36 EcoBlue System 7219708 - 01 (04/15)

5 Before Installation

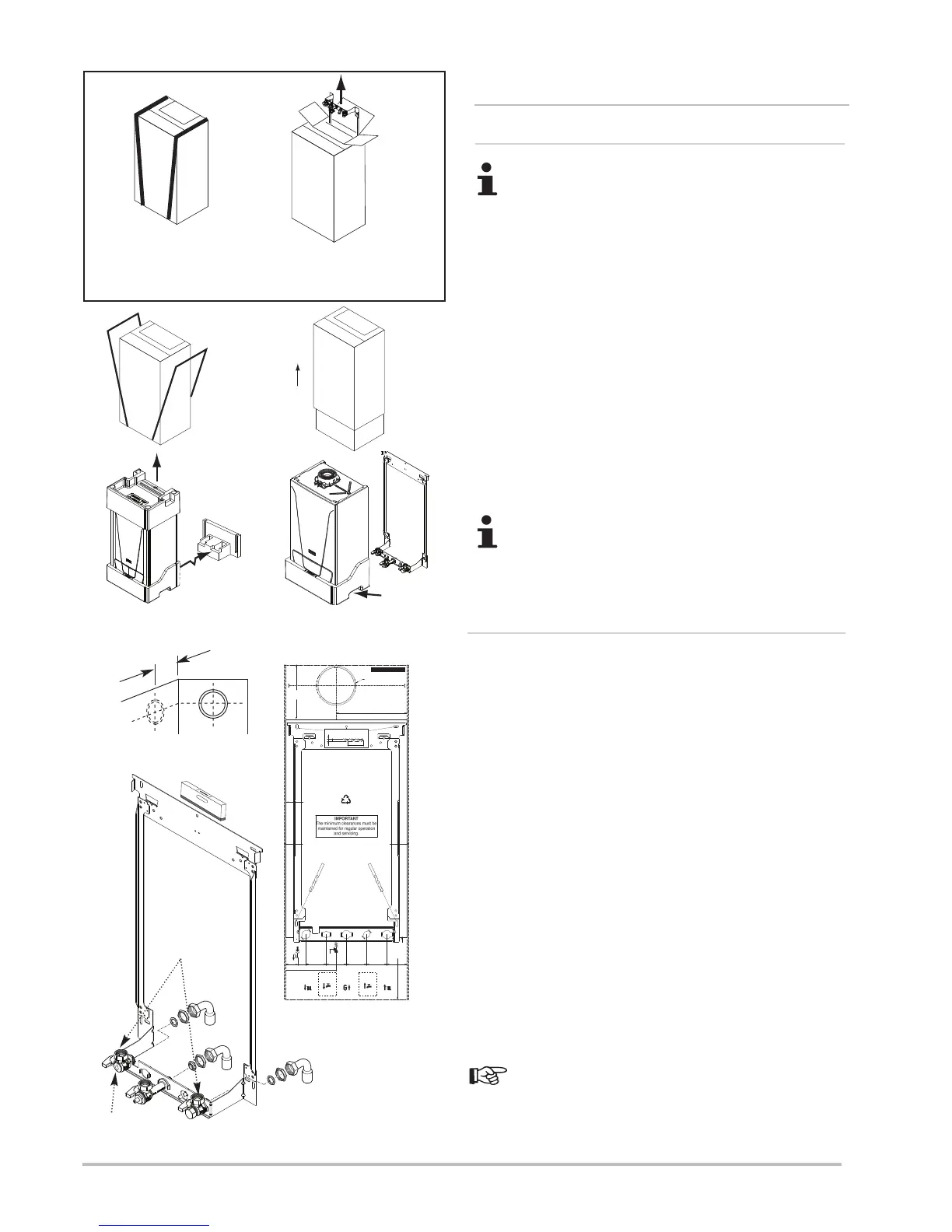

5.5 Unpacking & Initial Preparation

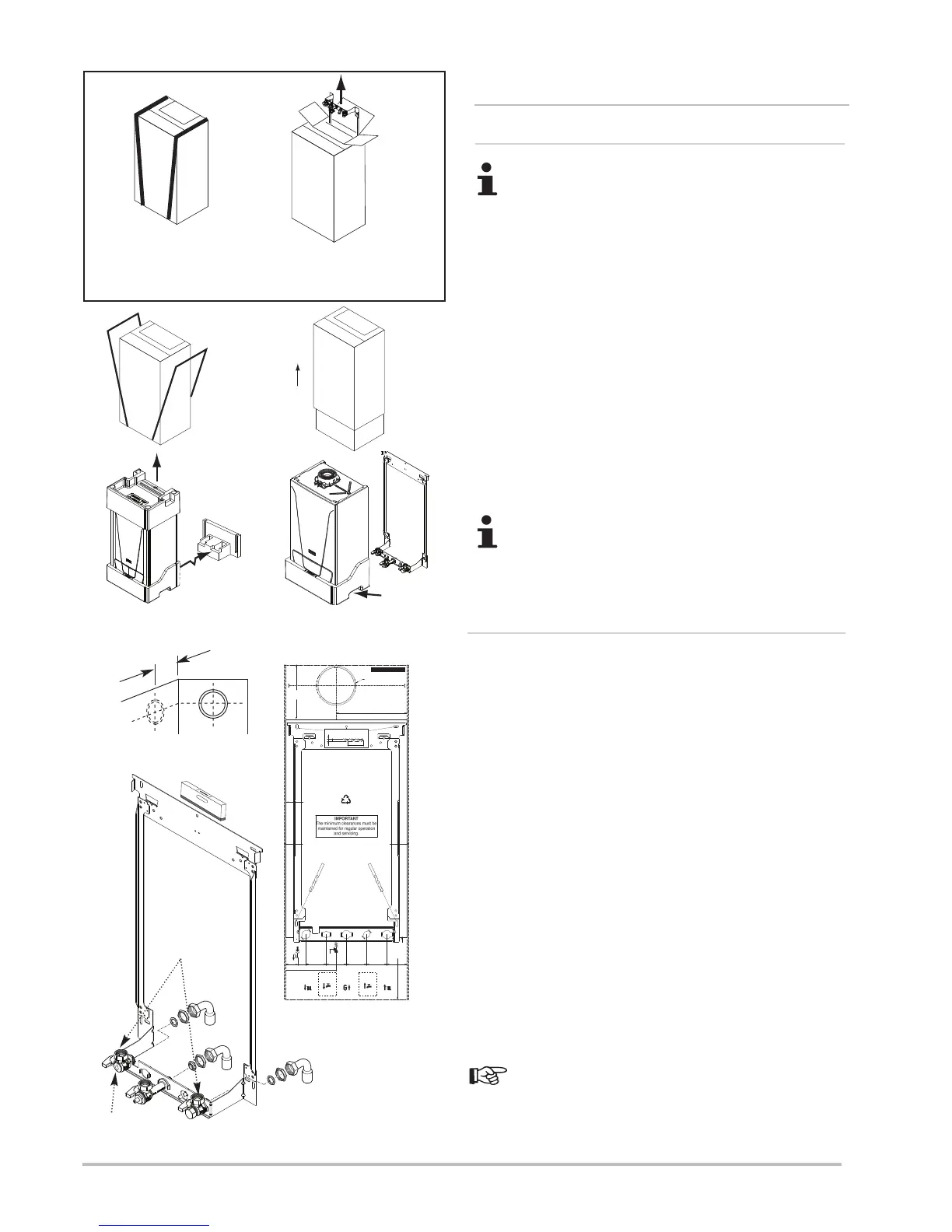

5.5.1 Unpacking

RISK ASSESSMENT - Before commencing the

installation it is recommended that the ‘Five Steps to

Risk Assessment’ document published by the HSE is

consulted, and an assessment performed as described.

GAS SUPPLY - The gas supply, gas type and pressure

must be checked for suitability before connection.

1. See ‘Section 2.3.1 Handling’ before unpacking or lifting the

boiler.

2. Follow the procedure on the carton to unpack the boiler or

see Fig. 14a.

3. If pre-plumbing (Fig. 14) - the wall jig and fitting kit can be

removed without removing the carton sleeve. Simply slide

banding to the edge and open the perforated flap, lift out the jig,

fitting kit and instructions. If the boiler is to be install at a later

date, close the flap and reposition the banding straps, the boiler

can now be store safely away.

A small amount of water may drain from the boiler in the

upright position.

5.5.2 Initial Preparation

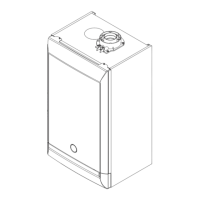

1. After considering the location position the fixing template on

the wall ensuring it is level both horizontally and vertically.

2. Mark the position of the fixing slots for the wall jig indicated on

the template.

3. Mark the position of the centre of the flue hole (rear exit). For

side flue exit, mark as shown (Fig. 15).

4. If required, mark the position of the gas and water pipes.

Remove the template (Fig. 17).

5. Cut the hole for the flue (minimum diameter 116mm).

6. Drill the wall as previously marked to accept the wall plugs

supplied. Secure the wall jig using the fixing screws.

7. Using a spirit level ensure that the wall jig is level before

finally tightening the screws (Fig. 16).

8. Connect the gas and water pipes to the valves on the wall jig

using the copper tails supplied. Ensure that the sealing

washers are fitted between the connections.

Fit a suitable filling loop as described in the instructions

supplied with it.

Pressure

Relief

Valve

(15mm)

Condensate

Drain

Part No. 7212143 DRAFT A

5 mm Minimum

Side Clearance

5 mm Minimum

Side Clearance

116mm Dia Minim um

Aperture For Flue Tube

Side Flue

Centre Line

Vertical Flue

Centre Line

175 mm

Minimum

Clearance

Profile of

Outercase

228 mm

150 mm

Minimum

Clearance

Boiler Wall Mounting Plate

Fixing Slots

38.5mm

26.5

mm

65 mm 65 mm 65 mm 65 m m 65 mm

Ø 8 mm

50 mm

162.5mm (PRV)

Hot Water

Outlet

(15mm)

Combi Only

Not System

Cold Water

Inlet

(15mm)

Heating

Return

(22mm)

Heating

Flow

(22mm)

Gas

Inlet

(22mm)

Combi Only

Not System

Part No. 7212143

200 mm

Recommended

Wall Template

130mm

(140mm on 32

model)

For Side Flue Exit

Fig. 15

Fig.16

Heating Flow

3/4” BSP

Connections

Fig. 17

Fig. 14a

SNAP OFF

Loading...

Loading...