REFRIGERANT PIPE CONNECTION

4. Refrigerant pipe connection

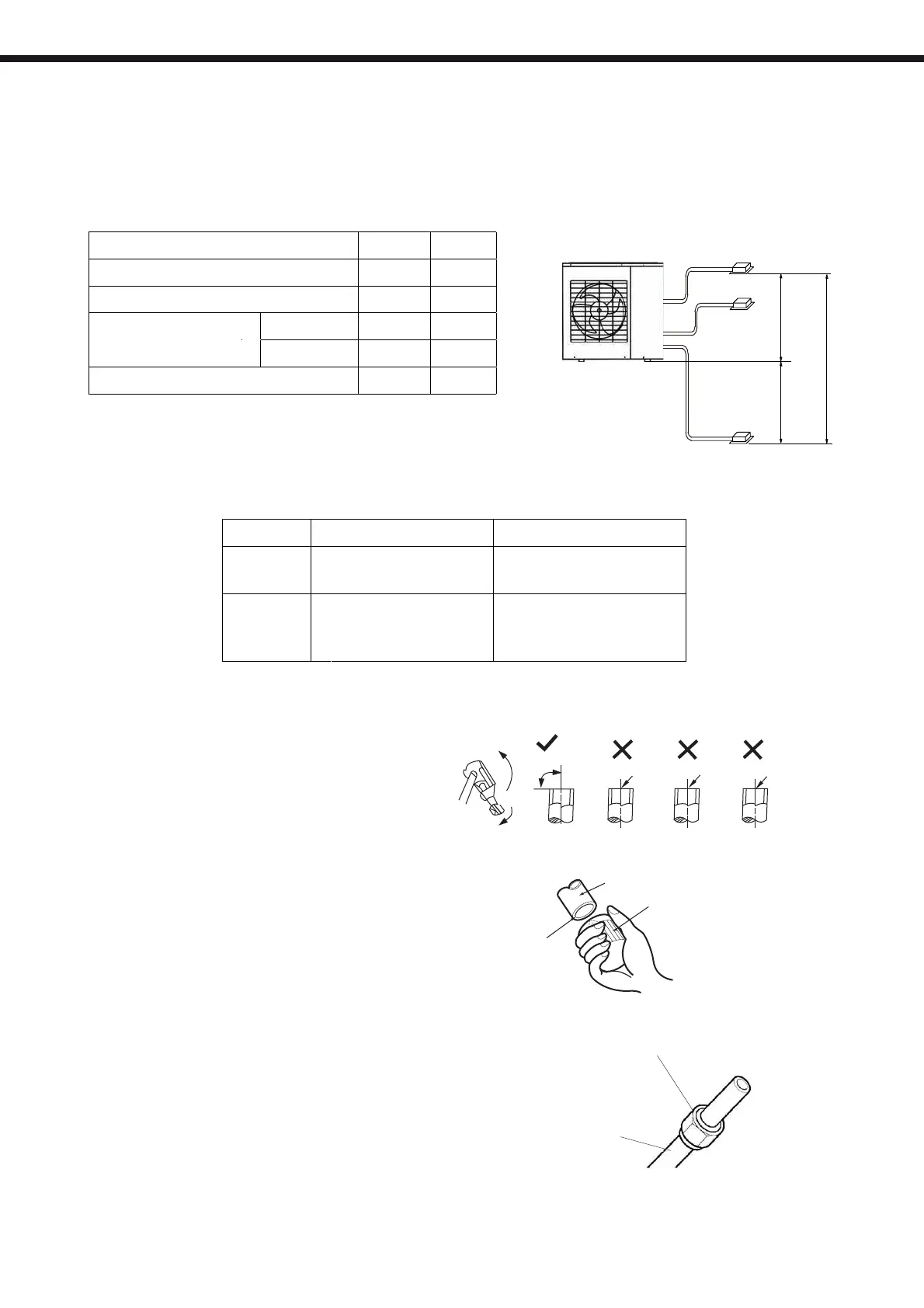

Oblique

。

90

Roughness

Burr

Main cause for refrigerant leakage

is due to defect in the flaring work.

Carry out correct flaring work

using the following procedure:

A: Cut the pipes and the cable.

1. Use the piping kit accessory or pipes

purchased locally

.

2. Measure the distance between the indoor

and the outdoor unit.

3. Cut the pipes a little longer than the

measured distance.

4. Cut the cable 1.5m longer than the pipe

length.

1. Flaring work

Pipe

Reamer

Point down

F

ig.54

Fig.55

B: Burr removal

1

. Completely remove all burrs from the cut

cross section of pipe/tube.

2. Put the end of the copper tube/pipe in a

downward direction as you remove burrs in

order to avoid dropping burrs into the tubing.

F

lare nut

Copper tube

F

ig.56

C: Putting nut on

R

emove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.(not possible

to put them on after flaring work)

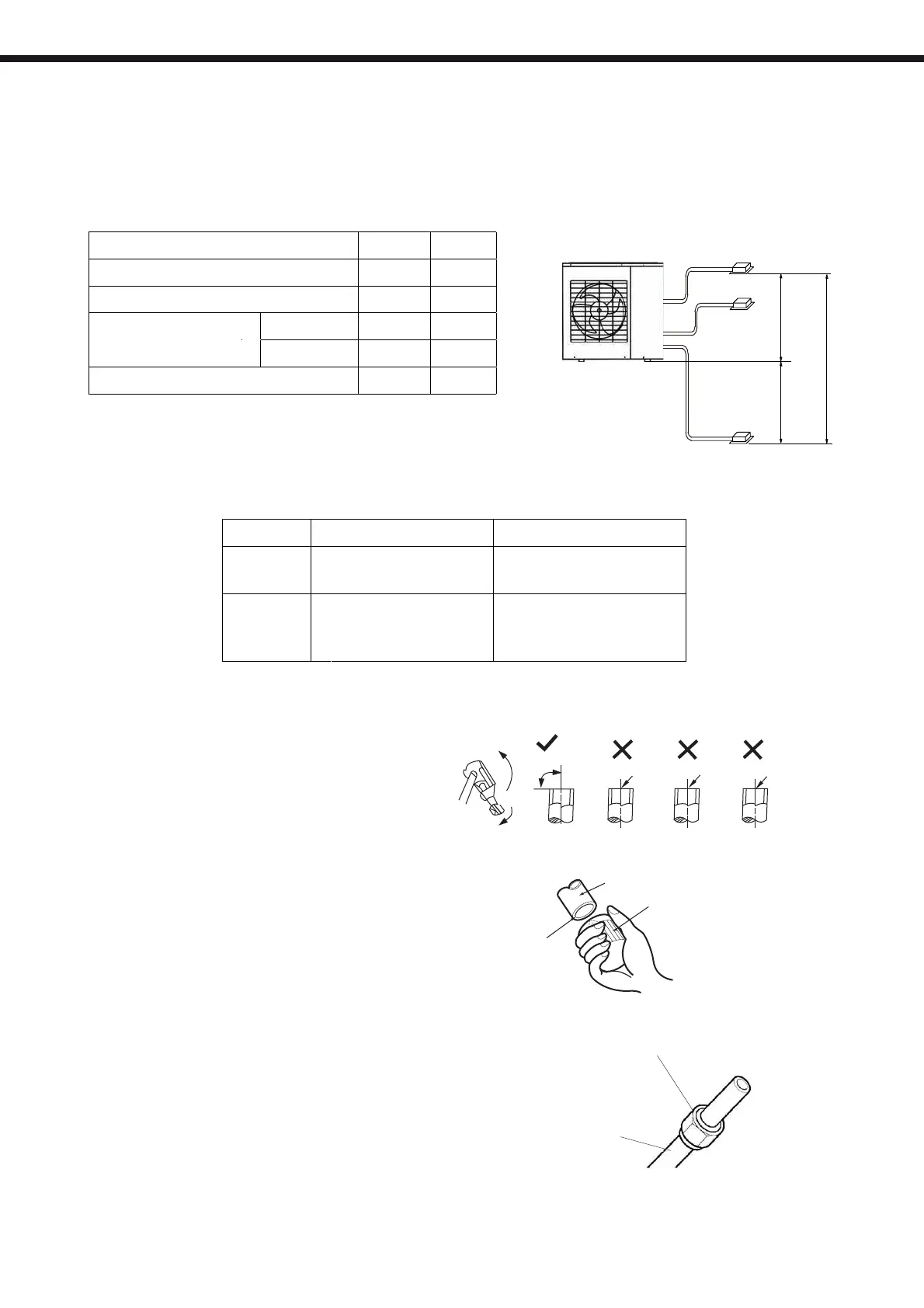

Additional charge (R410A)

M

ax. Length for all rooms (m)

OU higher than IU

OU lower than IU

Max. Length for one indoor unit (m)

Max. height different between

indoor and outdoor unit (m)

Max. height different between indoor units (m)

Before installing, make sure that the height difference, the length of refrigerant pipe and number of bends

between indoor and outdoor units, meet the following specifications.

Outdoor unit

Indoor unit

Charged until

Total Liquid Length 1/4":

22 x (Total length - 15)

(Total Liquid Length 1/4")

Additional

charge

UNIT

AM2

(2 to 1)

AM3

(3 to 1)

Max. lenght:

5m

10m

10m

Max. height difference:

Indoor unit

Indoor unit

Note: If the outdoor unit is installed above the indoor units and the sum

of all the tanks is more than 7m, an oil trap must be installed in the

gas pipe every 3 meters.

AM2 (2 to 1)

(g

)

UNIT

10m 15m

AM3 (3 to 1)

(Total Liquid Length 1/4")

Total Liquid Length 1/4":

22 x (Total length - 10)

38

10

15

40

20 20

15 15

15

10

*(1)

60

Loading...

Loading...