9

924.674.3 - GBINSTRUCTIONS PERTAINING TO THE INSTALLER

16. INSTALLATION OF FLUE AND AIR DUCTS

Models 240 Fi - 1.240 Fi

We guarantee ease and exibility of instal lation for a gas-

red forced draught boiler thanks to the ttings and xtures

supplied (described below).

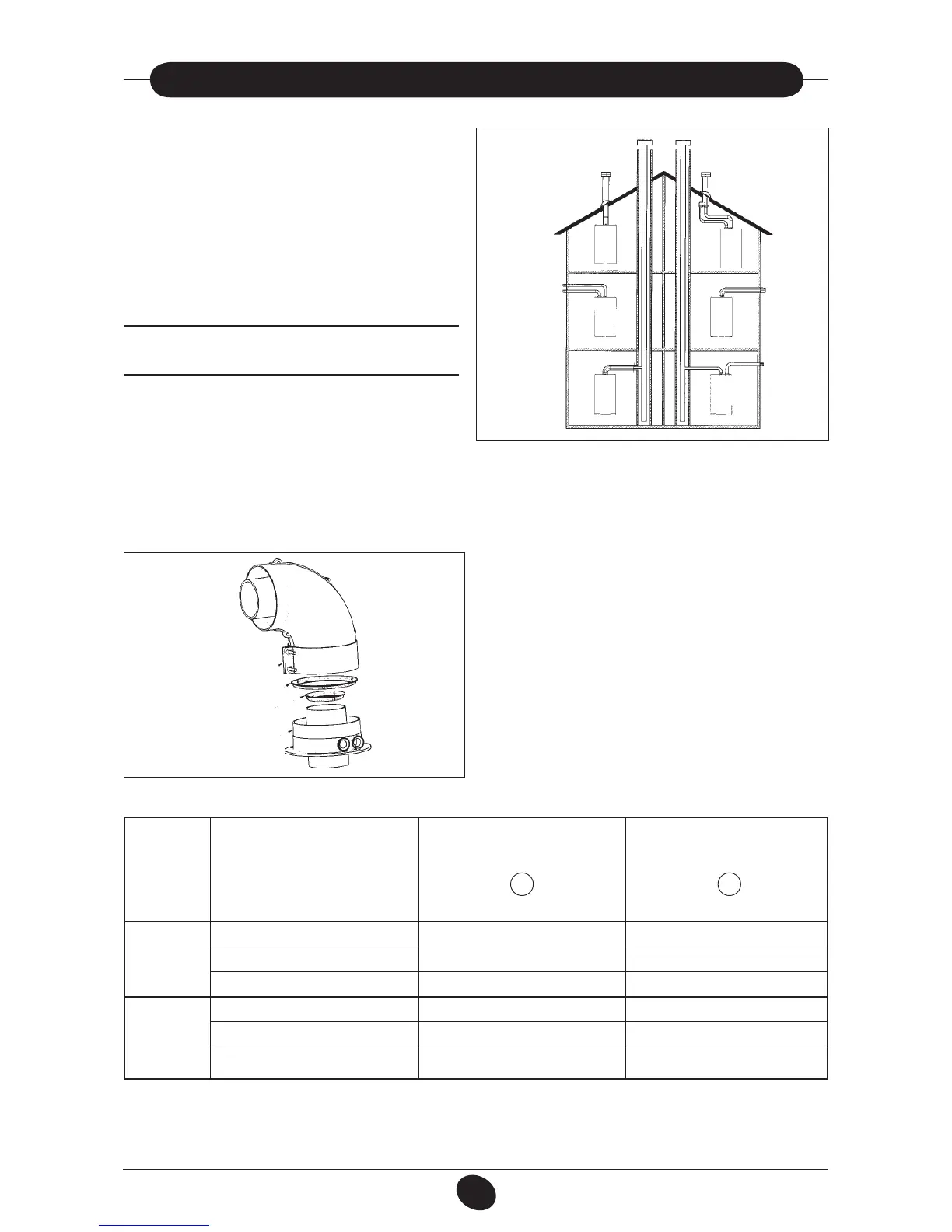

The boiler is especially designed for connection to an

exhaust ue / air ducting, with either coaxial, vertical or

horizontal terminal. By means of a splitting kit a two-pipe

system may also be installed.

Exclusively install fittings supplied by the manufac-

turer.

WARNING : To guarantee more operating insurance it

is necessary to assure the flue pipes to the wall using

the apposite clamps.

Figure 7

0503_0905/CG1638

Figure 8

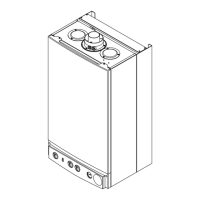

… COAXIAL FLUE - AIR DUCT (CONCENTRIC)

This type of duct allows to disengage exhaust gases and to draw combustion air both outside the building and in case a

LAS ue is tted.

The 90° coaxial bend allows to connect the boiler to a ue-air duct in any direction as it can rotate by 360°. It can moreover

be used as a supplementary bend and be coupled with a coaxial duct or a 45° bend.

0511_2701/CG1750

If the ue outlet is placed outside, the ue-air ducting must

protrude at least 18mm out of the wall to allow alluminium wea-

thering tile to be tted and sealed to avoid water leakages.

Ensure a minimum downward slope of 1 cm towards the

outside per each metre of duct length.

•

A 90° bend reduces the total duct length by 1 metre.

•

A 45° bend reduces the total duct length by 0.5 me-

tre.

The first 90° bend is not included in the maximum avai-

lable length.

Securing clamp

Concentric outlet

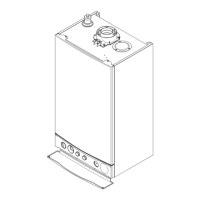

A

B

Boiler

model

240 Fi

1.240 Fi

280 Fi

0 ÷ 1

1 ÷ 2

2 ÷ 5

0 ÷ 1

1 ÷ 2

2 ÷ 4

Length (m)

Air suction

RESTRICTOR

B

Yes

No

No

Yes

No

Flue

RESTRICTOR

A

Yes

No

No

Yes

No

No