Technical information

Compress 3000 AWES – 6720892204 (2020/06)

32

11.3.6 EVU/SG wiring diagram for the indoor unit with an

integrated electric booster heater

11.3.7 Photovoltaic

Since there are only two external inputs for the energy supplier and PV,

these cannot be used at the same time.

PV connection to external input 1 or 4.

The heat pump is able to process a control signal of a PV system.

If the PV system has sufficient current for operating the heat pump, it can

communicate this information to the heat pump in the form of a start

command via a control cable. The control cable must be connected to

one of the available external connections. The selected external

connection must be configured in the control unit for the PV function.

The heating system must have a buffer cylinder and only heating circuits

with a mixer in order for a start command to be effective. A start

command causes the buffer cylinder to be charged up to the maximum

temperature achievable by the heat pump. However, it can only be

charged when the temperature in the buffer cylinder is below the

maximum temperature. Otherwise, the heat pump remains off.

11.4 Kabelplan

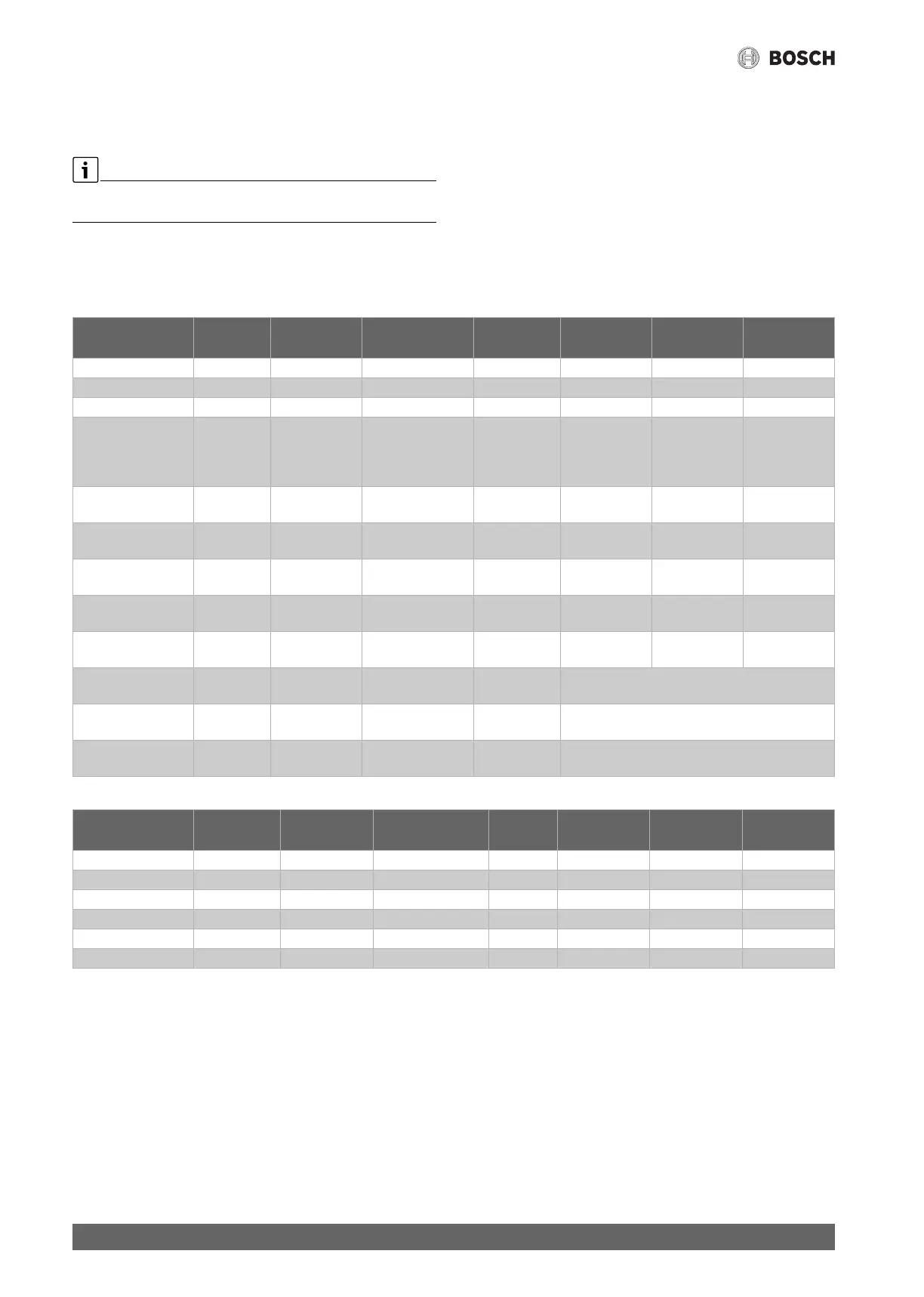

Table 11 Connections in indoor units IDU AWE/AWM/AWMS and AWB

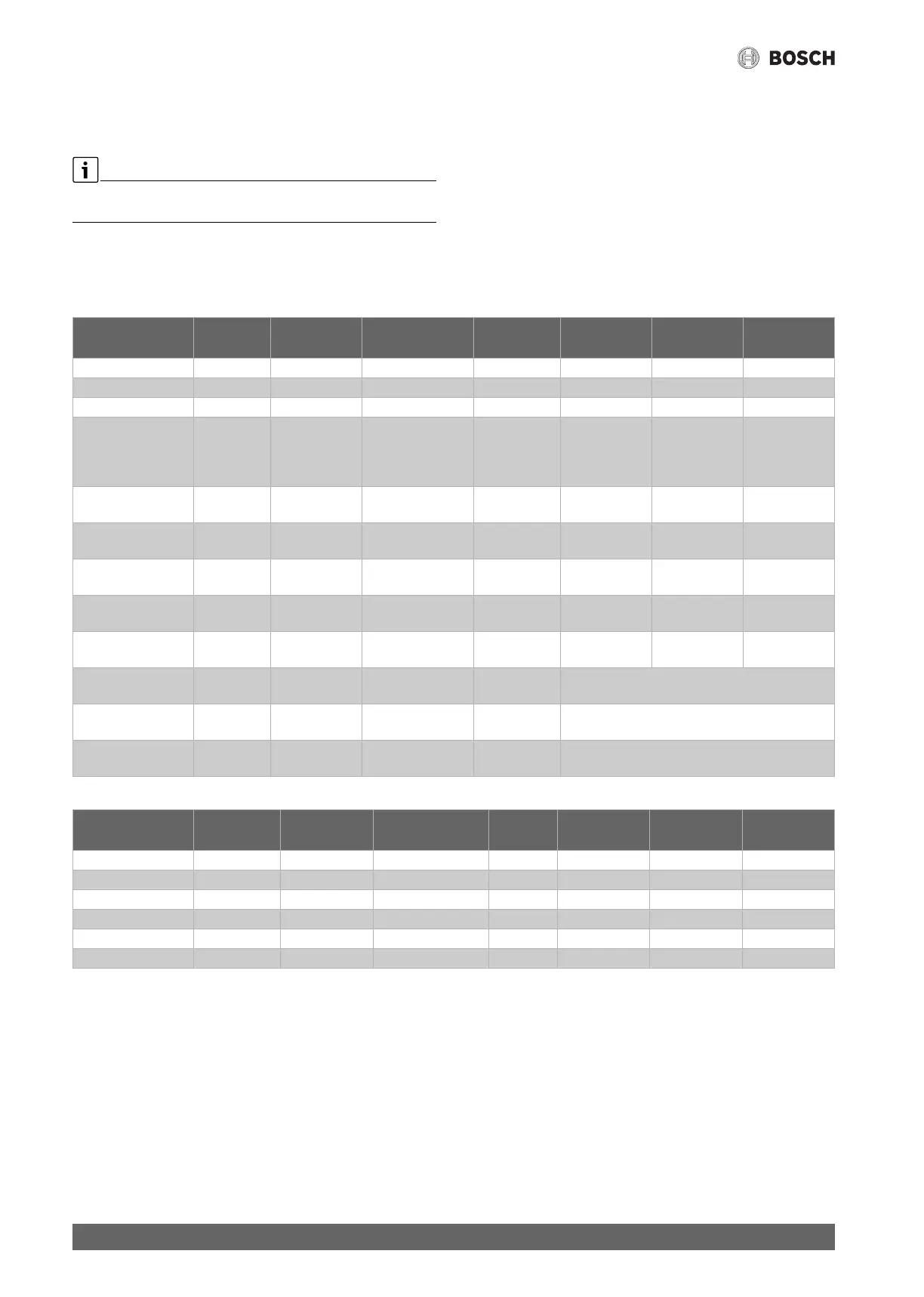

Table 12 Cable plan sensor

11.5 Measurements from temperature sensors

Designation min. cross-

section

type of cabel max. length connected at: connection

terminal:

Power source

3-way valve VW1 3 x 1,5mm² cable integrated Indoor unit 53 / 54 / N IDU

Pump 1. HC PC1 3 x 1,5mm² H05VVF Indoor unit 52 / N / PE

DHW pump PW2 3 x 1,5mm² H05VVF 58 / N / PE

Signal cable IDU - ODU CAN-BUS 2 x 2 x 0,75mm

2

LIYCY (TP) 30m Can High 31(H)

Can Low 32(L)

12V not

connected

2-wire

connection,

shielding in both

ends

Power supply IDU AWE/

AWM/AWMS

5 x 2,5mm² NYY Indoor unit sub-distribution

3 x C16

Power supply IDU AWB 3 x 1,5mm² NYY Indoor unit L / N / PE sub-distribution

1x C16

Heating cable 3 x 1,5mm² NYY 3m Indoor unit 56 / N / (HC /

HC)

IDU / HC / HC

EMS - Module MM100,

MS100..

0,5mm² J-Y (ST)Y 2 x 2 x 0,6 100m Indoor unit 19 / 20

0-10V control boiler EM0 2 x 2 x 0,75mm

2

LIYCY (TP) Indoor unit

(IDU AWB)

38 / 39

PV-Function 0,4mm² J-Y (ST)Y 2 x 2 x 0,6 From inverter on terminal I1 or I4 in IDU,

EVU-block or Smart Grid

Smart Grid 0,4mm² J-Y (ST)Y 2 x 2 x 0,6 From load management controller on terminal I4,

connection 49, 50 in IDU

EVU-block 3 x 1,5mm² H05VVF From load management controller on terminal I1,

connection 13, 14 in IDU

Sensor Designation min. cross-

section

type of cabel max.

length

connected at: connection

terminal:

Power source

Outdoor T1 0,5 mm

2

J-Y (ST)Y 2 x 2 x 0,6 Indoor unit 3 / 4

Flow T0 0,5 mm

2

J-Y (ST)Y 2 x 2 x 0,6 Indoor unit 1 / 2

Hot water (DHW) TW1 0,5 mm

2

J-Y (ST)Y 2 x 2 x 0,6 Indoor unit 5 / 6

Dew sensor MK2 (max. 5x) 0,5 mm

2

cable integrated Indoor unit 34 / 35

Mixed heating circuit TC1 0,5 mm

2

J-Y (ST)Y 2 x 2 x 0,6 100m MM100 1 / 2

Pool temperature TC1 0,5 mm

2

J-Y (ST)Y 2 x 2 x 0,6 100m MP100 1 / 2

Loading...

Loading...