MOTORS FOR HEAVY ELECTRICAL VEHICLES

18

4.3.2.2. Bottom mounted

The motor may be turned and mounted with the 12 o’clock side mount interface facing downward.

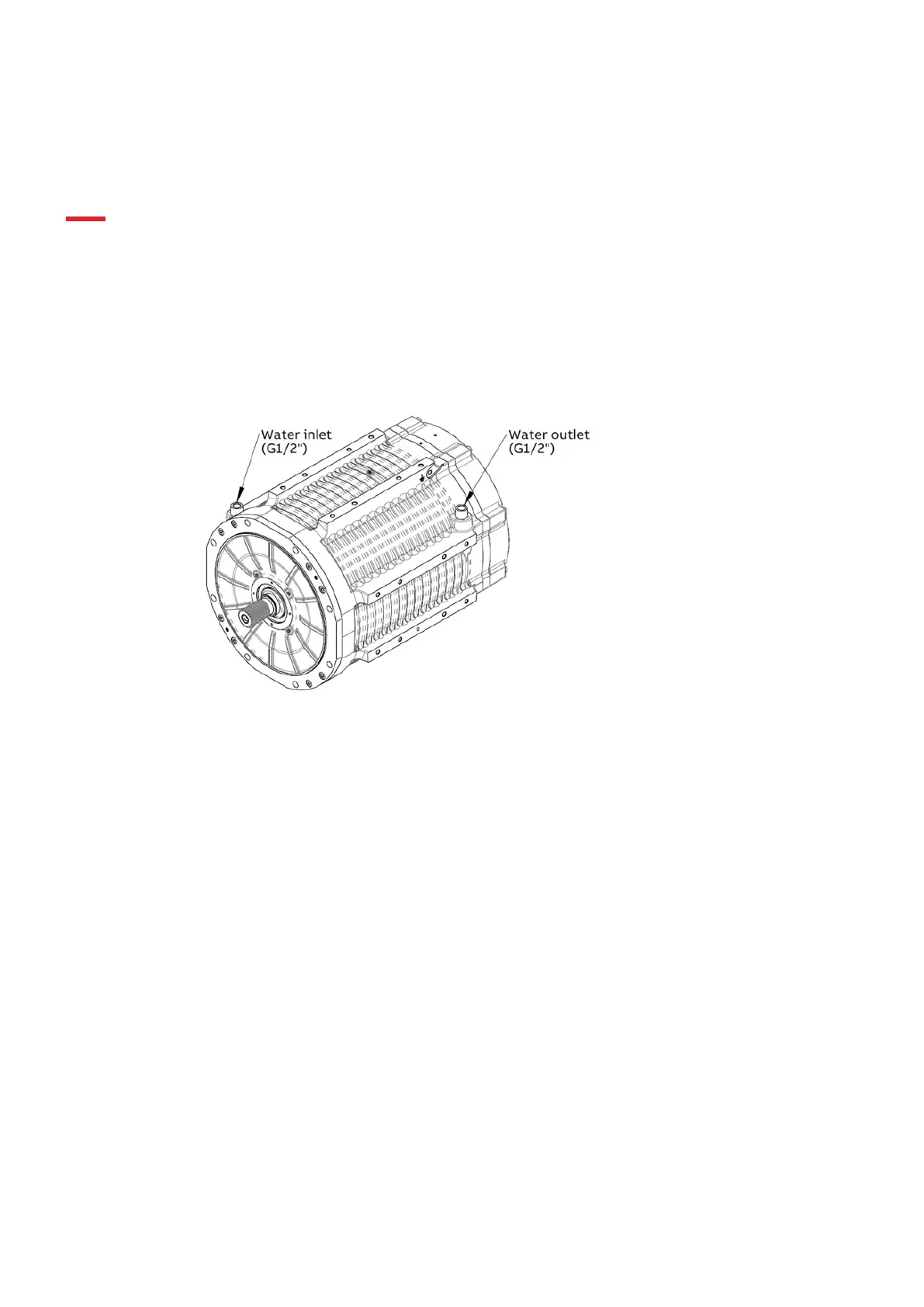

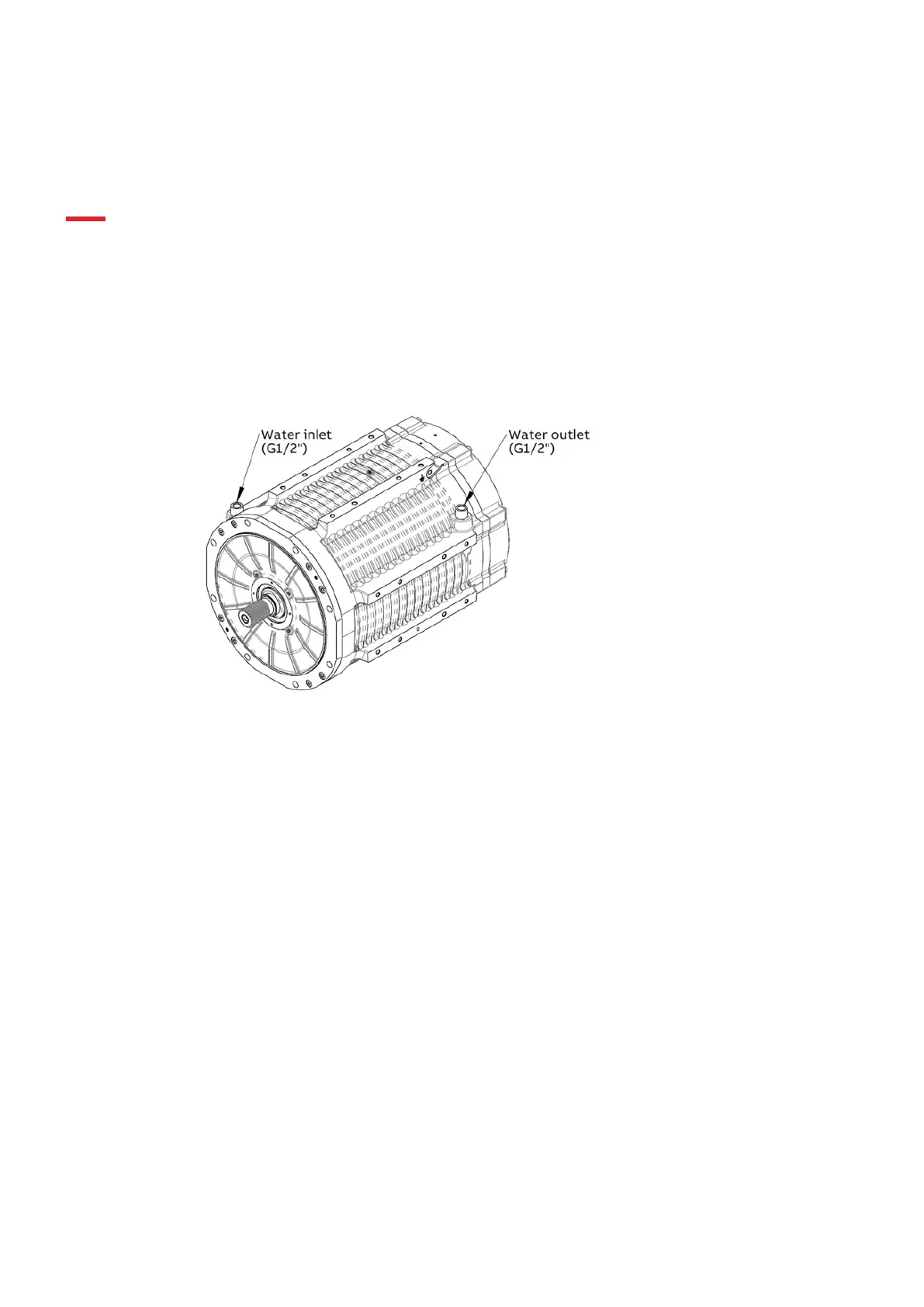

4.4. Liquid cooling system installation

Remove the protective covers from the cooling inlet and outlet threads (internal ISO 228 - G 1/2") and

install the mating cooling connectors, see Figure 8. To prevent leakage, it is advisable to use a mating

cooling connector equipped with an O-ring seal and apply thread sealant (Loctite 577 or similar) in the

internal thread.

Figure 8. Position of liquid cooling inlet and outlet.

Recommended coolants are ethylene glycol based such as Antifrogen® N from Clariant or propylene glycol

based mixed with water. The motor design is intended for a mixture of 50% / 50%. Max allowed pressure

is 4 bar at inlet connection.

NOTE: Coolants might be a toxic compound. Use correct personal safety equipment and avoid

exposure to the coolant.

NOTE: Ensure that the specified data on the separate rating plate, see Figure 3, is fulfilled before

operating the motor.

Loading...

Loading...