FOR MODELS: JGW, JGR AND JGJ SECTION 5 - MAINTENANCE

PAGE 5 - 20 1/01

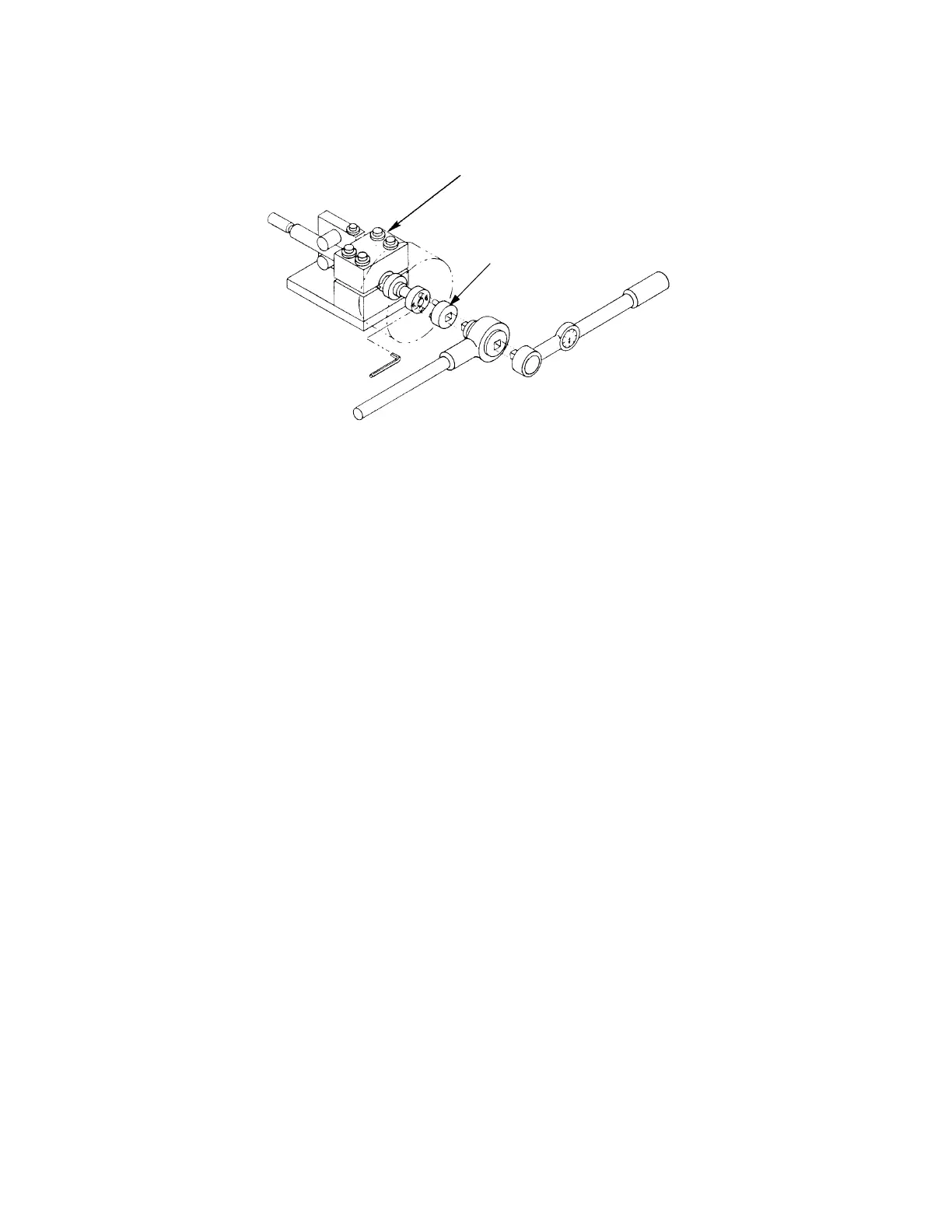

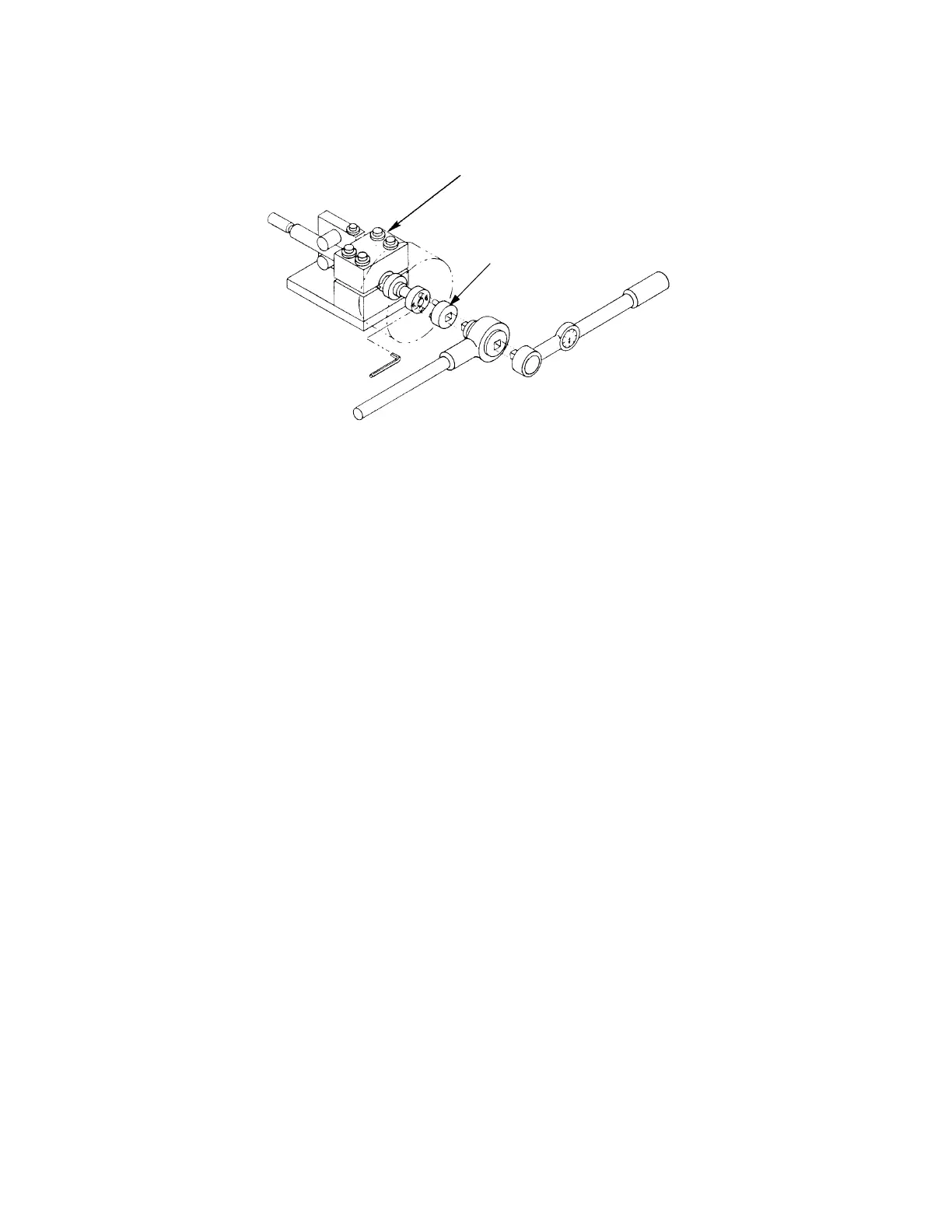

1. Clamp the piston and rod assembly in the special Clamping Fixture (D-0961),

using the bushing for a 1-1/2” rod size (see Figure 5-12:). Tighten the four 12-

point cap screws to prevent the rod from turning. The fixture will properly hold

the piston rod to prevent damage to the parts and promote safety during disas-

sembly and reassembly. The Clamping Fixture must be securely bolted down to

prevent it from turning with the piston rod. It should be at a convenient height of

approximately three feet or 0.9 meters. Remove the setscrews from the piston

nut. Although the piston nut has been staked to lock the setscrews, they can be

forced out, by turning with an Allen wrench, past the small lip that has been

formed.

2. Remove piston nut using piston nut spanner (see Figure 7-1: on page 7-3).

NOTE: A SMALL AMOUNT OF GAS PRESSURE CAN BUILD UP WITHIN THE PISTON

DURING OPERATION. THIS WILL VENT WHEN THE PISTON NUT IS LOOS-

ENED.

3. After the piston nut has been removed, the piston and collar will slip off the end

of the rod.

Reassembly

1. Clean all piston and rod assembly parts thoroughly. Be sure piston is internally

clean and dry.

2. Inspect parts for nicks, burrs or scratches and dress surfaces with a fine grit

stone as required.

3. Inspect the piston rod threads and collar shoulder. Threads should be clean and

free of burrs. Install the collar and nut onto the piston rod to verify that the inside

diameter firs and rotates freely. Run the piston nut down by hand until the rod

threads protrude to verify freedom of thread engagement. Remove nut and col-

lar.

FIGURE 5-12: PISTON AND ROD CLAMPING FIXTURE

Part Num-

ber

D-0961

Spanner bolts

onto piston nut

Loading...

Loading...