Kinetix 5700 Dual-axis Inverters 3

Rockwell Automation Publication 2198-PC002D-EN-P - November 2017

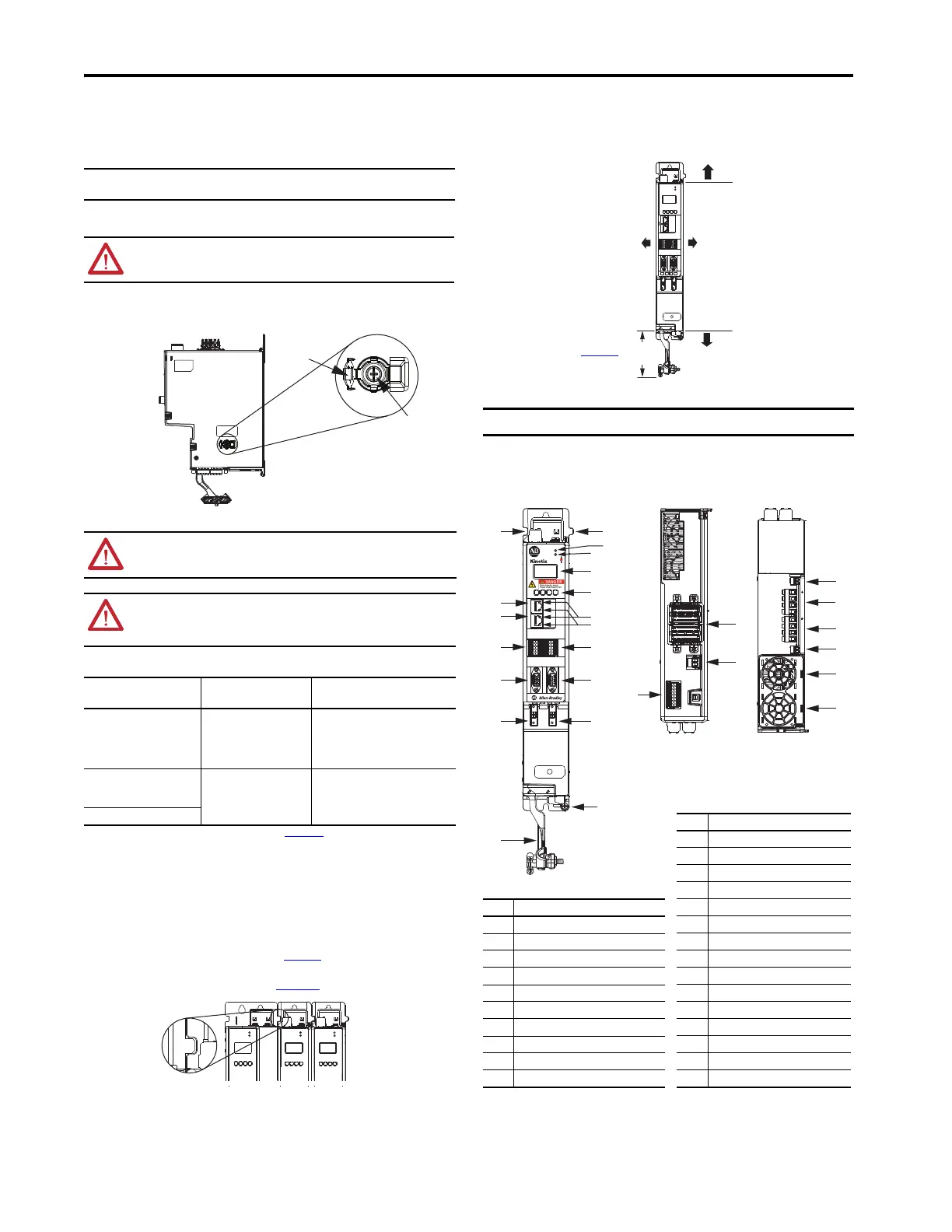

Ground Screw Installation

Included with the drive module connector set is a ground screw. Install the ground screw for grounded (wye)

power configurations. Do not install the ground screw when using ungrounded, corner-grounded, or

impedance-grounded power, the Bulletin 8720MC regenerative power supply, or any active converter.

We recommend that you install the ground screw when the drive is removed from the panel and placed on its

side on a solid surface equipped as a grounded static-safe workstation.

To access the ground screw on dual-axis inverters, open the small plastic door on the right side of the module.

Install the Ground Screw

Ground Screw Configurations

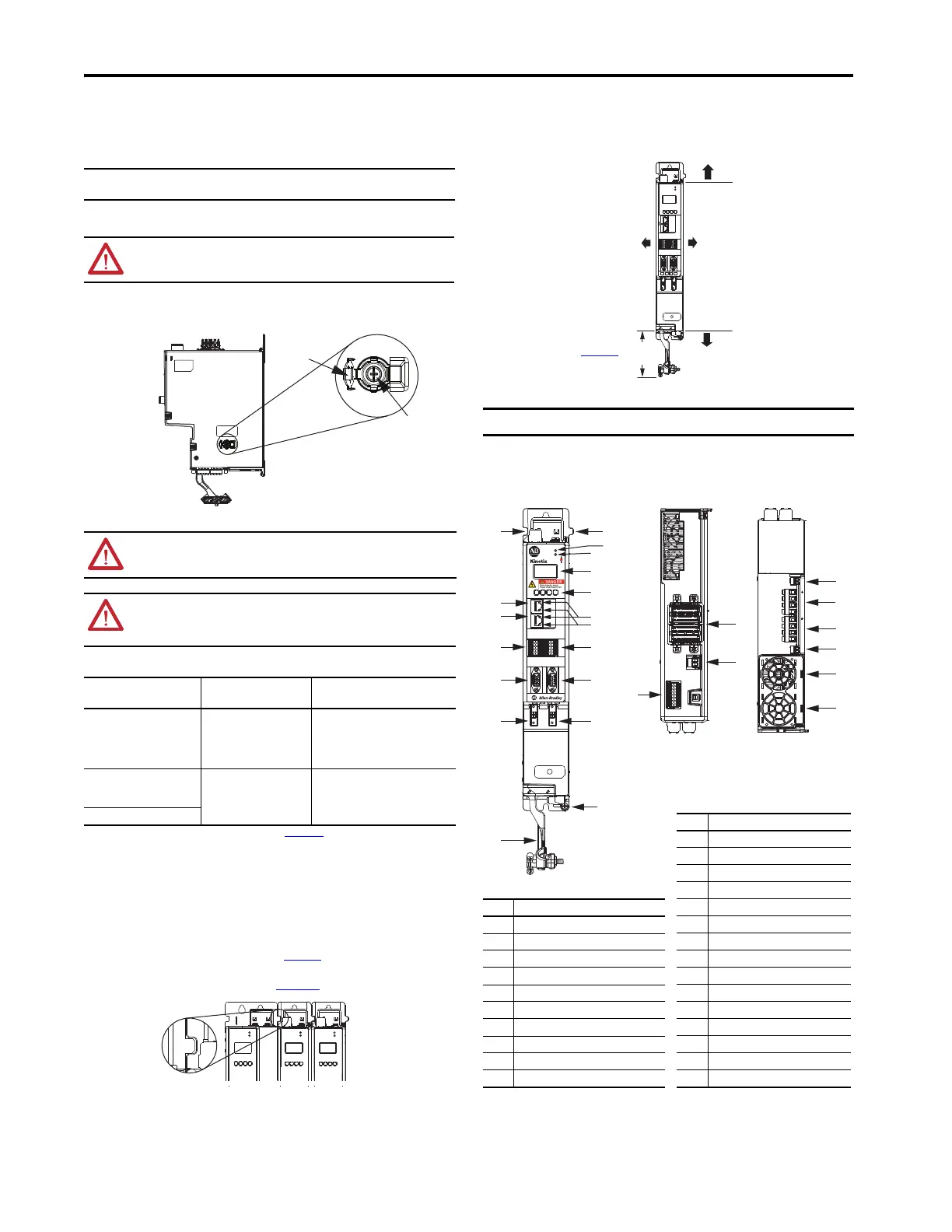

Mount the Dual-axis Inverter

Observe these clearance requirements when mounting the dual-axis inverter:

• Additional clearance is required for cables and wires or the shared-bus connection system connected to the

top of the drive.

• Additional clearance is required if other devices are installed above and/or below the drive and have

clearance requirements of their own.

• Additional clearance left and right of the drive is required when mounted adjacent to noise sensitive

equipment or clean wire ways.

• The recommended minimum cabinet depth is 300 mm (11.81 in.).

Refer to the Kinetix Servo Drives Technical Data, publication KNX-TD003

, for Kinetix 5700 drive dimensions.

The Kinetix 5700 drive system must be spaced by aligning the zero-stack tab and cutout. For hole patterns, refer

to the Kinetix 5700 Servo Drives User Manual, publication 2198-UM002

.

Mount the Kinetix 5700 servo drives to the cabinet subpanel with M5 (#10-32) steel bolts torqued to 4.0 N•m

(35.4 lb•in), max.

Minimum Clearance Requirements

Connector Data

Use this illustration to identify the dual-axis inverter features and indicators.

Dual-axis Inverters Features and Indicators (2198-D006-ERSx inverter is shown)

IMPORTANT

If you have grounded-wye power distribution and 2198-Pxxx DC-bus power supply, install the

ground screw. EMC performance can be affected if the ground screw is not installed.

ATTENTION: When the ground screw is not installed, the risk of equipment damage exists

because the unit no longer maintains line-to-neutral voltage protection.

ATTENTION: To avoid personal injury, the ground screw access door must be kept closed when

power is applied. If power is applied, and then removed, wait at least 5 minutes for the DC-bus

voltage to dissipate, and verify that no DC-bus voltage exists before accessing the ground screw.

ATTENTION: Risk of equipment damage exists. The drive ground configuration must be

accurately determined. Install the ground screw for grounded power configurations. Do not

install the screw for ungrounded, corner-grounded, and impedance-grounded power, or when an

active converter supplies the DC-bus voltage.

Ground Configuration

(1)

(1) Refer to the Kinetix 5700 Servo Drives User Manual, publication 2198-UM002, for example power configurations.

Ground Screw

Configuration

Benefits of Configuration

Grounded (wye) Installed

• UL and EMC compliance

• Reduced electrical noise

• Most stable operation

• Reduced voltage stress on

components and motor bearings

• AC-fed ungrounded

• Corner grounded

• Impedance grounded

Not installed (default setting)

• Helps avoid severe equipment

damage when ground fault occurs

• Reduced leakage current

DC-bus from active converter

Install the ground screw for grounded power

configurations. Do not install the ground screw for

ungrounded, corner-grounded, and impedance-grounded

power or grounded systems with active power supplies

(screw not installed is the default setting).

Ground Screw

Access Door

Ground Screw

Ground Screw

2198-Dxxx-ERSx

Dual-axis Inverter

(side view)

Zero-stack Tab and

Cutout Aligned

Shared-bus connection system

is not shown for clarity.

IMPORTANT Mount the drive in an upright position as shown. Do not mount the drive on its side.

1

I/O-A

6

10

1

I/O-B

6

5

10

UFB-A

UFB-B

D+

D-

D+

D-

MF-A

MF-B

MOD

NET

2

1

5

93 mm

(3.7 in.)

Clearance right of the

drive is not required.

Clearance left of the

drive is not required.

2198-Dxxx-ERSx

Dual-axis Inverter

(front view)

100 mm (3.94 in.) clearance

below drive for airflow and

installation.

40 mm (1.57 in.) clearance above

drive for airflow and installation.

Refer to the Kinetix Servo Drives

Technical Data, publication KNX-TD003

,

for Kinetix 5700 drive dimensions.

22

12

7

9

17

10

14

13

16

2

11

11

8

20

19

25

15

24

21

3

4

6

5

1

23

25

18

1

I/O-A

6

10

1

I/O-B

6

5

10

UFB-A

UFB-B

D+

D-

D+

D-

MF-A

MF-B

2

1

5

DC+

DC–

24V–

24V+

SB+/NC

S1A

SCA

S2A

SB-

S1B

SCB

S2B

1

8

9

16

W-B V-B U-B

MBRK-A

– +

W-A V-A U-A

MBRK-B

– +

MOD–

NET–

5700

2198-Dxxx-ERSx

Dual-axis Inverter

(top view)

2198-Dxxx-ERSx

Dual-axis Inverter

(bottom view)

2198-Dxxx-ERSx

Dual-axis Inverter

(front view)

Item Description

1 Motor cable clamp

2Ground lug

3 Motor feedback (MF) connector - A

4 Motor feedback (MF) connector - B

5 Universal feedback (UFB) connector - A

6 Universal feedback (UFB) connector - B

7 Digital inputs (IOD) connector - A

8 Digital inputs (IOD) connector - B

9 Ethernet (PORT1) RJ45 connector

10 Ethernet (PORT2) RJ45 connector

Item Description

11 Zero-stack mounting tab/cutout

12 Module status indicator

13 Network status indicator

14 LCD display

15 Navigation push buttons

16 Link speed status indicators

17 Link/Activity status indicators

18 Safe torque-off (STO) connector

19 DC bus (DC) connector

20 24V control input power (CP) connector

21 Motor brake (BC) connector - A

22 Motor power (MP) connector - A

23 Motor power (MP) connector - B

24 Motor brake (BC) connector - B

25 Cooling fan

Loading...

Loading...