14

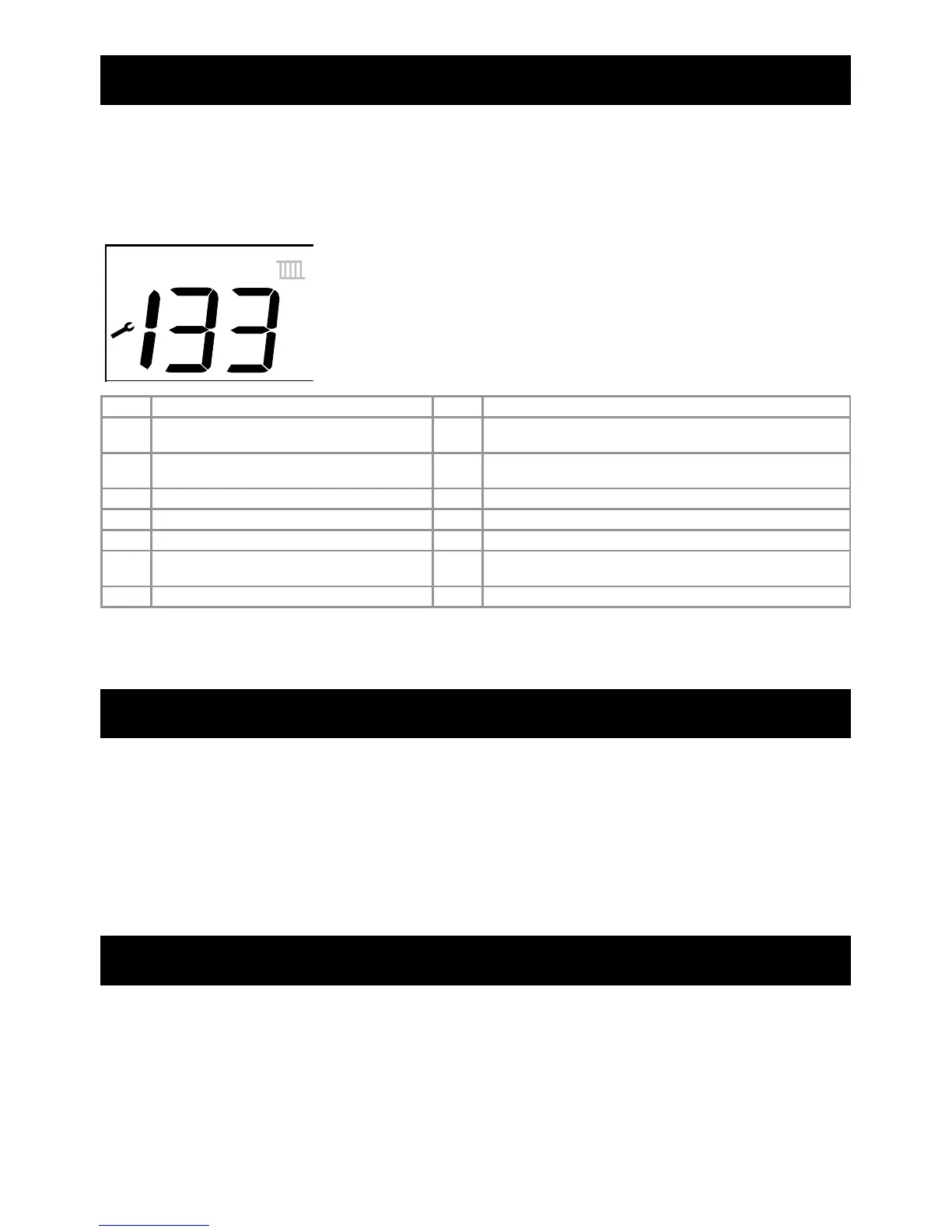

7 Error codes

In the event of a failure (this is indicated by a number code on the display) you

can try to eliminate the failure by pressing the Reset button. If the failure persists,

please contact your installer as soon as possible and tell him the number code.

There are also messages with a number code that

constitute no failures. These messages will cancel

themselves over time (*) or they need intervention.

Operating the reset button has no effect then.

10 Outside sensor error 111 Maximum temperature exceeded

20 Flow sensor error 117 Pressure too high (> 3 bar) or pump pressure increase too high

(iC & iS-Range only)

40 Return sensor error 118 Pressure too low (< 1 bar) or pump pressure increase too low

(no pump detection) (iC & iS-Range only)

50 DHW sensor error (iC-Range only) 119 Link on X2 position 4 and 5 missing

61 Bus communication error 129 Fan error (fan does not start up)

78 Water pressure out of range 133 No ame after 5 ignition attempts

105* Venting program active when power turned on or

interrupted (runs approx. 7 mins.)

151 Fan error (speed control is not achieved or is out of range) or

control unit defective

110 Safety temperature exceeded 154 Flow temperature increases to fast, return > ow

If leaks occur in the installation, please contact your installer.

8 Maintenance

Conclude a maintenance agreement with your installer in order to have the

installation periodically checked and adjusted.

The cover of the boiler consists of metal and plastic parts, which can be cleaned

with a normal (non-aggressive) cleansing agent.

9 Warranty

For the warranty conditions, see the Warranty Card that has been supplied with

the boiler.

Loading...

Loading...