ACS 753, ACS 763, ACS 863 Service Manual

SP00D00609 2018-03-26Robert Bosch GmbH

15

Introduction

Filter Maintenance

The lter is designed to trap acid and particulates,

and to remove water from refrigerant. To meet

this mandate, the lter must be replaced after

(SEE TABLE) of refrigerant has been ltered.

The unit gives a warning when (SEE TABLE) of

the lter capacity has been used; the unit locks

down when the

(

SEE TABLE) lter capacity has

been reached and will no longer function.

Check Remaining Filter Capacity

1. Call up the Main Menu.

2. Select NEXT icon.

3. Select MENU icon.

4. Select Filter Maintenance from the

Maintenance Menu or when the machine

prompts. The machine displays:

REMAINING FILTER CAPACITY: XXX.XYY

REPLACE FILTER NOW?

• The machine displays amount of lter ca-

pacity remaining until the machine locks

down. This message may occur at anytime

during the course of an A/C system main

-

tenance action.

5. Select OK icon to change the lter; Select

ESC icon to resume using the machine.

Replace the Filter

1. If OK icon was selected to change the lter,

the unit will clear the lter, then prompts for

the new lter code to be entered:

ENTER NEW FILTER SERIAL NUMBER

NOTE: If SERIAL NUMBER WRONG is

displayed, the serial number has been incorrectly

entered or the lter has already been used in this

machine.

2. Use the keypad to enter the serial number

that appears on the new lter and select OK

icon to continue.

• The machine clears the existing lter and

displays:

TURN POWER OFF

AND REPLACE FILTER

1

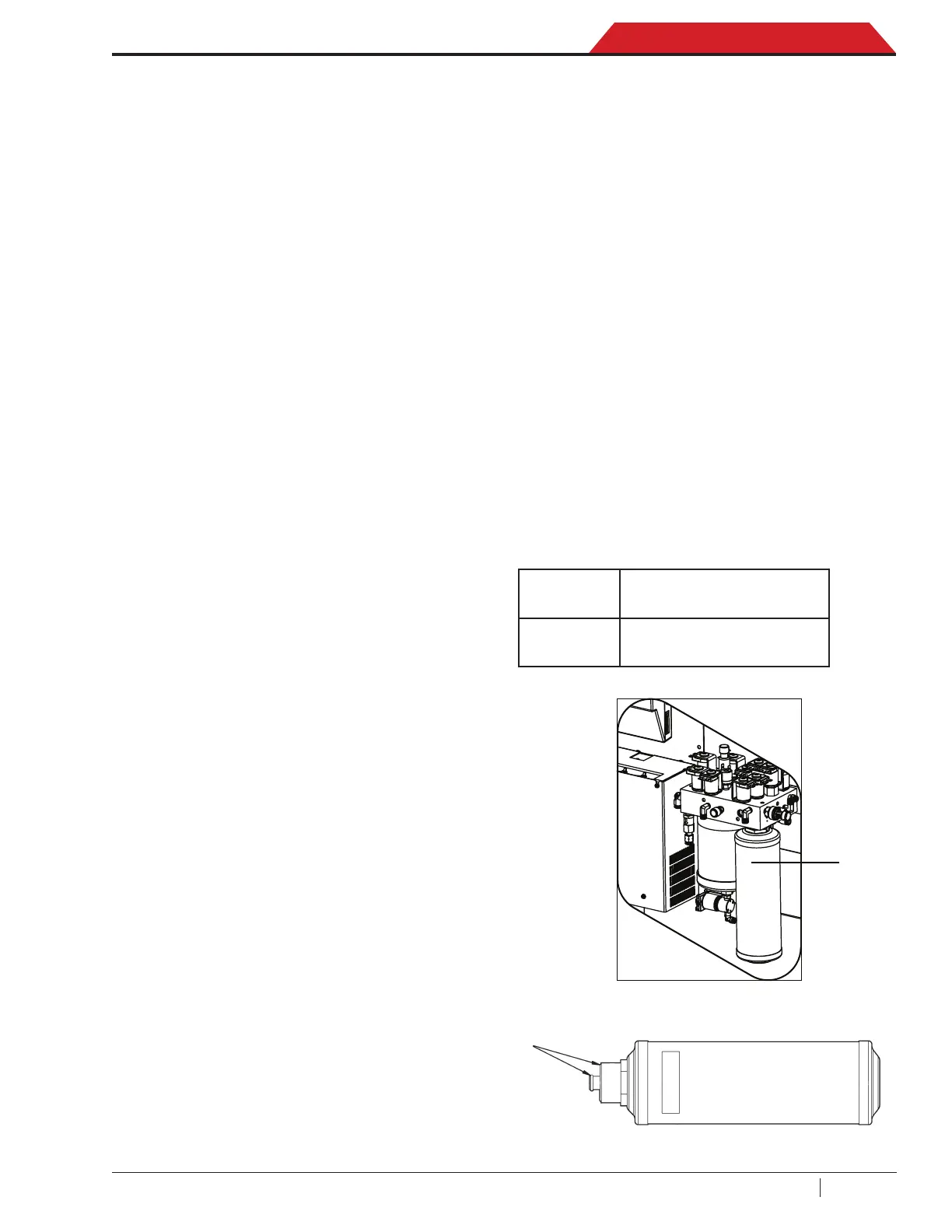

Figure 1-4. Filter Location

3. Switch off the machine.

4. Open the service rear door.

5. Remove the old lter (1) by turning it clock-

wise. Refer to Figure 1-4.

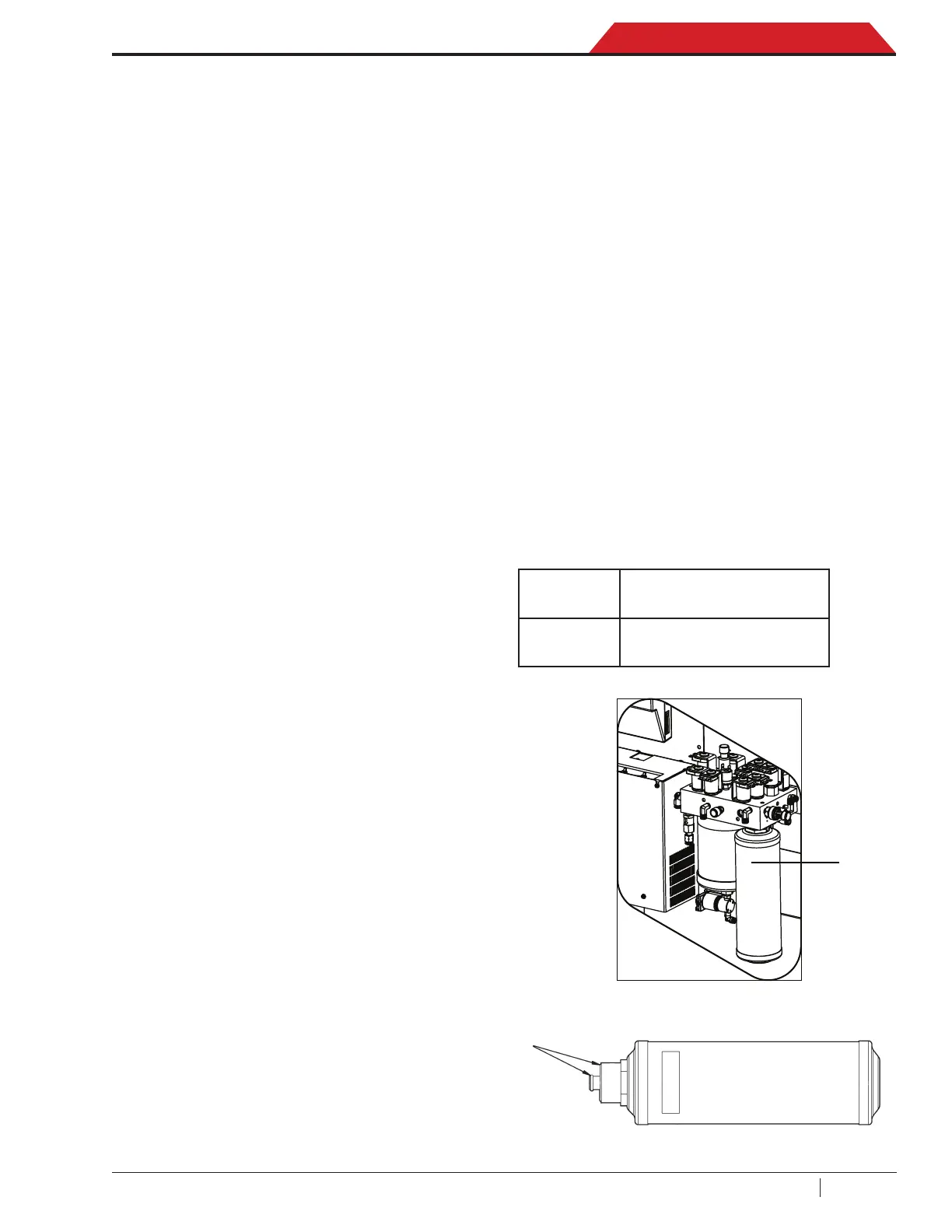

6. Look at the new lter. Verify both O-rings

are lubricated and correctly located in the

grooves as shown in Figure 1-5.

7. Install the new lter by threading it counter-

clockwise into place. Verify the lter is posi-

tioned correctly. Tighten the lter to 20 Nm.

8. Close the service rear door.

9. Switch on the machine.

10. Machine starts with vacuum pump oil

change (Refer to the “Vacuum Pump Main-

tenance” in this section).

11. Recycle the lter that was removed from

the machine according to the laws in your

jurisdiction.

CAUTION:UseonlyauthenticBoschlters

in this machine. All performance tests and

claimsarebasedonusingthisspeciclter.

Model

R134a

Replacement lter at: 68 kg

(alert 56 kg)

Model

R1234yf

Replacement lter at: 150 kg

(alert 138 kg)

Figure 1-5. O-ring Location

O-rings

• Connect a second recovery machine to

the tting (1) located on the side of the

machine. See Figure 1-3. Run a recovery

to remove the refrigerant sampled by the

refrigerant identier in the machine.

Loading...

Loading...