MOTORS FOR HEAVY ELECTRICAL VEHICLES

24

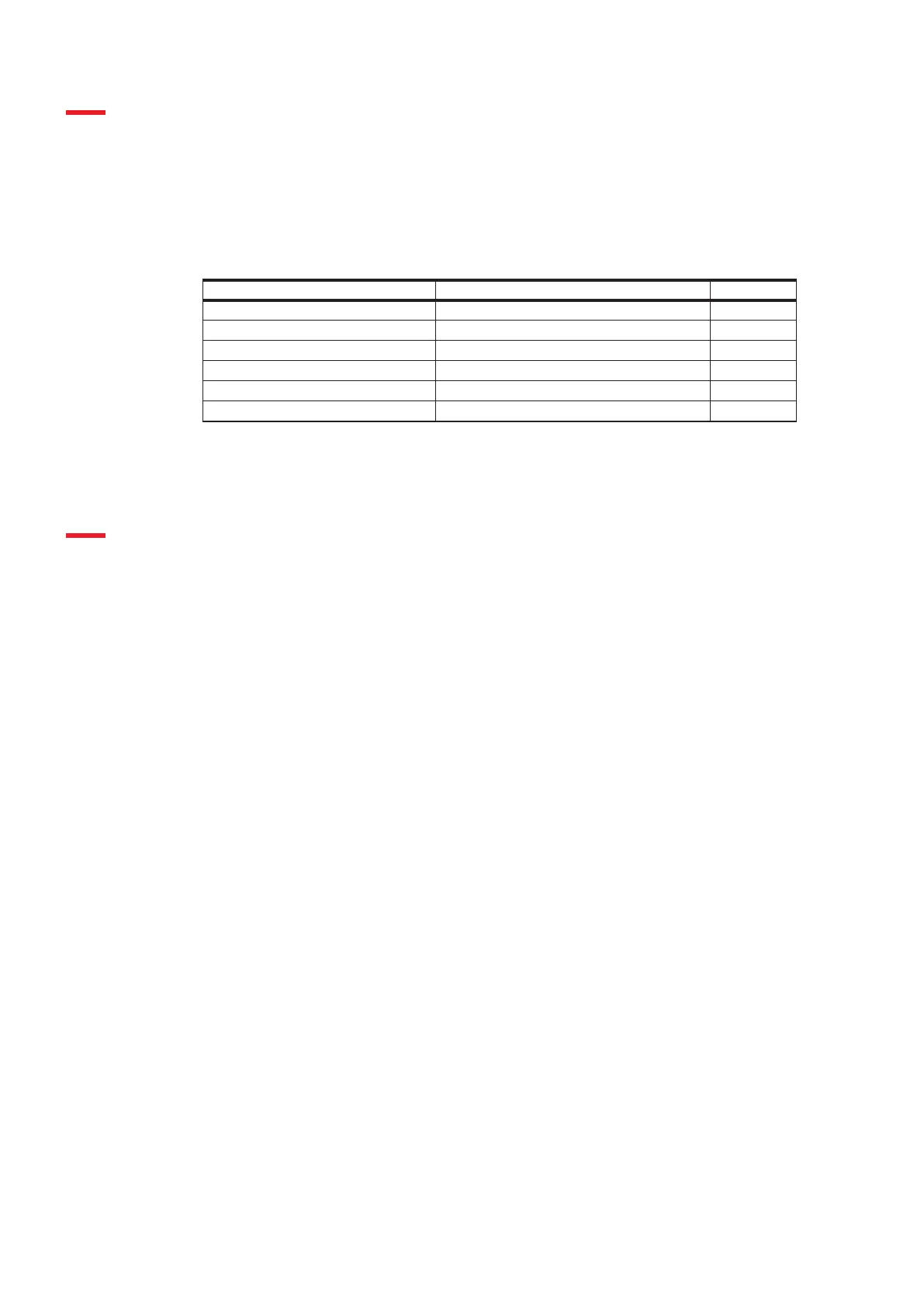

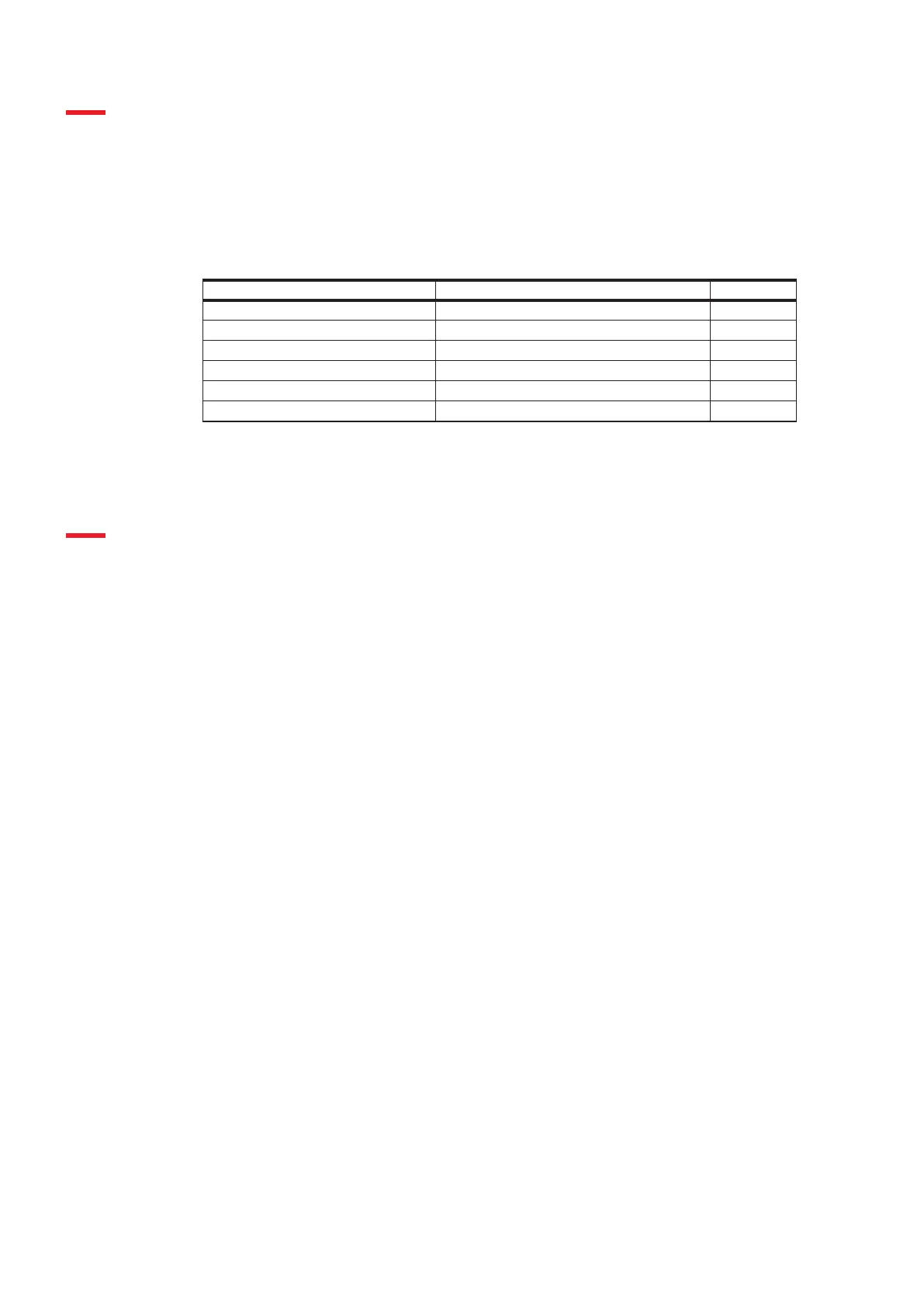

6.1. Inspection and maintenance intervals

NOTE: The need for maintenance can vary depending on local conditions.

It is important to follow the recommendations to ensure a fully working motor.

Action Interval Chapter

Visual inspection Weekly

Detailed visual inspection

Bearings

External shaft seal

Shaft spline

External cleaning

Table 5. Inspection and maintenance intervals

6.2. Inspection and maintenance actions

6.2.1. Visual inspection

The purpose of the visual inspection is to do a quick check to see whether problems are beginning to

develop before they can cause failures and unscheduled maintenance breaks.

The visual inspection shall include the following areas:

1. Listen for any abnormal noise or increased vibrations

2. Verify that the liquid cooling system connections for inlet and outlet are free from dust or any parts

that block the flow. If required, clean the inlet and outlet areas.

Check that there are no fluid leakages. The pressure drop may not exceed 1 bar.

3. Verify that the temperature sensors in the stator winding are functioning properly

NOTE: If there is a potential safety risk, inform management and take necessary emergency

measures.

6.2.2. Detailed visual inspection

The purpose of the detailed visual inspection is to do a check to see whether problems are beginning to

develop before they can cause failures and unscheduled maintenance breaks.

The detailed visual inspection shall include the following areas:

1. The points described in 6.2.1.

Loading...

Loading...