Instruction book

5 Servicing and adjustment procedures

Warning

Release the pressure from the compressor before starting repair or maintenance works. Switch off the

voltage and isolate the compressor from the mains.

5.1 Unloader or check valve

It is recommended to replace the unloader or check valve as indicated in section 4.2.

Dirt, condensate, coke formation and oxidation influence the proper operation of the valve. Depending on

the environmental and working conditions (ambient temperature, working pressure, load cycle, oil type),

the local Sales company may overrule the maintenance schedule (consult Atlas Copco).

5.2 Valves

A faulty valve must be replaced immediately. A faulty valve can be discovered as stated in section 6,

points 1 and 4. Consult Atlas Copco.

It is highly recommended to replace the valve discs, O-rings and gaskets if disassembling the cylinder

heads.

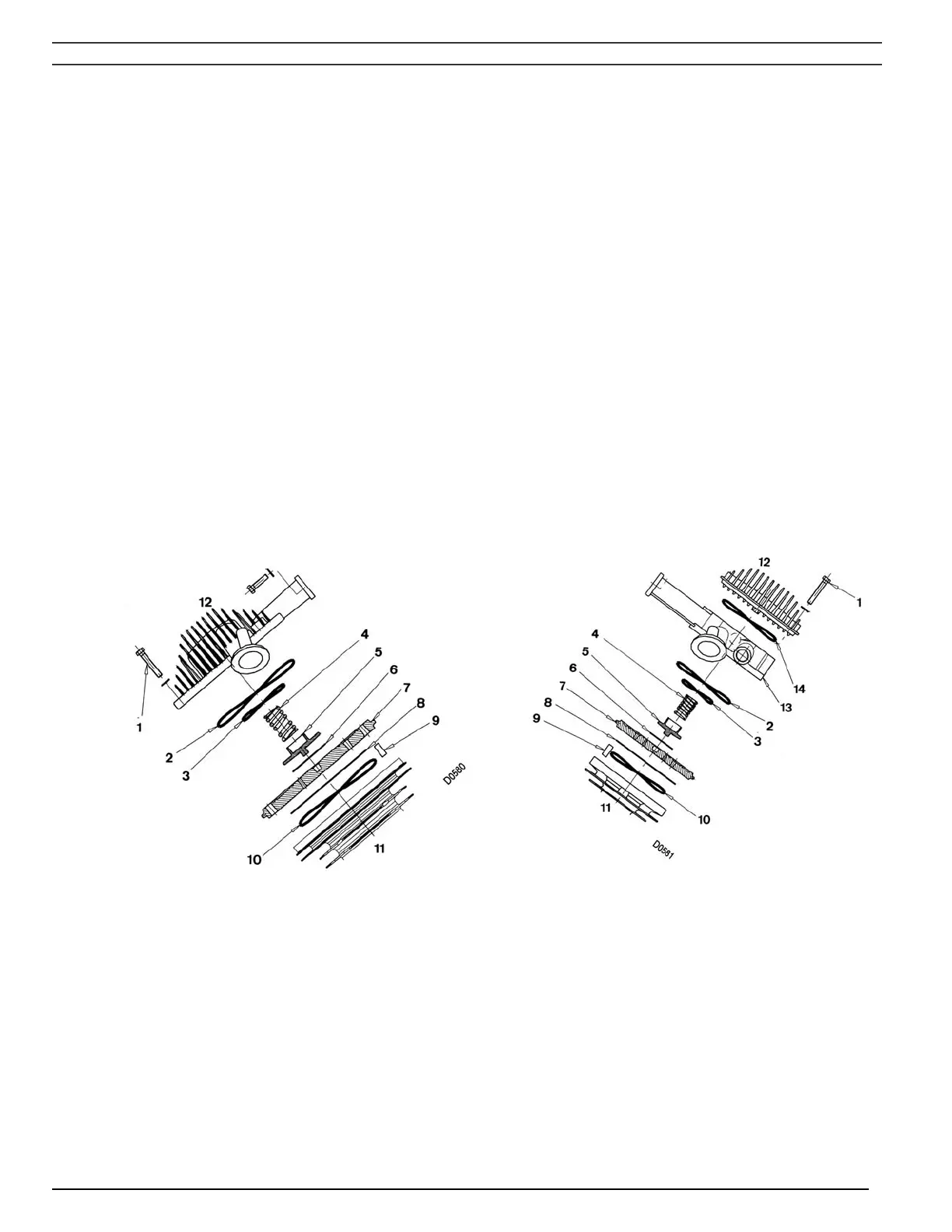

Fig. 5.1 LE2 up to -7, LE10 50 Hz, LF2 up to -5

Low-pressure side of LE10 60 Hz, LE15, -20,

LF7, -10, LT15/60, LT15-30, LT15, -20, LT20-

30, LT2 up to -10

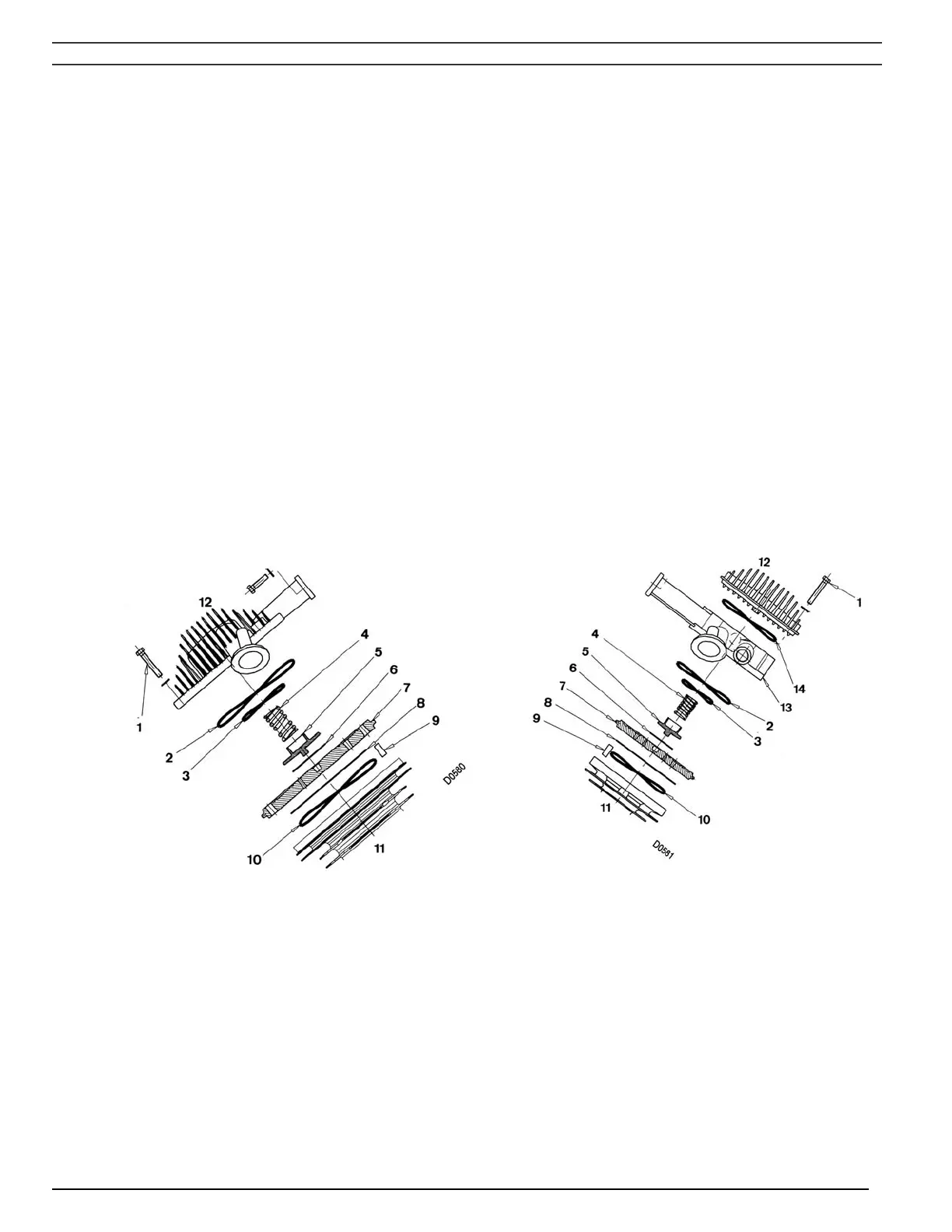

Fig. 5.2 High-pressure side of LF7, LT15/60, LT15-

30, LT15, LT2 up to -10

2920 1585 00 - 53 -

Loading...

Loading...