1. It is now time to install the new countershaft bearing that was provided in your kit. It is

important that this step be done AFTER installing the tapered bearing adapter. This is to

avoid cooking your new countershaft bearing while heating the case in that step.

2. Wipe out the countershaft bearing bore with a clean rag. Apply a thin coating of oil to both

the bearing bore and the outer diameter of the countershaft bearing.

3. Use a countershaft bearing tool (BAKER TOOLE-07 or equivalent) to press the bearing into

the transmission case. You want to press on the outside of the ‘cup’, just as you did during

removal. See the appropriate tool instructions and your Factory Service Manual for details.

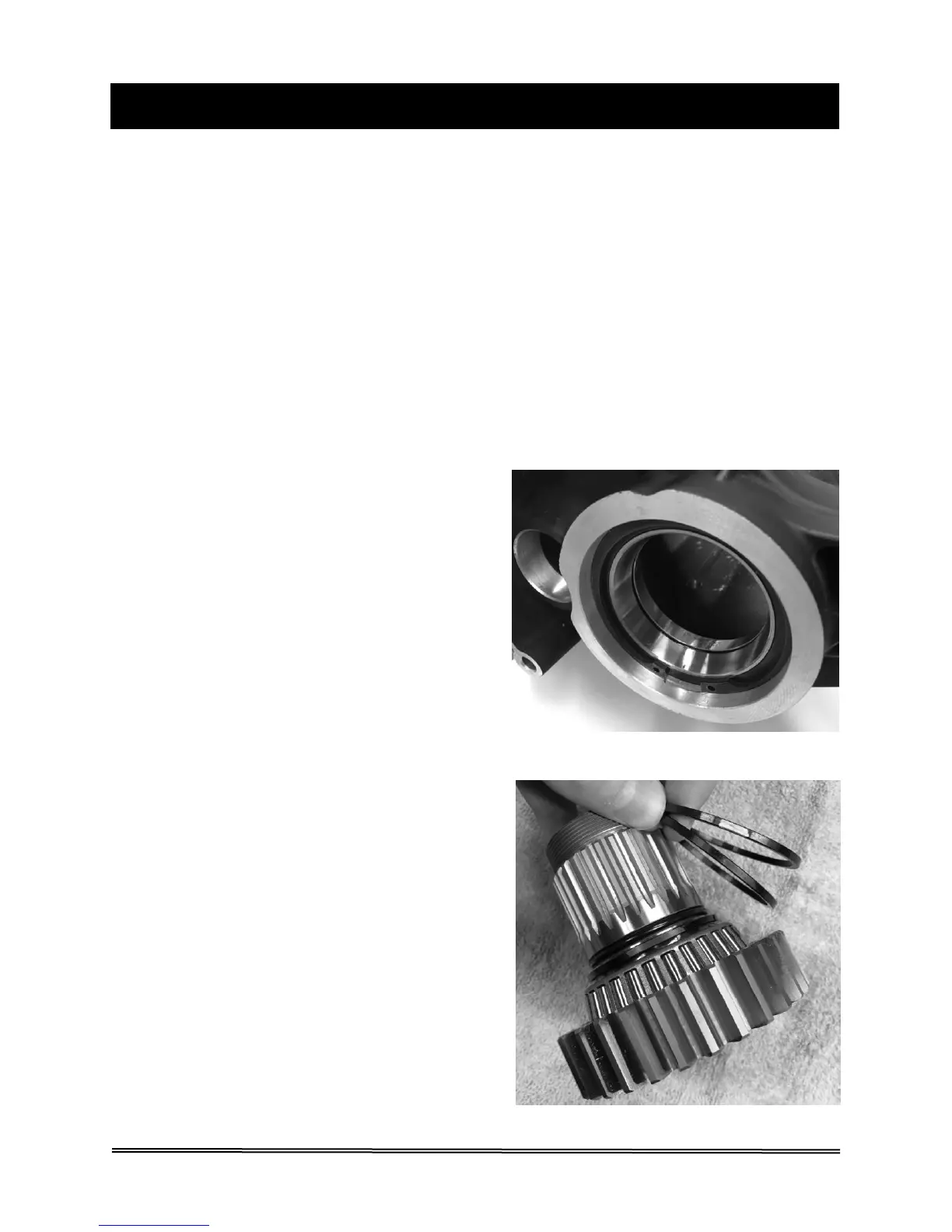

1. Before installing the main drive gear,

apply a thin coating of transmission oil

to the tapered bearing races and the

main drive gear O-ring; see figure 17.

A thicker oil could give you a false

reading when checking endplay.

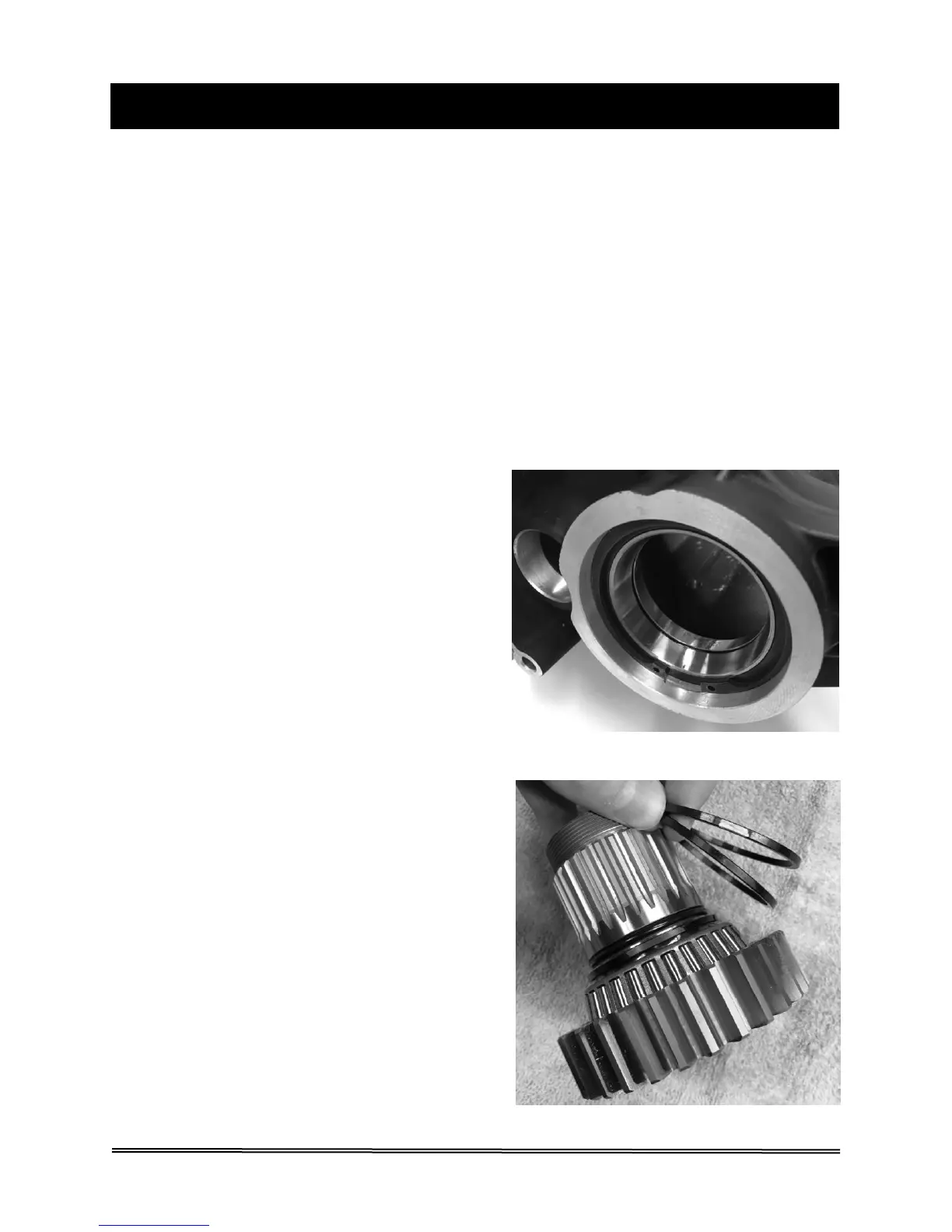

2. Each kit comes with three spacers for

setting up end play in the tapered

roller bearings: .102” (white), .104”

(green) and .106” (blue) thick. The

most commonly used spacer (.104”,

green) is pre-installed on the main

drive gear. The .102” and .106”

spacers are included for cases where

bearing end play is outside of the

acceptable range with the pre-

installed .104” spacer; see figure 18.

Apply a thin coating of transmission oil

to the main drive gear O-ring each

time you change the spacer.

FIGURE 18 | MAIN DRIVE GEAR WITH PRE-INSTALLED

SPACER AND TWO EXTRA SPACERS; LUBE O-RING

COUNTERSHAFT BEARING INSTALLATION

MAIN DRIVE GEAR INSTALLATION

INSTALLING THE C/S BEARING & MAIN DRIVE GEAR

FIGURE 17 | LIGHTLY OIL BEARING RACES

BEFORE INSTALLING THE MAIN DRIVE GEAR

Loading...

Loading...