Manual for Induction Motors and Generators

62 - Maintenance

3BFP 000 050 R0101 REV E

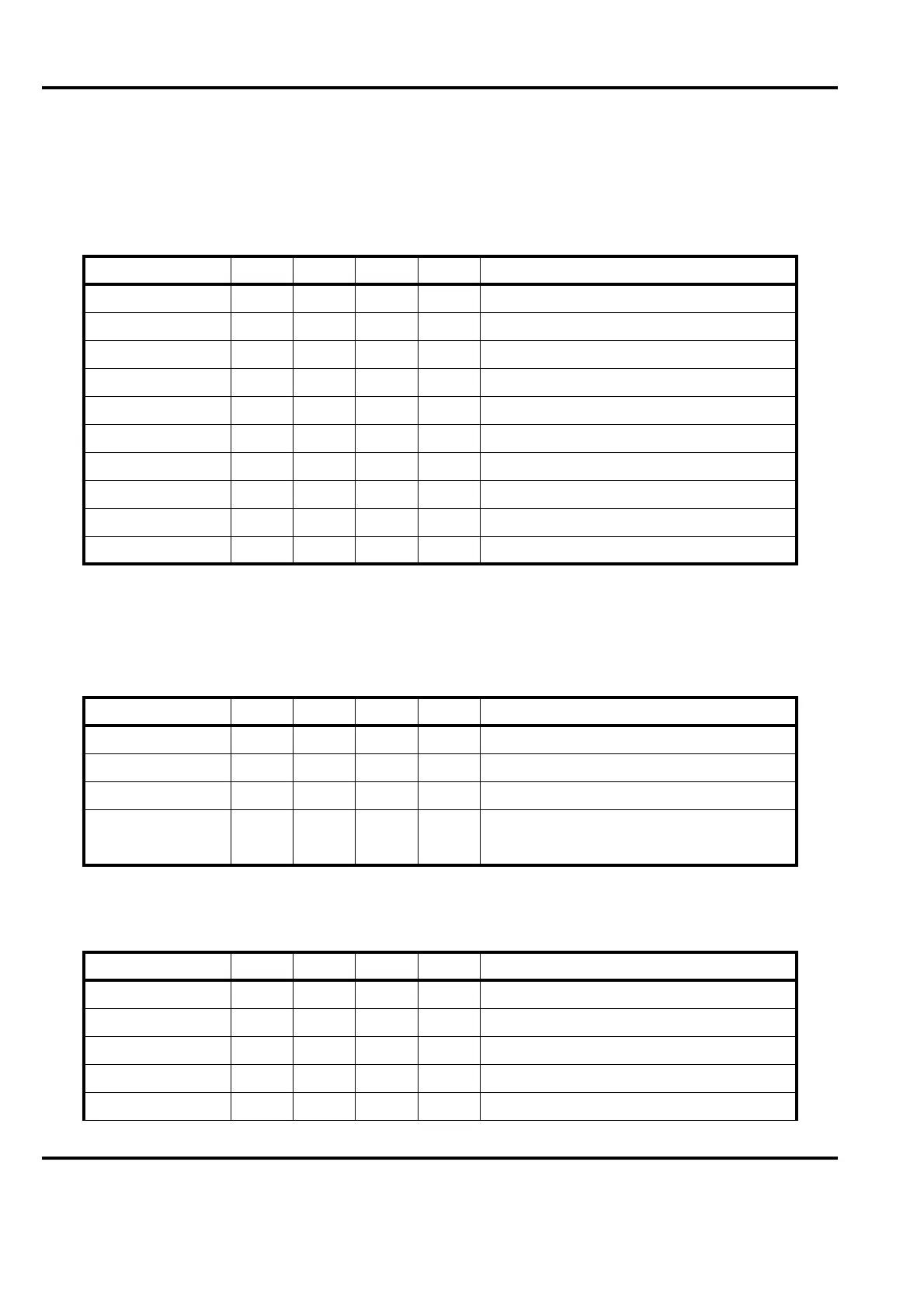

***Following table for rotor type: Slip rings

7.3.1.5 Slip ring unit

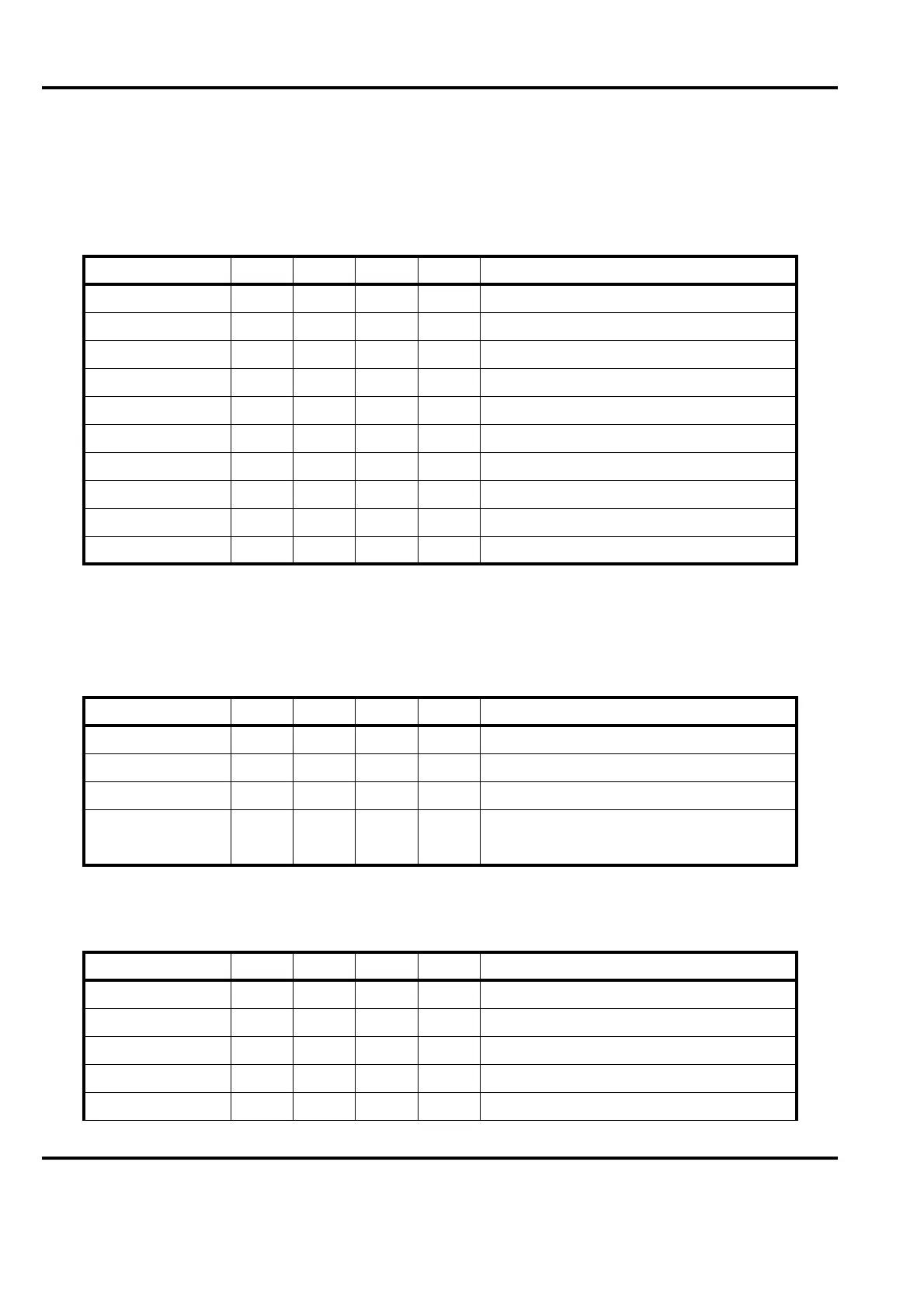

7.3.1.6 Lubrication system and bearings

***Following table for bearing type: Rolling bearing

***Following table for bearing type: Sleeve bearing

Maintenance object L1 L2 L3 L4 Check / Test

Assembly V V / C V / C V / C Mounting, insulation

Brush holders v V / T V / T V / T Alignment

Brushes V V / T V / T V / T Arching, clearance

Slip ring cabling V V V V Wear, arching

Slip rings V / T V / T V / T V / T Wear, roundness, patina

Brush gear V V / T V / T V / T Insulation resistance

Pt-100 elements V V / T V / T V / T Resistance

Anticondensation heaters V V / T V / T V / T Operation, insulation resistance

Encoders V V V / t V / T Operation, general condition, alignment

Auxiliary terminal boxes V V / T V / T V / T General condition, terminals, wiring condition

Maintenance object L1 L2 L3 L4 Check / Test

Bearing during operation T T T / R T / R General condition, extra noise, vibration

Waste grease V V / C V / C V / C Condition, purging

Re-greasing V V / R V / R V / R According to bearing plate

Seals V V / D V / D V / D Leakage

Bearing insulation V / C V / C V / C / T V / C / T Endshield cleanliness, insulation resistance

Maintenance object L1 L2 L3 L4 Check / Test

Bearing assembly V V / T V / T V / T Fixing, general condition

Bearing shells V V V / T / D V / T / D General condition, wear

Seals and gaskets V V V / T / D V / T / D Leakage

Bearing insulation V V / T V / T / D V / T / D Condition, insulation resistance

Lubrication piping V V V / T D V / T / D Leakage, operation

Loading...

Loading...