Azbil Corporation

Model: AMT, HDT - CV3000 Series Control Valves

6

2.3 Item to be Checked After Installation and Before Starting Operation

(1) Check that there is no leak from air piping.

(2) Check that the bolts and nuts of the diaphragm case are not loose. Standard

tightening torques are as follows:

For HA2, HA3 (M8) : 12 N.m {120 kg-cm}

For HA4 (M12) : 42 N.m {420 kg-cm}

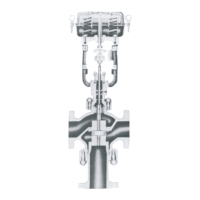

(3) Tighten the packing flange nuts to prevent leak from the gland packing section.

Standard tightening torques are as shown in Table 2-2.

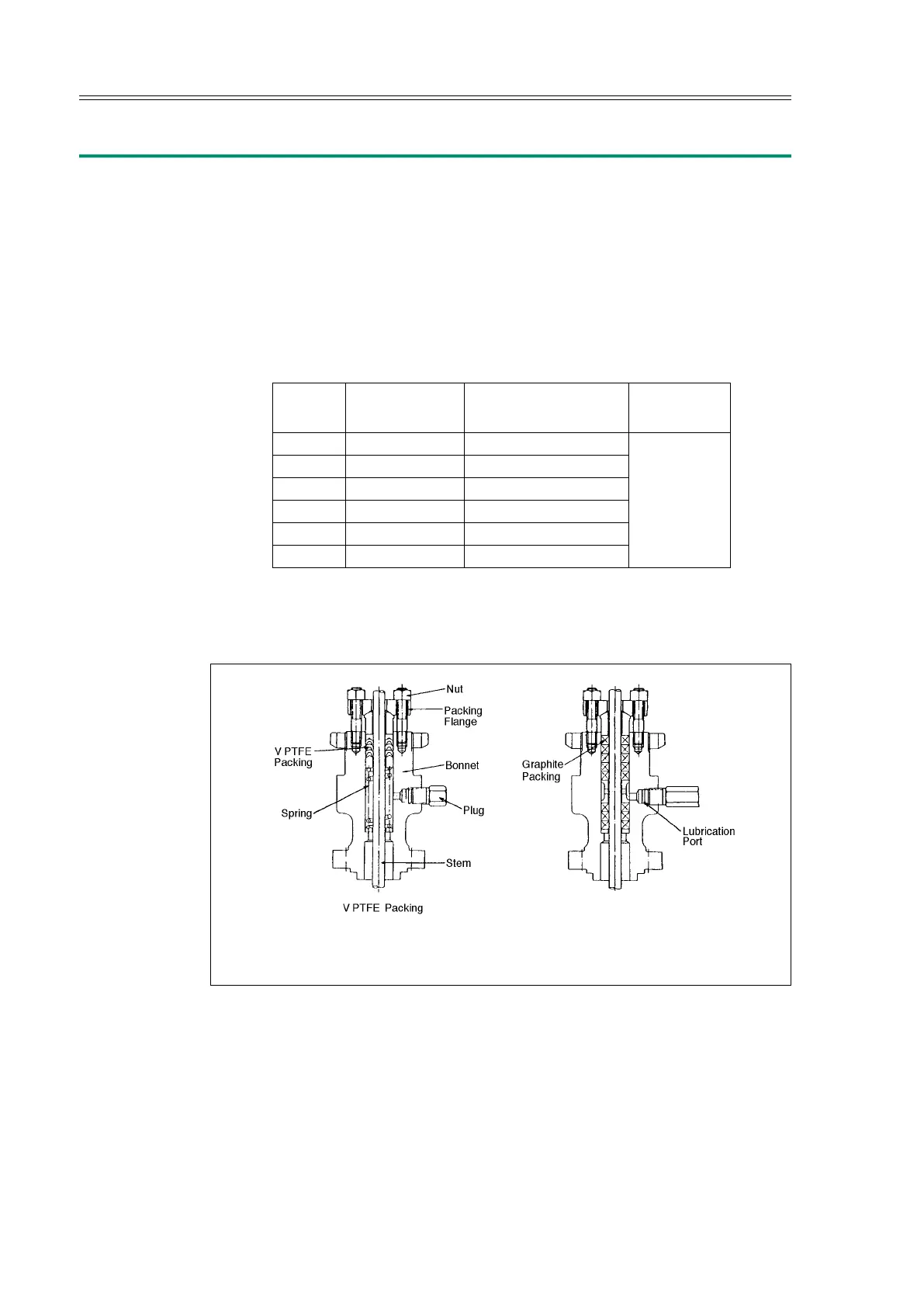

Table 2-2 Tightening Torques of Packing Flange Nuts

Valve Stem

Diameter

(mm)

Graphite Packing

(N.m {kgf-cm})

Metallic Filament Reinforced

Graphite Packing

(N.m {kgf-cm})

V PTFE Packing

(N.m {kgf-cm})

10 3 {30} 7 {70}

0.8 {8}

13 5 {50} 12 {120}

16 8 {80} 18 {180}

20 10 {100} 25 {250}

25 15 {150} 40 {400}

30 20 {200} 50 {500}

Note: The tightening torques mentioned in the above are only to give you reference

values. Note that tightening torques may vary depending on the type of

packing.

Graphite Yarn packing

Fig. 2-1 Gland Section

(4) If the valve is provided with a lubricator as shown in Fig. 2-2, check whether

the bonnet section has been lubricated or not. To do this, loosen the lubricator

handwheel and turn the squeeze screw. If the squeeze screw turn lightly, and

grease in the lubricating procedure mentioned below. (If the squeeze screw turns

heavily, this means that grease has been applied.)

Loading...

Loading...