Operation

EL290434 Version: 3.2.2

5.2.5 TwinSAFE reaction times

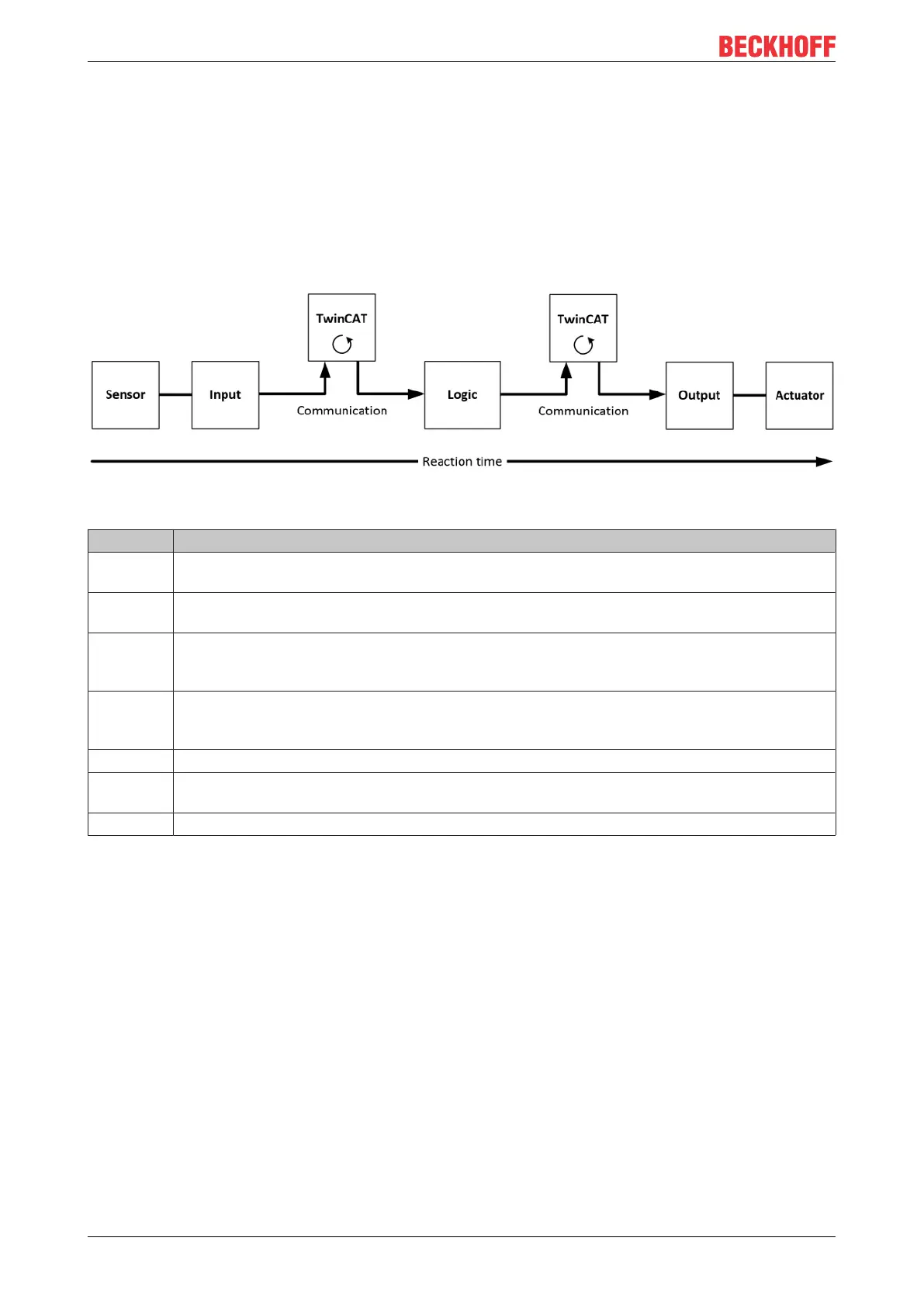

The TwinSAFE terminals form a modular safety system that exchanges safety-oriented data via the Safety-

over-EtherCAT protocol. This chapter is intended to help you determine the system's reaction time from the

change of signal at the sensor to the reaction at the actuator.

Typical response time

The typical response time is the time required for transferring a piece of information from the sensor to the

actuator, when the whole system operates normally, without error.

Fig.15: Typical response time

Definition Description

RT

Sensor

Response time of the sensor, until the signal is made available at the interface. Typically

provided by the sensor manufacturer.

RT

Input

Response time of the safe input, e.g. EL1904 or EP1908. This time can be found in the

technical data. In the case of the EL1904 it is 4ms.

RT

Comm

Response time of the communication. This is typically 3 times the EtherCAT cycle time, since a

new Safety-over-EtherCAT telegram has to be generated before new data can be sent. These

times depend directly on the higher-level standard controller (cycle time of the PLC/NC).

RT

Logic

Response time of the logic terminal. This is the cycle time of the logic terminal and typically

ranges from 500µs to 10ms for the EL6900, depending on the size of the safety project. The

actual cycle time can be read from the terminal.

RT

Output

Response time of the output terminal. This is typically between 2 and 3ms.

RT

Actuator

Response time of the actuator. This information is typically provided by the actuator

manufacturer

WD

Comm

Watchdog time of the communication

The typical response time is based on the following formula:

3 * 3 *

typ Sensor Input Comm Logic Comm Output Actuator

ReactionTime RT RT RT RT RT RT RT= + + + + + +

with

5 4 3*1 10 3*1 3 20 48

typ

ReactionTime ms ms ms ms ms ms ms ms= + + + + + + =

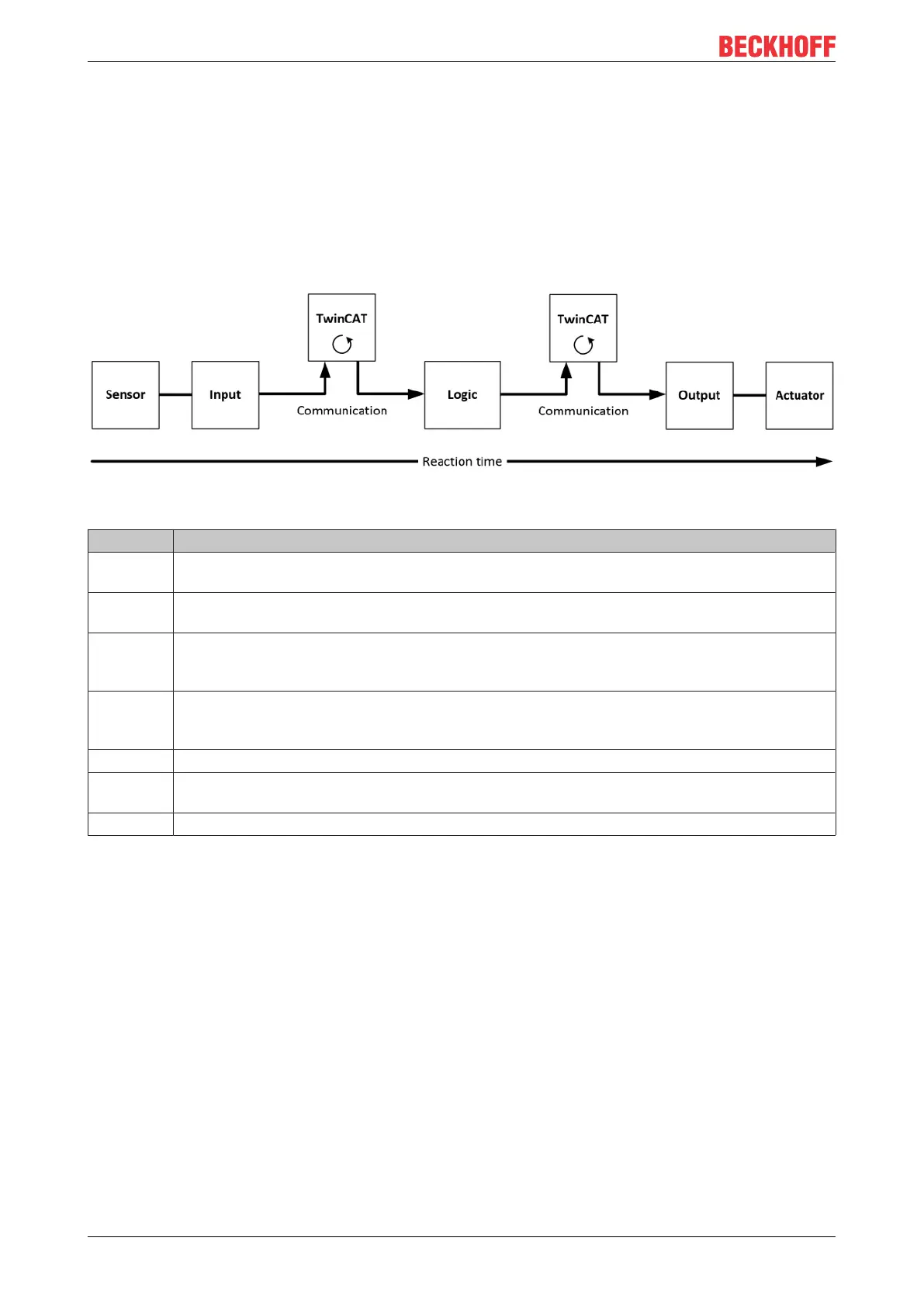

Worst case response time

The worst-case response time is the maximum time required for switching off the actuator in the event of an

error.

Loading...

Loading...