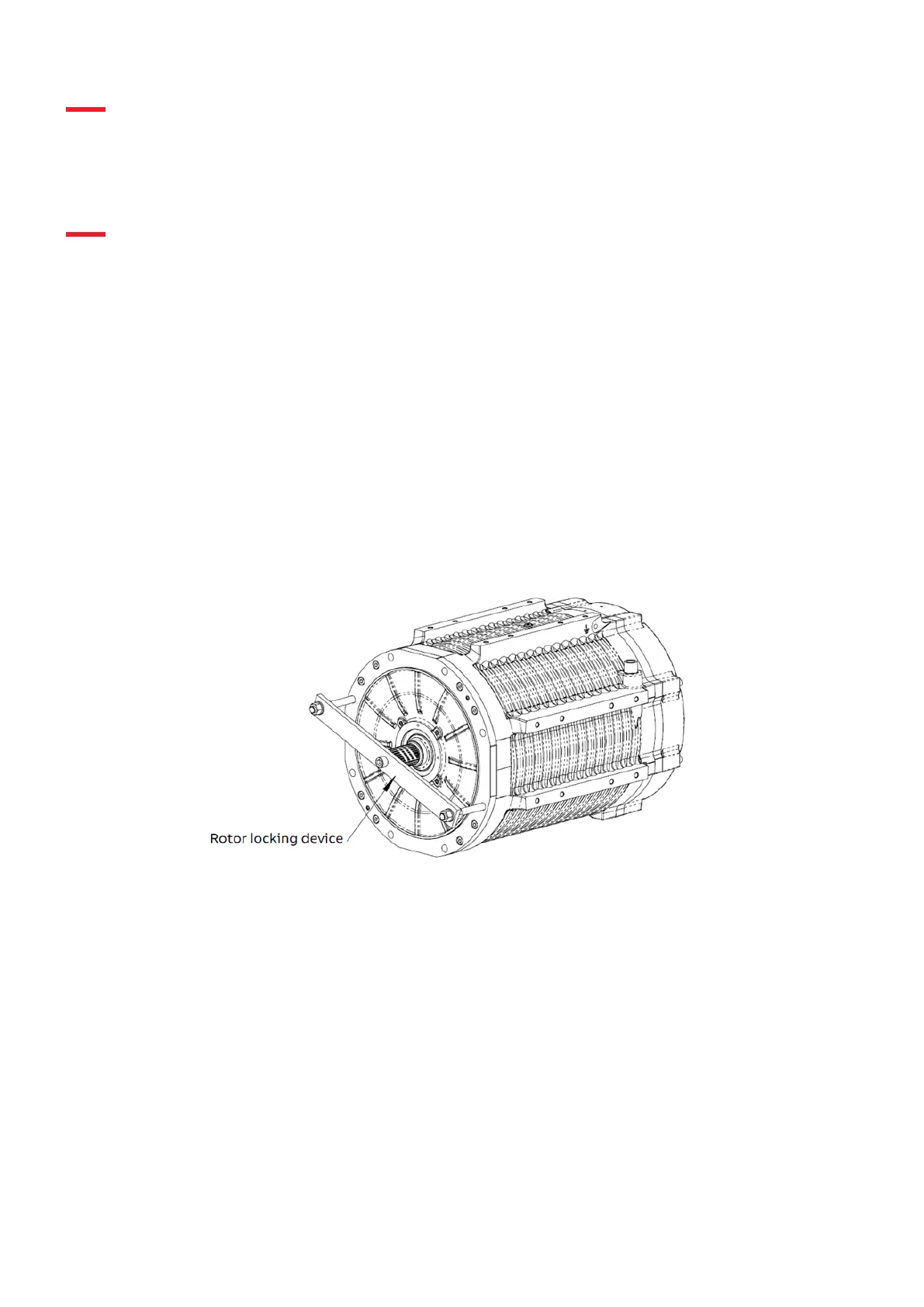

NOTE: When the motor is delivered, the shaft is fixed and secured by a rotor locking device at the

D-end of the shaft. The rotor locking device should not be removed as long as the motor

remains in storage. Remove the rotor locking device prior to installation of the motor.

Figure 3. Rotor shaft locking during transportation and storage.

3.1.2. Inspection of delivery

Unpacking should be done carefully in order to avoid damage. The delivery should be checked against the

packing list.

NOTE: When the traction motor arrives at its destination, make sure to check the traction motor in

order to determine possible transport damage as quickly as possible. Any damage during

delivery or deviations from packing list should be entered in a report and the transport

company contacted.

If the traction motor has suffered damage during transport or installation, this must be rectified before

commissioning.

Loading...

Loading...