Installation

Preliminary operations.

•

Clean the insulating parts with clean dry cloths

•

Check that the top and bottom terminals are

clean and free of any deformation caused by

shocks received during transport or storage

Installation of VSC in 800 mm width switchgear.

This withdrawable VSC vacuum contactors are

preset for insertion in the corresponding 800 mm

width switchgear. Insertion and racking-out of

the contactor must be gradual to avoid any shocks

which could deform the mechanical interlocks. If

the operations are prevented, do not force the

interlocks and check that the operating sequence

is correct. Please also refer to the technical

documentation of the switchgear for the vacuum

contactor installation operations.

CAUTION!

The racking-in and racking-out

operations must always be carried out

with the contactor open.

The VSC is preset for use in 800mm width UniGear

and similar designed panels. For switchgear

racking-in/racking-out, fully insert the lever in

the appropriate seat and work it clockwise for

racking-in, and anti-clockwise for racking-out,

until the limit switch positions are reached.

The racking-in/-out must be carried out gradually

to avoid shocks which may deform the mechanical

interlocks and the limit switches.

If operations are prevented or difficult, do not

force them and check that the operating

sequence is correct.

When the contactor has reached the isolated for

test/isolated position, it can be considered

racked into the switchgear.

For the contactor installation operations, also refer

to the technical documentation of the

above-mentioned switchgear.

Putting into service

General procedures:

All the operations regarding putting into

service must be carried out by ABB

personnel or personnel who are suitably

qualified and have in-depth knowledge of

the apparatus and installation. If the

operations are prevented, do not force the

mechanical interlocks, but check that the

operation sequence is correct.

Before putting the contactors into service, carry

out the following operations:

•

Check the tightness of the power connections

on the contactor terminals

•

Check that the value of the supply voltage for

the auxiliary circuits is within 85% and 110% of

the rated voltage of the electrical devices

•

Check that no foreign body, such as packaging,

has got into the moving parts

•

Check that air circulation at the contactor

installation site is adequate so that there is no

danger of overheating

•

Carry out the checks indicated in the Table 1

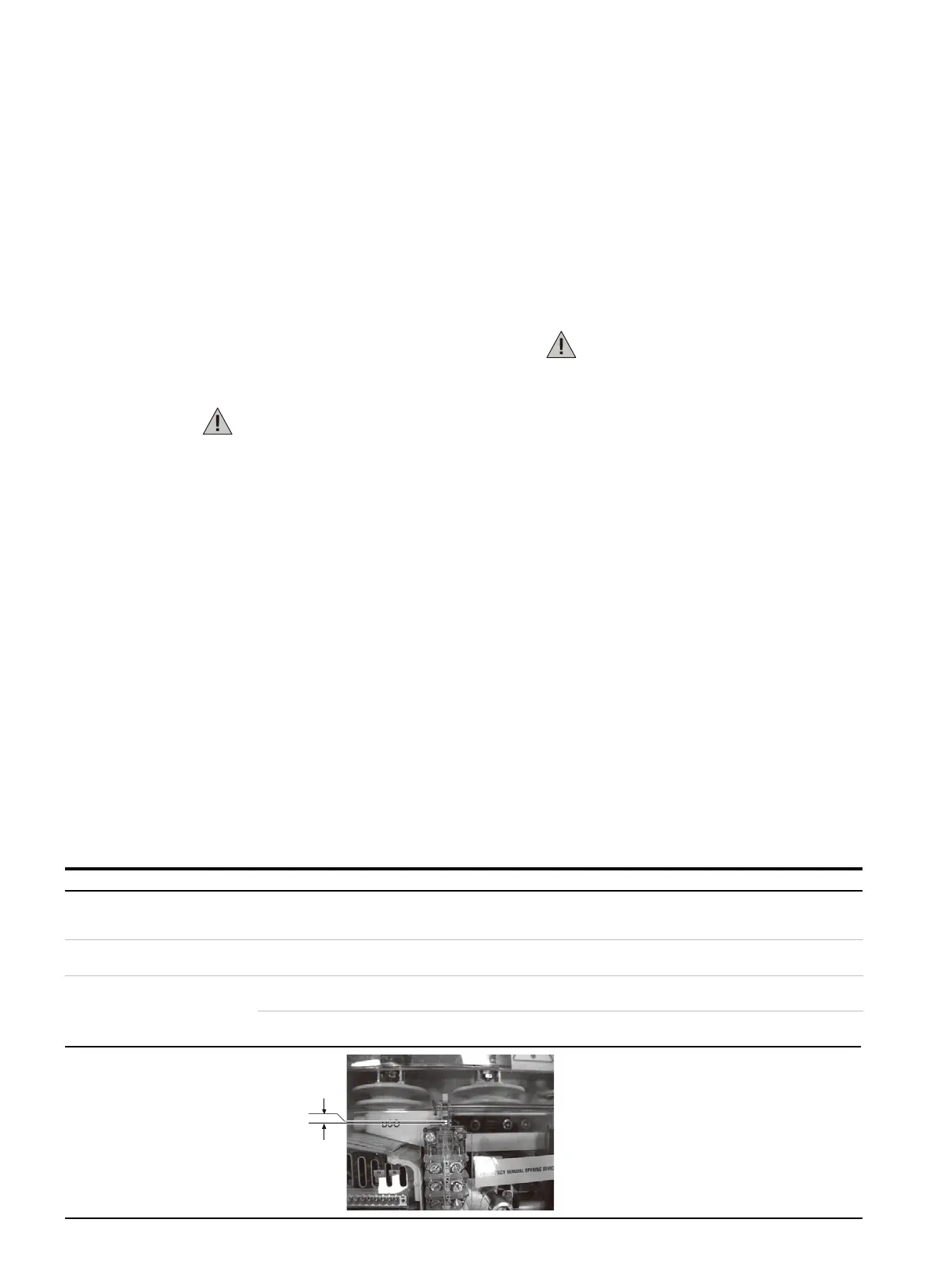

9Specific VSC instruction

0,5 mm

—

Table. 1

Item inspected Procedure Positive check

1. Insulation resistance

The insulation resistance should be at

least 50 Mohm.

Carry out a few closing and opening operations of the

contactor.

Operations and signals normal.

3. Auxiliary circuits

Operations and signals normal.

Tighten the fixing screws.

Medium voltage circuit use lower letter, with and not Width With

a 2500 V megger, measure the insulation resistance between

the phases and the exposed conductive part of the circuit.

Check that the connections to the control circuits are

correct: proceed with the relative power supply.

With the contactor open, check that the thickness between

the body of the contact and the stem is 0.5 mm.

2. Drive open/closed indicator,

operation counter (if provided)

Loading...

Loading...