Instruction Manual

2954 9020 00 15

4. Maintenance

(1) More frequently when operating in a dusty environment. Evacuate

dust from the airfilter valve daily.

(2) A Service Bulletin (ASB) dealing elaborately with batteries and

due care is available on request.

4.2 Engine maintenance

Refer to the engine’s operator manual for full maintenance, includ-

ing instructions for changing the oil and cooling water and replac-

ing the fuel, oil and air filters.

4.3 (*)Measuring the alternator insulation

resistance

A 500 V megger is required to measure the alternator insulation re-

sistance.

If the N-terminal is connected to the earthing system, it must be dis-

connected from the earth terminal. Disconnect the AVR. Discon-

nect the radio interference suppressor.

Connect the megger between the earth terminal and terminal L1

and generate a voltage of 500 V. The scale must indicate a resis-

tance of at least 5 M

Ω.

Refer to the alternator operating and maintenance instructions for

more details.

Before carrying out any maintenance activity, check that the start switch is in position O and that no electrical power is

present on the terminals.

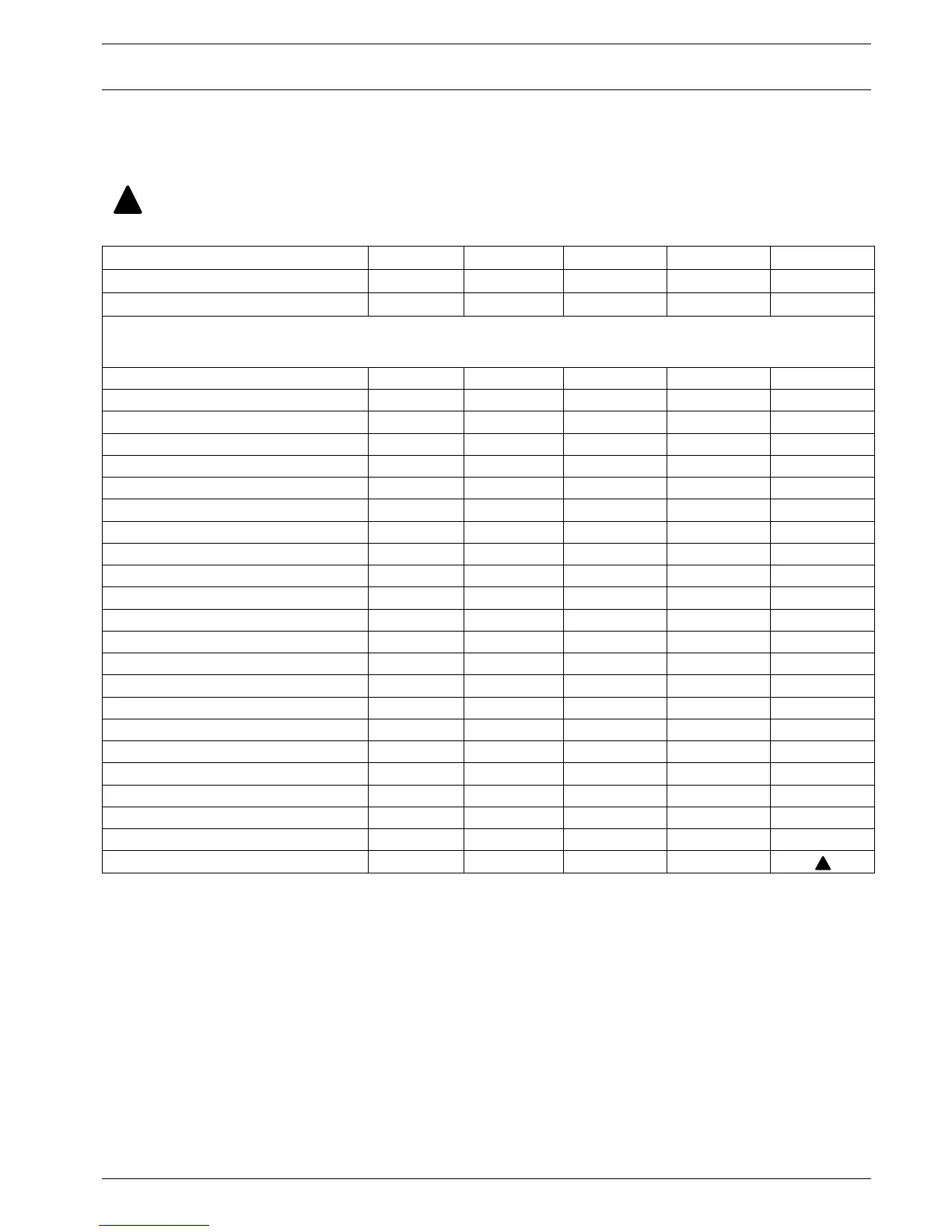

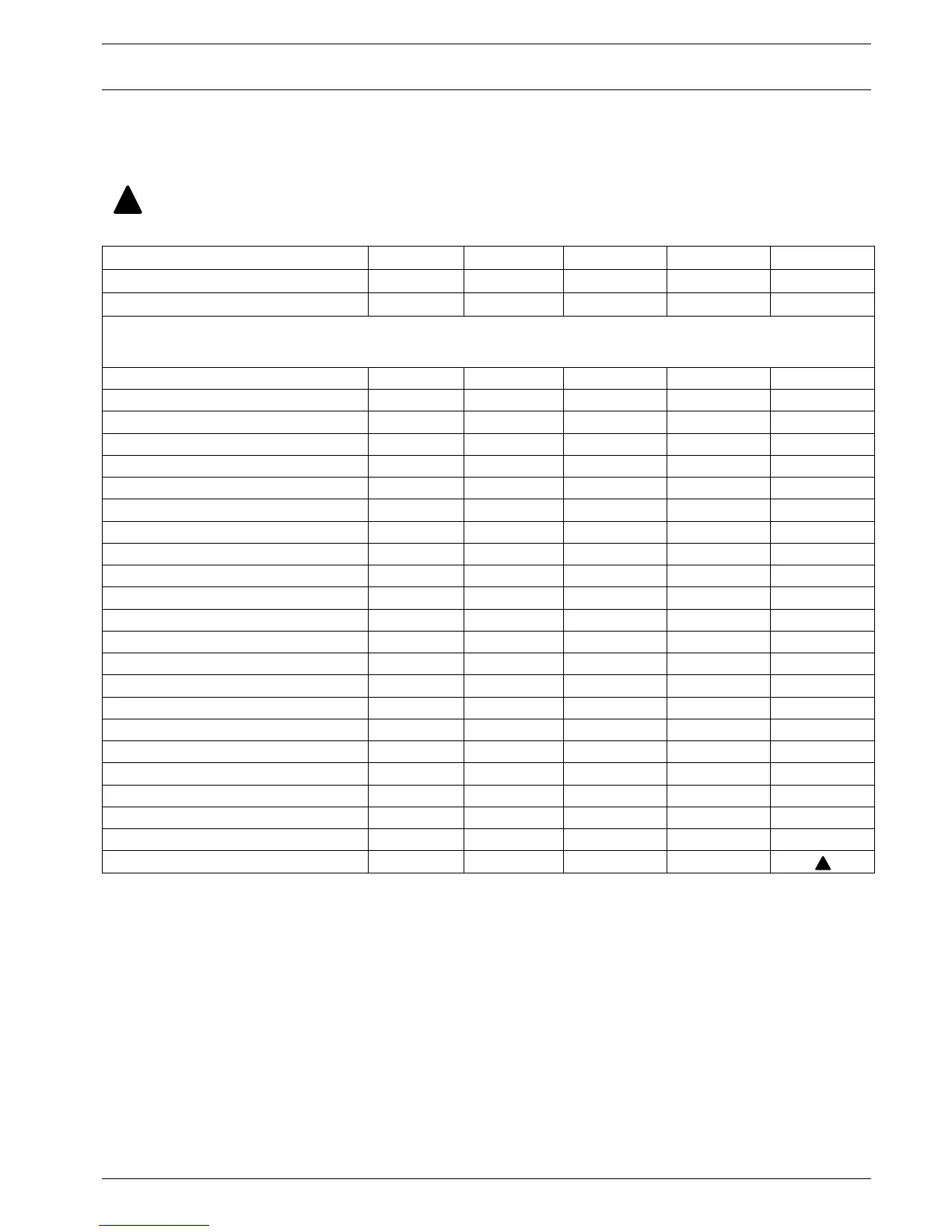

4.1 Maintenance schedule

Daily Initial Small Normal Yearly

50 hours 250 hours 500 hours 2000 hours

SERVICE PAK - With unit

2912 6038 00 2912 6039 00 2912 6040 00

For the most important subassemblies, Atlas Copco has developed service kits that combine all wear parts. These service kits offer you

the benefits of genuine parts, save on administration costs and are offered at reduced price, compared to the loose components. Refer to

the parts list for more information on the contents of the service kits.

Coolant level Check Check Check Check Check

Tension and condition of drive belt(s) Check Check Check Replace

Radiator and intercooler fins Check/Clean Check/Clean Check/Clean Check/Clean

Fuel pre-filter/Water separator Check/Drain Check/Drain Check/Drain Check/Drain Check/Drain

Fuel filter element Replace Replace Replace Replace

Fuel injectors Check

Oil level in sump Check Check Check Check Check

Oil pressure on gauge Check Check Check Check Check

Lubrication oil Change Change Change Change

Oil filter(s) Replace Replace Replace Replace

Air cleaner and dust bowl Clean Clean Clean Clean

Air filter element (1) Clean Replace Replace

Safety cartridge Replace

Valve clearance Check/adjust Check/adjust Check/adjust Check/adjust

Oil, fuel and water leaks Check Check Check Check

Mechanical links (e.g. fuel solenoid link) Grease Grease Grease

Level battery electrolyte (2) Check Check Check Check

Condition of vibration dampers Check Check Check Check

Alternator insulation resistance (*) Measure Measure Measure Measure

Tightness of nuts and bolts Check Check

Door hinges and locks Grease Grease

Fixation of hoses, cables and pipes Check Check

Inspection by Atlas Copco Service technician

Loading...

Loading...