10 Climate 5000 – 6720886909 (2018/04)

Indoor Unit Installation

Wall

Indoor Outdoor

5-7mm

Fig. 4.

Mounting plate dimensions

Different models have different mounting plates. In order to ensure that

you have ample room to mount the indoor unit, the diagrams to the

right show different types of mounting plates along with the following

dimensions:

• Width of mounting plate

• Height of mounting plate

• Width of indoor unit relative to plate

• Height of indoor unit relative to plate

• Recommended position of wall hole (both to the left and right of

mounting plate)

• Relative distances between screw holes

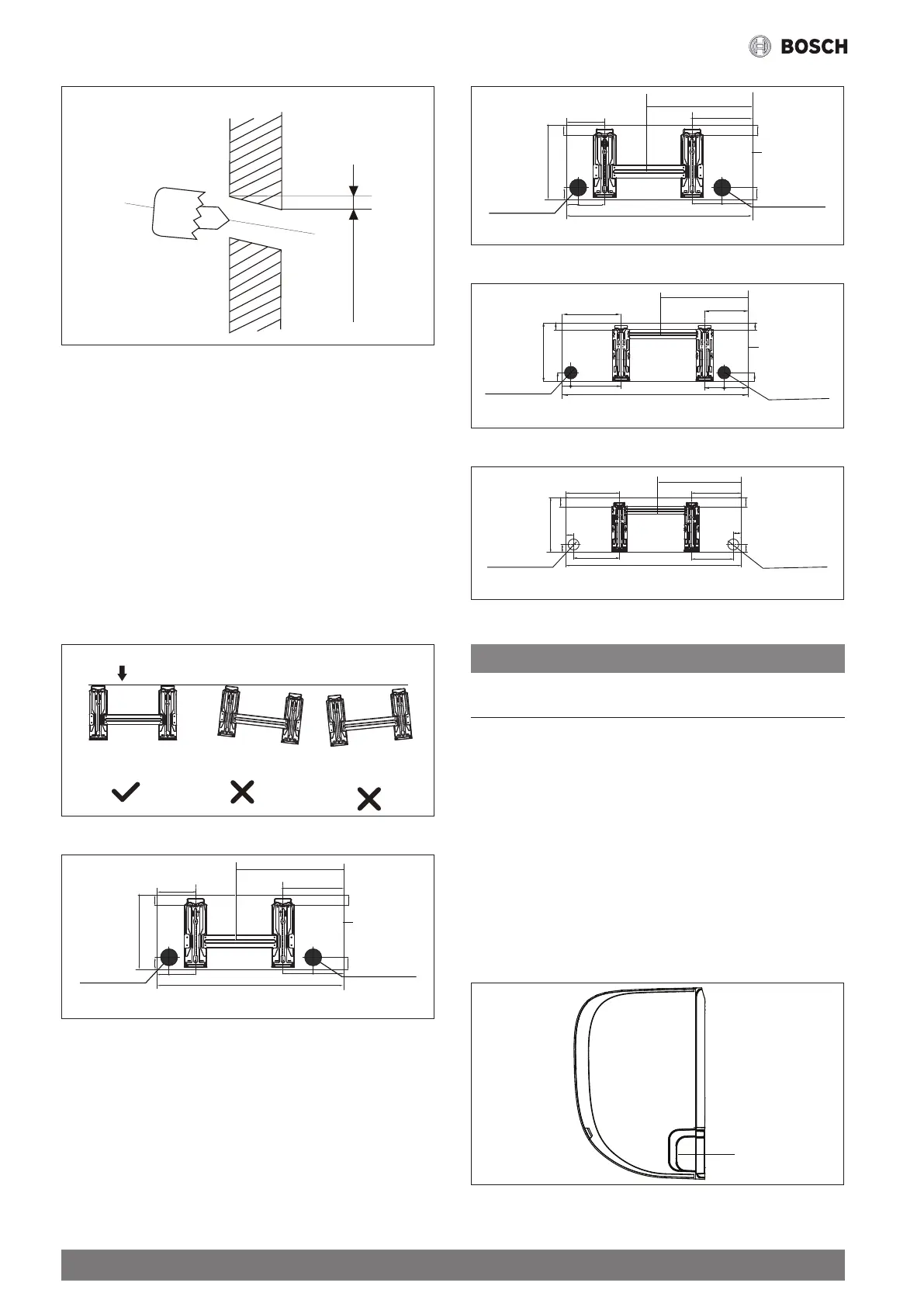

Correct orientation of Mounting Plate

Fig. 5.

Model A

Left rear wall

hole 65mm

Right rear wall

hole 65mm

Indoor unit

outline

398mm

715mm

233.1mm

146.5mm

285mm

45mm 101.6mm 115.6mm

47.1mm

47.1mm

39mm

39mm

117.5mm

Fig. 6.

Model B

Left rear wall

hole 65mm

Right rear wall

hole 65mm

Indoor unit

outline

398mm

805mm

241mm

228.5mm

285mm

45mm 183.6mm 123.6mm

47.1mm

47.1mm

39mm

39mm

117.5mm

Fig. 7.

Model C

Left rear wall

hole 65mm

Right rear wall

hole 65mm

Indoor unit

outline

439mm

958.3mm

224.2mm

228.5mm

285mm

45mm

259.1mm

100.6mm

47mm

47.5mm

36.7mm

36.6mm

123.7mm

Fig. 8.

Model D

Left rear wall

hole 65mm

Right rear wall

hole 65mm

506mm

1037.6mm

291mm

316.7mm

324.9mm

47mm

47mm

55mm

55mm

246mm271.7mm

Fig. 9.

NOTE

When the gas side connective pipe is Ø16mm or more, the wall hole

should be 90mm.

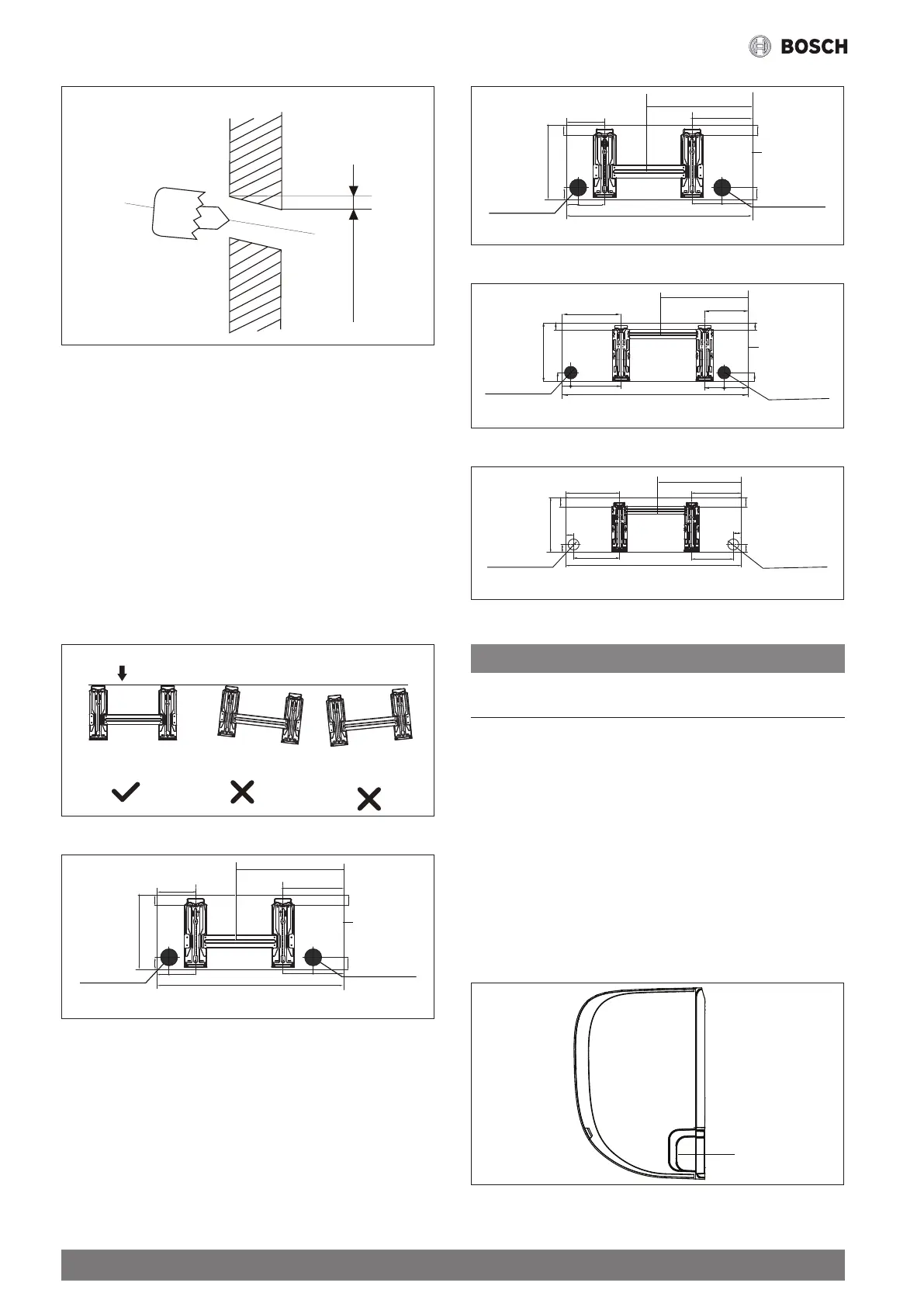

1.4 Step 4: Prepare refrigerant piping

The refrigerant piping is inside an insulating sleeve attached to the back

of the unit. You must prepare the piping before passing it through the

hole in the wall. Refer to the Refrigerant Piping Connection section

of this manual for detailed instructions on pipe flaring and flare torque

requirements, technique, etc.

1. Based on the position of the wall hole relative to the mounting plate,

choose the side from which the piping will exit the unit.

2. If the wall hole is behind the unit, keep the knock-out panel in place.

If the wall hole is to the side of the indoor unit, remove the plastic

knock-out panel from that side of the unit. (See Fig. 10). This will

create a slot through which your piping can exit the unit. Use needle

nose pliers if the plastic panel is too difficult to remove by hand.

Knock-out Panel

Fig. 10.

Loading...

Loading...