FOR MODELS: JGW, JGR AND JGJ SECTION 5 - MAINTENANCE

1/01 PAGE 5 - 23

under the piston as the piston is moved throughout its stroke. Re-measure vertical run out

and compare to acceptable limits in the table above. The horizontal readings, taken without

the use of feelers are to be used for acceptance. Copy Table 5-5 and record calculations

and readings.

If readings are not within acceptable limits after replacing worn parts and correcting any pip-

ing misalignment, the piston rod assembly should be replaced.

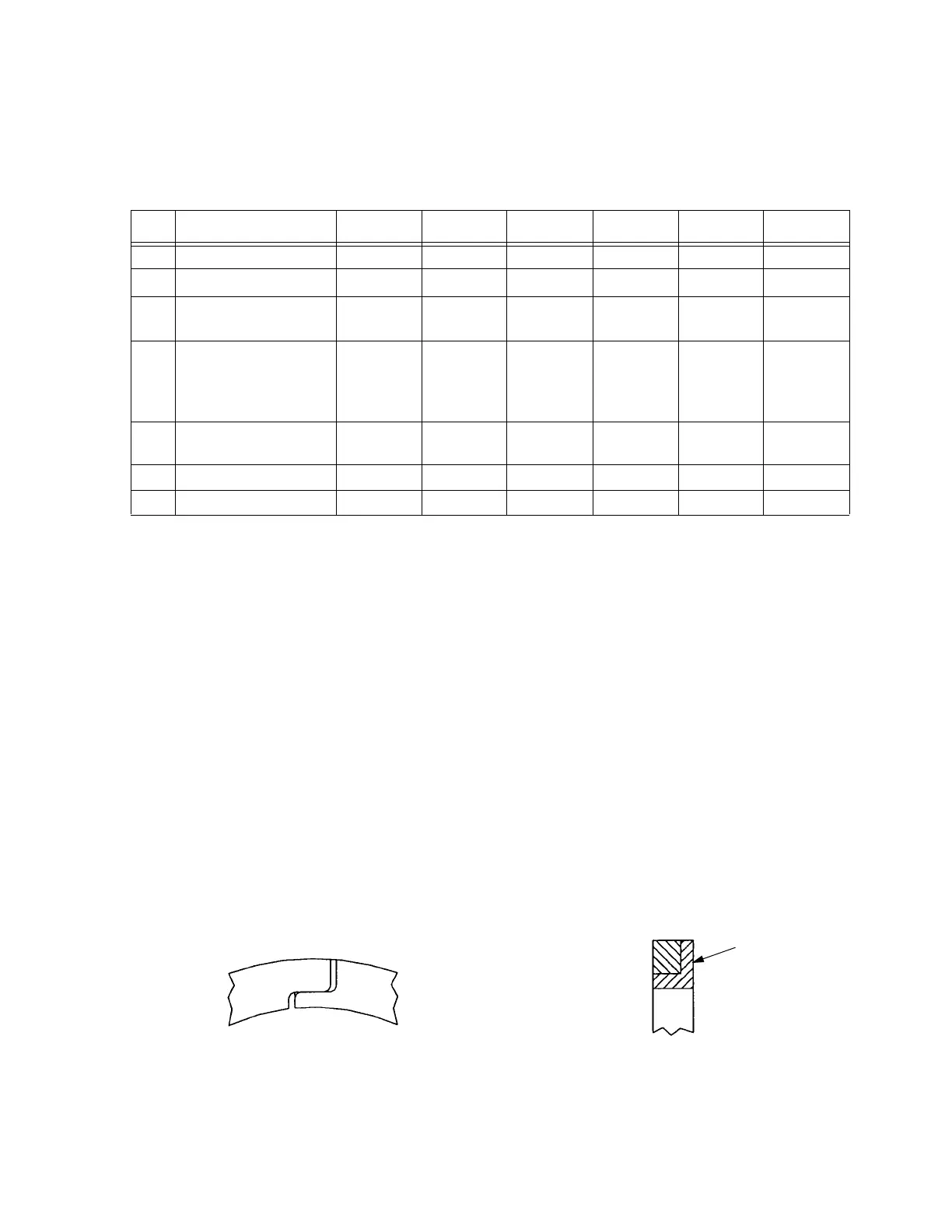

Piston Rings

All JGW, JGR and JGJ cylinders use one-piece angle cut filled Teflon piston rings, excepting

tandem cylinders which use stepped seal-joint piston rings and very small cylinders which

use two-piece rings. Seal-joint rings are available for double acting cylinders. Refer to Figure

5-13:.

Seal-joint piston rings are directional and must be installed properly.

To utilize the seal-joint rings in double acting cylinders, in place of angle cut rings, contact

Ariel for new part numbers.

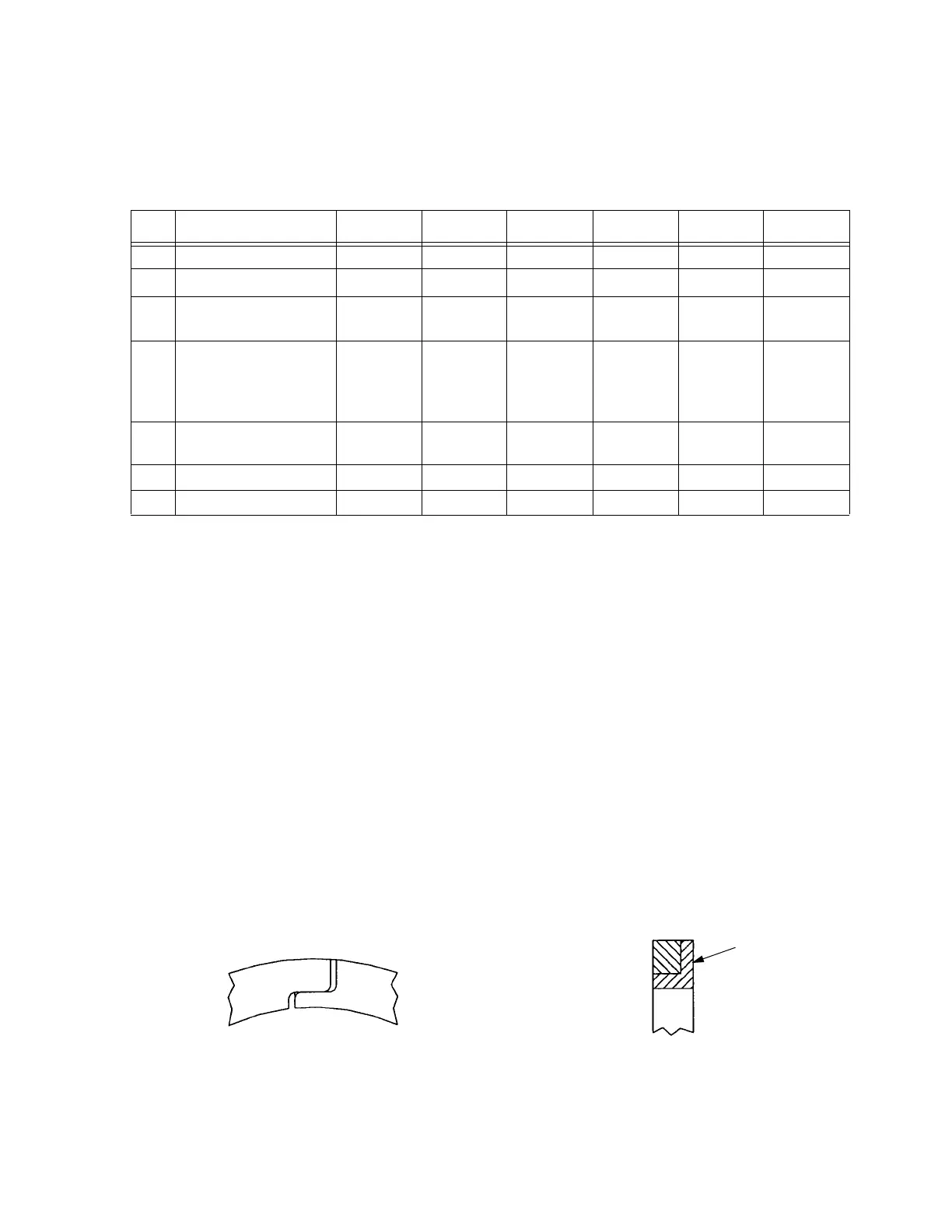

TABLE 5-5: FEELER THICKNESS TO CORRECT FOR PISTON WEIGHT

LINETHROW NUMBER:123456

1 Top Feeler Clearance

2

Line 1 (

)2)

3

JGJ

Line 2 - 0.003”

(-0.08 mm)

- 0.003”

(-0.08 mm)

- 0.003”

(-0.08 mm)

- 0.003”

(-0.08 mm)

- 0.003”

(-0.08 mm)

- 0.003”

(-0.08 mm)

- 0.003”

(-0.08 mm)

4

JGW

&

JGR

Line 2 - 0.004”

(-0.10 mm)

- 0.004”

(-0.10 mm)

- 0.004”

(-0.10 mm)

- 0.004”

(-0.10 mm)

- 0.004”

(-0.10 mm)

- 0.004”

(-0.10 mm)

- 0.004”

(-0.10 mm)

4 Bottom Feeler

Thickness

5Vertical~Piston @ CE000000

6 Vertical~Piston @ HE

FIGURE 5-13: SEAL-JOINT RINGS

Stamped Side

Toward Pressure

Loading...

Loading...