6

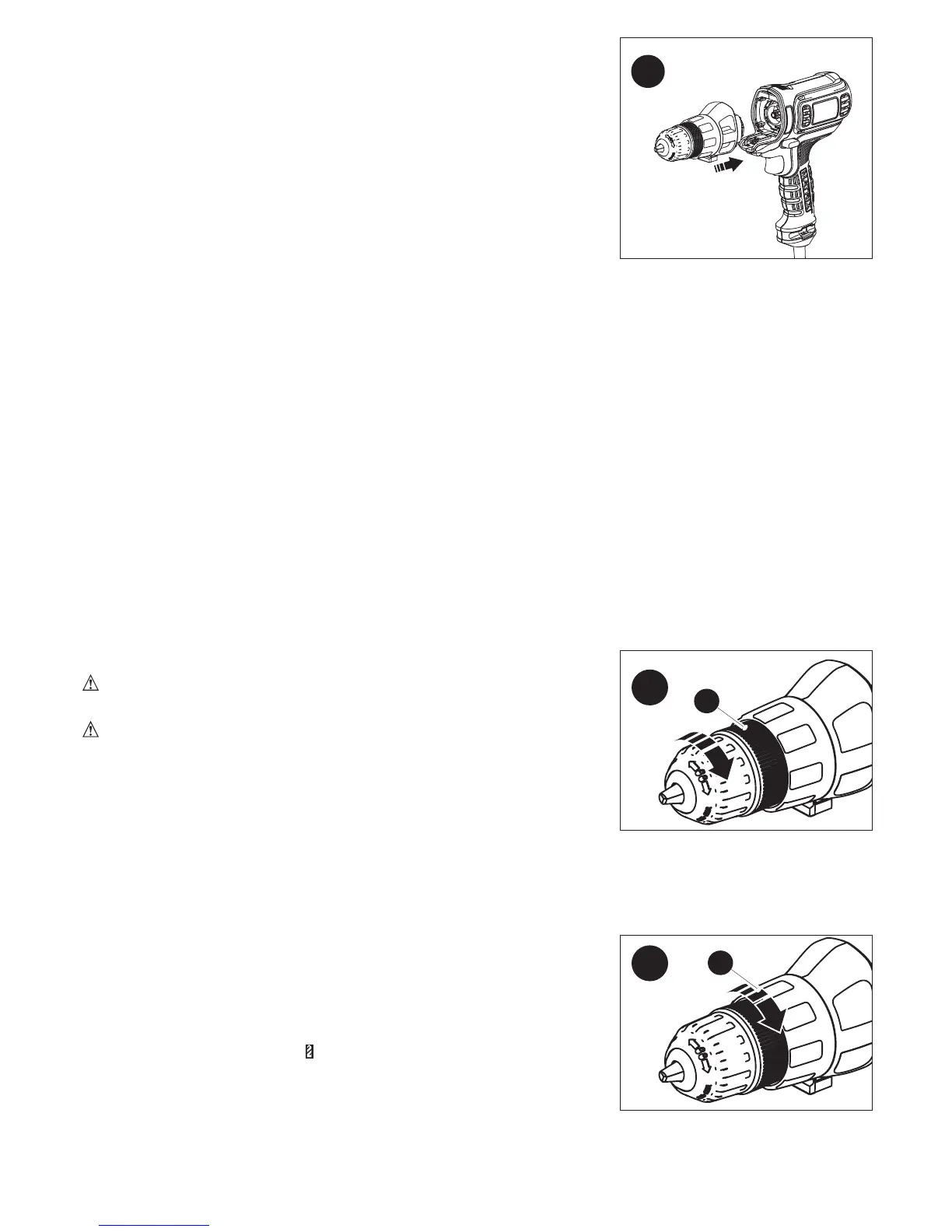

• Toremoveanattachment,depressthereleasebutton(3)and

taketheattachmentoffthetool.

• Totanattachment,lineitupwiththetoolasshownandpush

it onto the Power Unit until it snaps into place and an audible

clickisheard.

• Ensureattachmentissecurelyattachedbygentlypullingit

away from the Power Unit.

NOTE: Only use attachments that are specifically designed

for and compatible with the Power Unit.

NOTE: Refer to individual attachment instruction manuals for

specific safety warnings and operating instructions before oper-

ating attachments with the Power Unit.

OPERATING: DRILL/SCREWDRIVER ATTACHMENT

FITTING AND REMOVING A DRILL BIT OR SCREWDRIVER BIT

Thedrill/screwdriverattachment(5)isfittedwithakeylesschuck(6)toallowforaneasyexchangeofbits.

• UnplugthePowerUnitbeforeinstallingorremovingattachments.

• Openthechuckbyturningthefrontpartclockwisewithonehandwhileholdingtherearpart

with the other.

• Insertthebitshaftintothechuck.

• Firmlytightenthechuckbyturningthefrontpartcounterclockwise.

• Toremovethescrewdriverbitfromtheholder,liftthebitfromtherecess.

• Tostorethescrewdriverbit,firmlypushitintotheholder(4).

SCREW DRIVING

• Always use the correct type and size of screwdriver bit.

• If screws are difficult to tighten, try applying a small amount of washing liquid or soap as a lubricant.

• Always hold the tool and screwdriver bit in a straight line with the screw.

•

Fordrivingfasteners,thereversingbuttonshouldbepushedtotheleft.Usereverse(button

pushedtotheright)forremovingfasteners.Whenmovingfromforwardtoreverse,orvice

versa, always release the trigger switch first.

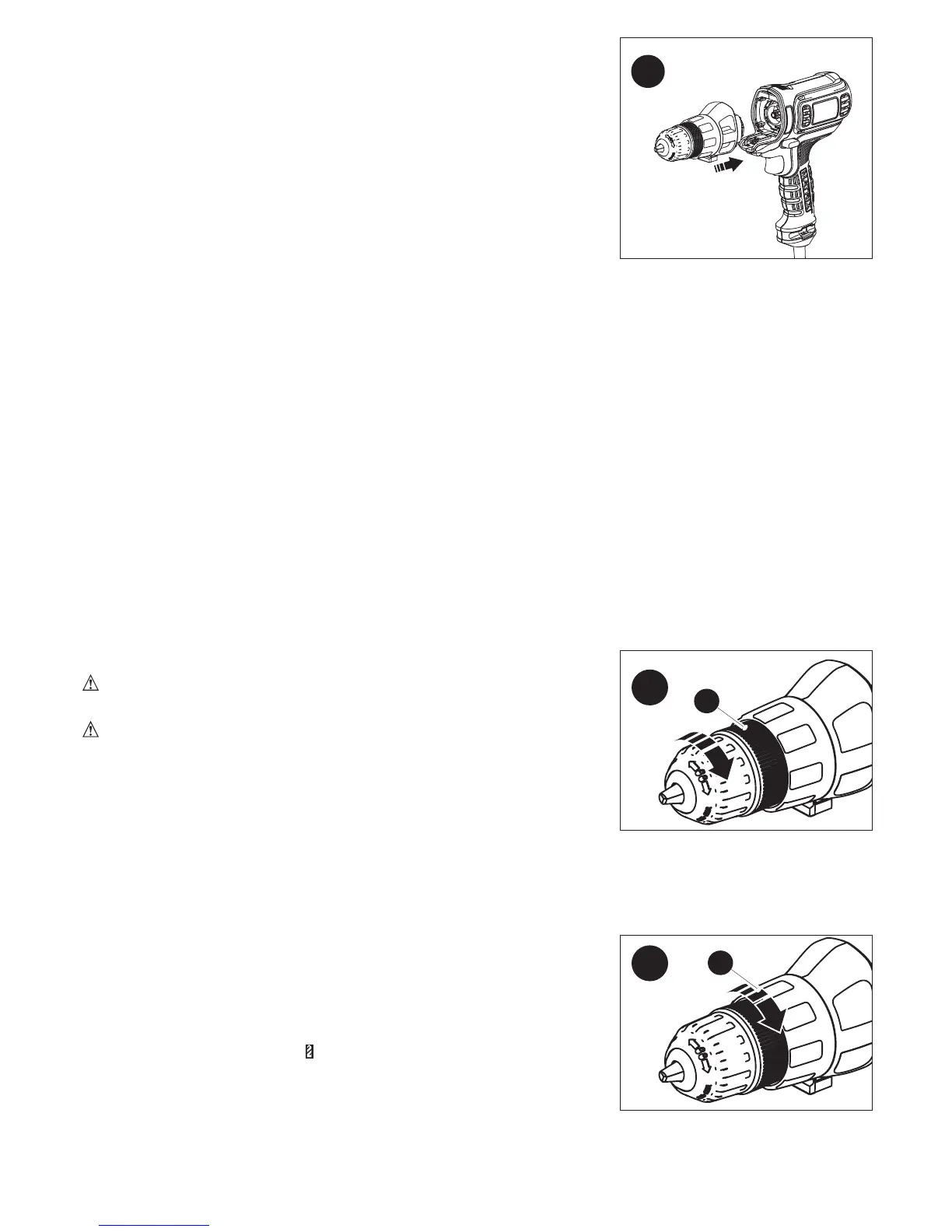

KEYLESS CHUCK - FIGURE B

WARNING: MakecertainthePowerUnitisunpluggedto

prevent switch actuation before installing or removing attachments.

WARNING: Donotattempttotightenorloosendrillbits(or

anyotheraccessory)bygrippingthefrontpartofthechuckand

turningthetoolon.Damagetothechuckandpersonalinjurymay

occur when changing accessories.

Toinsertadrillbitorotheraccessory:

1. Grasptherearhalfofthechuck(6)withonehandanduse

yourotherhandtorotatethefronthalfinthecounterclockwisedirection,asviewedfromthe

chuckend.

2. Insertthebitorotheraccessoryfullyintothechuck,andtightensecurelybyholdingtherearhalfof

thechuckandrotatingthefrontportionintheclockwisedirectionasviewedfromthechuckend.

TORQUE CONTROL - FIGURE C

Thistoolisfittedwithatorqueadjustmentcollar(7)toselectthe

operating mode and to set the torque for tightening screws. Large

screwsandhardworkpiecematerialsrequireahighertorque

settingthansmallscrewsandsoftworkpiecematerials.

• Fordrillinginwood,metalandplastics,setthecollartothe

drilling position symbol .

• Forscrewdriving,setthecollartothedesiredsetting.Ifyoudo

notyetknowtheappropriatesetting,proceedasfollows:

• Setthecollartothelowesttorquesetting.

• Tightenthefirstscrew.

• Iftheclutchratchetsbeforethedesiredresultisachieved,increasethecollarsettingand

continue tightening the screw. Repeat until you reach the correct setting. Use this setting

for the remaining screws.

C

7

B

6

A

Loading...

Loading...