2920 1454 00

19

Instruction book

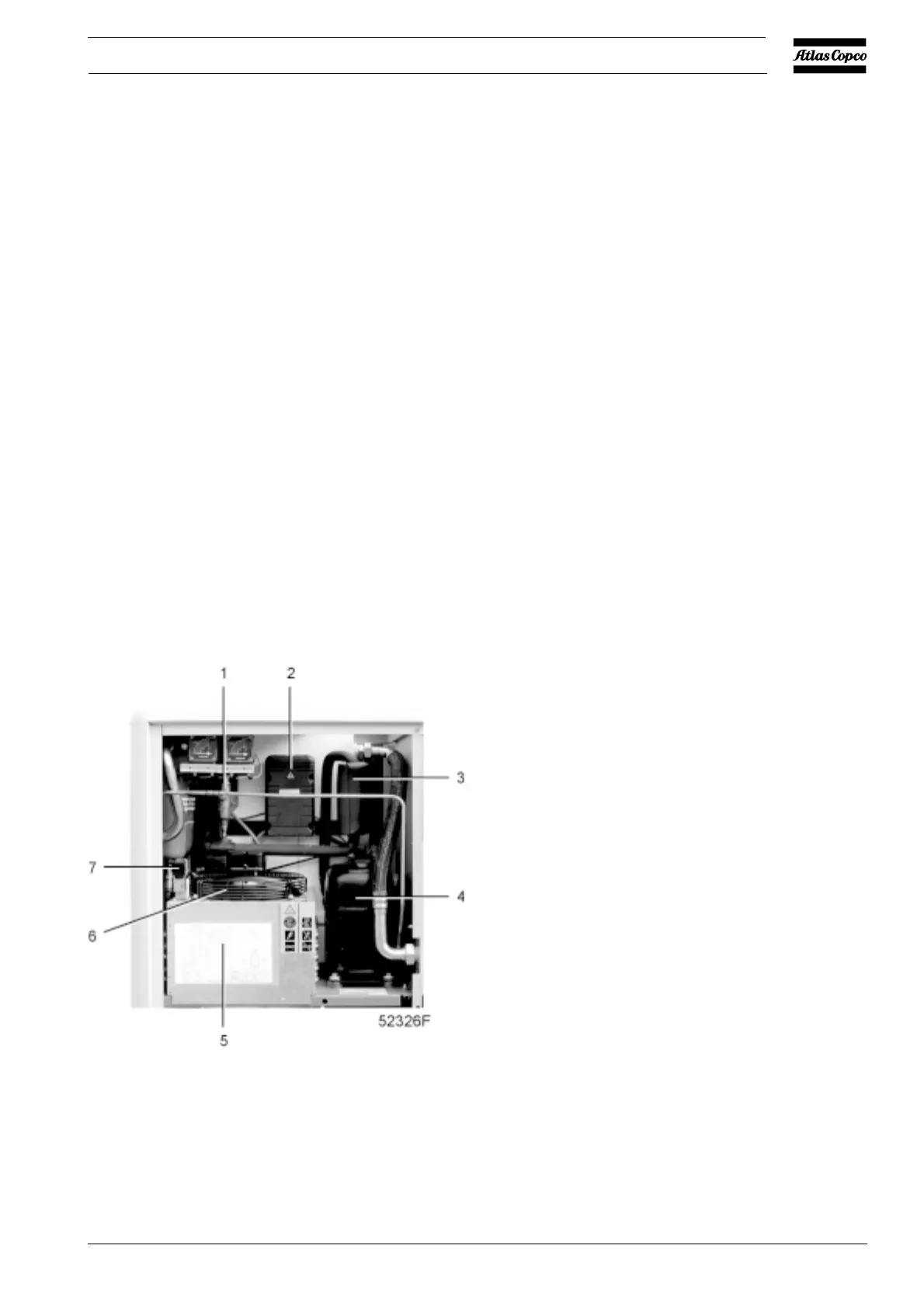

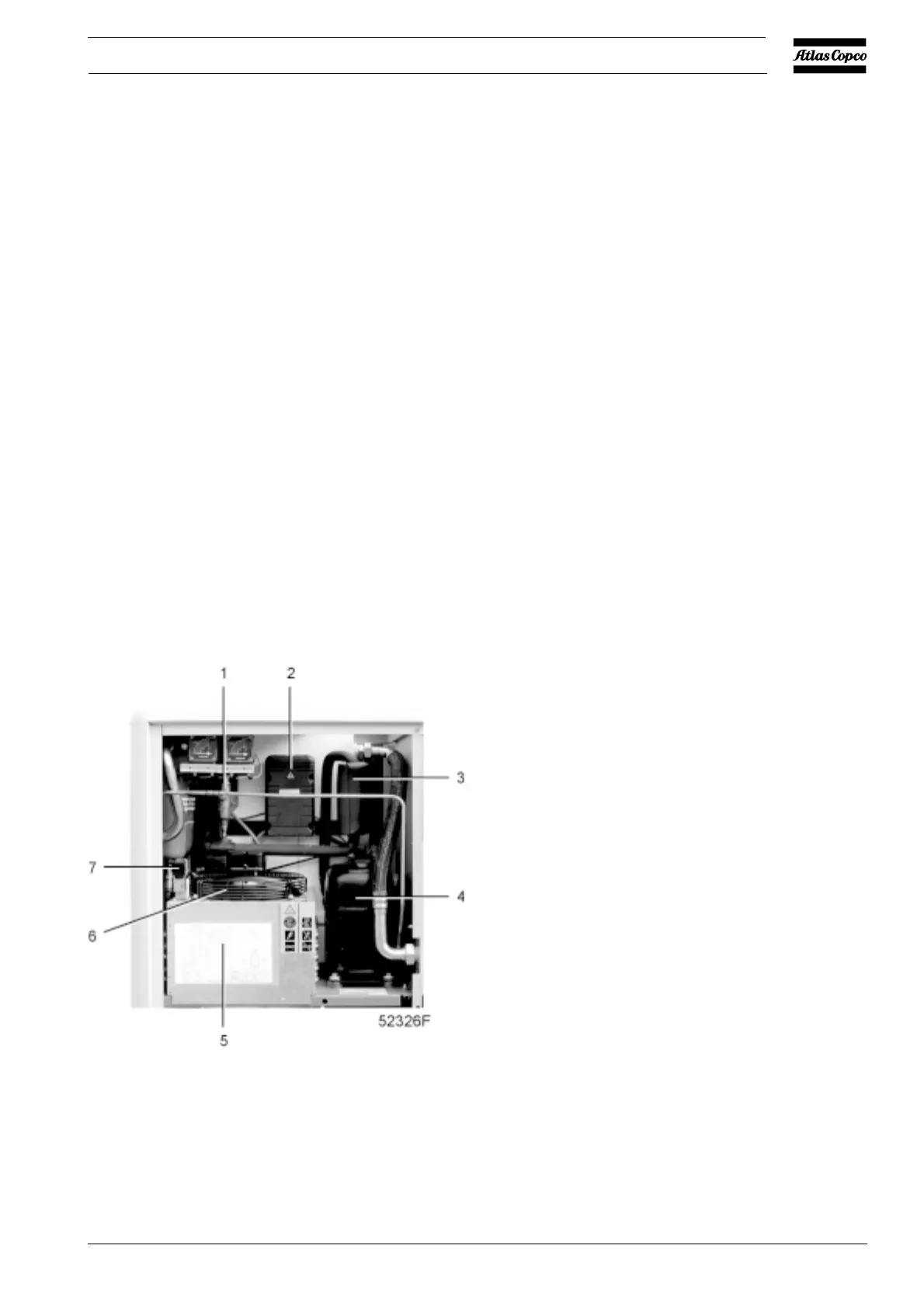

1 Hot gas by-pass valve

2 Cubicle

3 Accumulator

4 Refrigerant compressor

5 Condenser

6 Condenser fan

7 Fan control switch

Fig. 3.5 Air dryer

3. The display (12) will show a service message if a service

plan interval has been exceeded or if a service level for a

monitored component has been exceeded. Carry out the

service actions of the indicated plans or replace the

component and reset the relevant timer.

Warning Before carrying out any maintenance, repair or

adjustment, stop the compressor, press the

emergency stop button (S3-Fig. 1.1), close the

air outlet valve and open valves (1 and 4-Fig.

1.5). Wait until the compressor is depressurized.

Switch off the voltage.

Notes:

- Whenever a shut-down, shut-down warning, service

request, sensor error or fan motor overload message is

displayed, the free spaces on the display between the

function keys (3) are filled with blinking indicators (**).

- When more than one message needs to be displayed (e.g.

both warning and service), the messages are continuously

displayed for 3 seconds each.

4. Regularly press the ¯ key (1-Fig. 1.7) on the main screen

to call up information about the actual compressor

condition:

- the maximum pressure

- the status of controlling the compressor (local or

remote)

- the status of the compressor start/stop timer (on or off)

3)

- the actual speed

- the loaded hours

- the motor starts

- the module hours

- the accumulated m³

- the outlet pressure

- the pressure difference over the oil separator

- the compressor element outlet temperature

- the dewpoint temperature 4)

- the status of the fan motor overload protection (normal

or not)

3.5 Stopping (Fig. 1.7)

1. Press stop button O (10). LED (9) goes out. The

compressor stops and the message Programmed stop

appears on the screen. Five seconds later, the message

changes from Programmed stop to Compressor stopped.

2. To stop the compressor in case of emergency, press the

emergency stop button (S3-Fig. 1.1).

3. Close the air outlet valve and switch off the voltage.

4. Open condensate drain valves (1 and 4-Fig. 1.5).

3.6 Taking out of operation

At the end of the life cycle of the compressor, proceed as

follows:

1. Stop the compressor and close the air outlet valve.

2. Switch off the voltage and disconnect the compressor

from the mains.

3. Wait until the compressor has depressurized. Unscrew

plug (3-Fig. 3.1) only one turn to permit any pressure in

the system to escape. Open drain valves (1 and 4-Fig.

1.5).

4. Shut off and depressurize the part of the air net which is

connected to the outlet valve. Disconnect the

compressor air outlet pipe from the air net.

5. Drain the oil and condensate circuits.

6. Disconnect the compressor condensate piping from the

condensate drain net.

Loading...

Loading...