ACS 753, ACS 763, ACS 863 Service Manual

SP00D00609 2018-03-26Robert Bosch GmbH

55

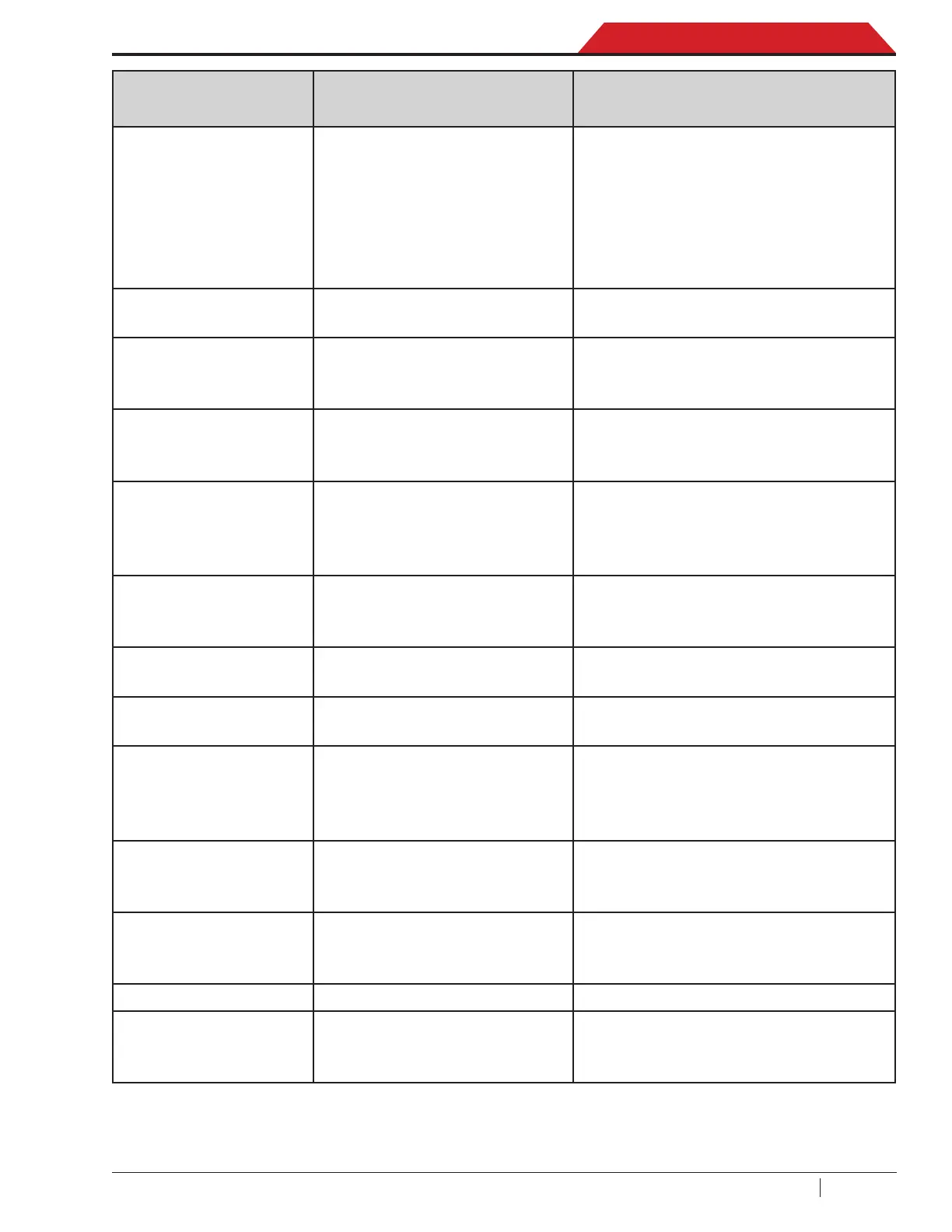

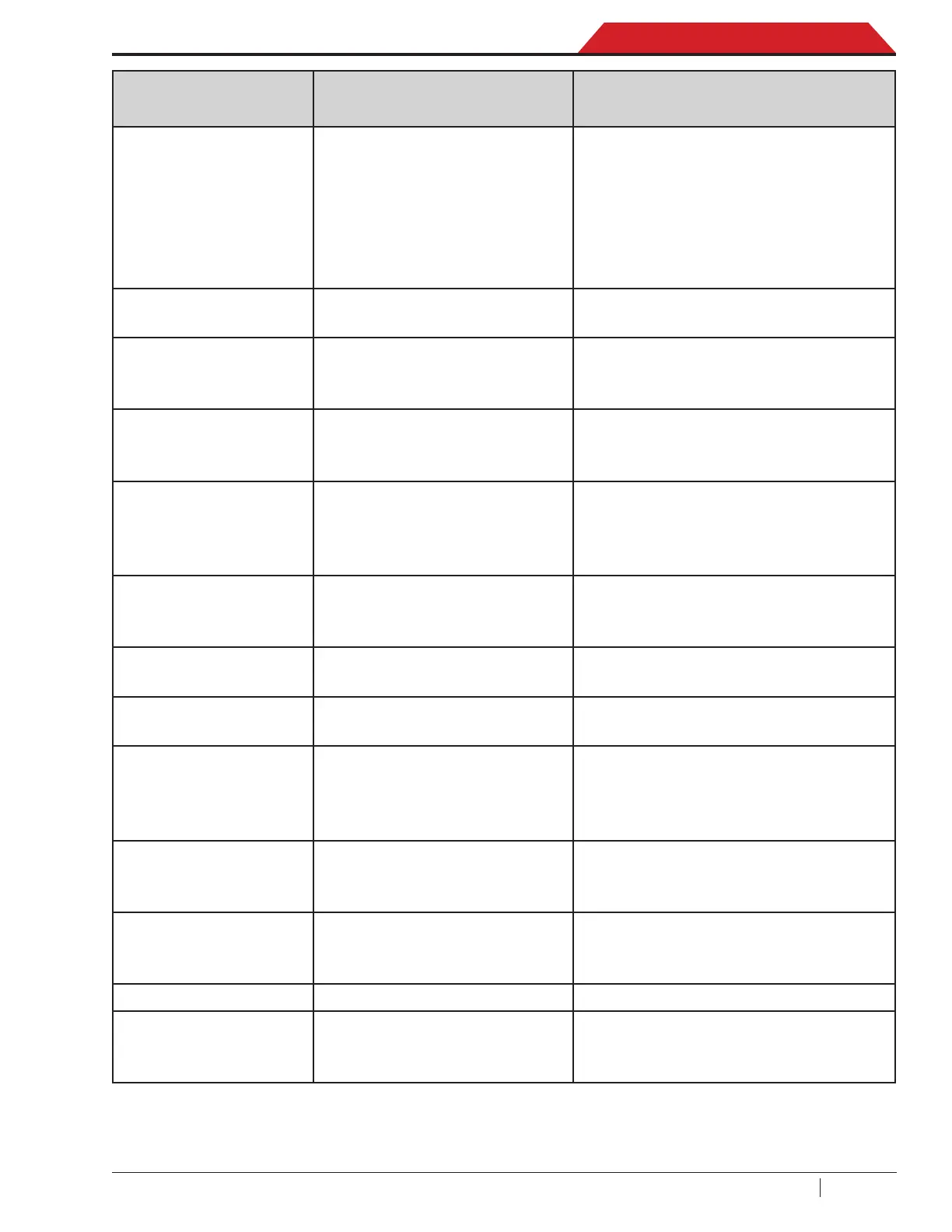

Diagnostics and Testing

PROCEDURE ERROR/WARNING DESCRIPTION OF ERROR/

WARNING

Oil Inject Oil inject error. Inject: XXXYY 1. Check if enough oil is present in oil

bottle.

2. Check for oil inject tube kinks or

cuts.

3. Check for oil inject solenoid failure.

4. Check for Oil inject stuck check

valve.

Recover No pressure on inlets.

Recover Anyway?

Select OK (Yes) or ESC icon (No).

Service Vacuum Vacuum halted! The inlet

pressure is too high for

vacuum.

Select RETRY or ESC icon.

Set Tank Tare Invalid entry. Must be

between XXYY and XXYY.

Tank tare range is either too low or

too high. Select Retry to re-enter

tank tare value or ESC icon.

Slow Charge Charge stalled! Check

connections and valves.

XX.XXXYY of XX.XXXYY

charged.

Check panel valve position and

couplers. Select RETRY or ESC

icon.

Startup System Fault. RTC Fault. System missing date/time

information. Select ESC icon to run

RTC routine.

System Flush Insufcient refrigerant. 6.00kg

required for system ush.

Select ESC icon, then perform tank

ll.

System Flush Pressure too high for ush.

System must be recovered.

Select ESC icon, then perform

recovery.

Tank Fill Source tank is empty. Filled:

XX.XXYY.

Source tank emptied during the tank

ll process. Connect new source

tank, then select RETRY or ESC

icon.

Vacuum The inlet pressure is too

high for vacuum. Recover or

Cancel.

Run a recovery by selecting Recover

or ESC icon to quit.

Vacuum Vacuum Halted! The inlet

pressure is too high for

vacuum.

Select RETRY or ESC icon.

Vacuum Test Test failed! Select RETRY or ESC icon.

Recovery

Refrigerant purity acceptable

(if the refrigerant identier is

present)

Refrigerant analysis test passed:

refrigerant purity acceptable

Loading...

Loading...