21

1

2

Alternator Testing

The following alternator test procedures were

developed using the Fluke® Digital Multimeter.

When performing alternator tests with the

UNI-T® Digital Multimeter, refer to the operating

manual supplied with that meter for the proper

procedure.

All test values will be the same regardless the

meter used.

NOTE: Before testing alternator output, use an

accurate tachometer to temporarily adjust the

engine speed to the RPM specified in the test

instructions.

When testing alternators, perform the tests in the

following sequence:

1. Test alternator output.

2. Test diode(s) or regulator-rectifier (if

equipped).

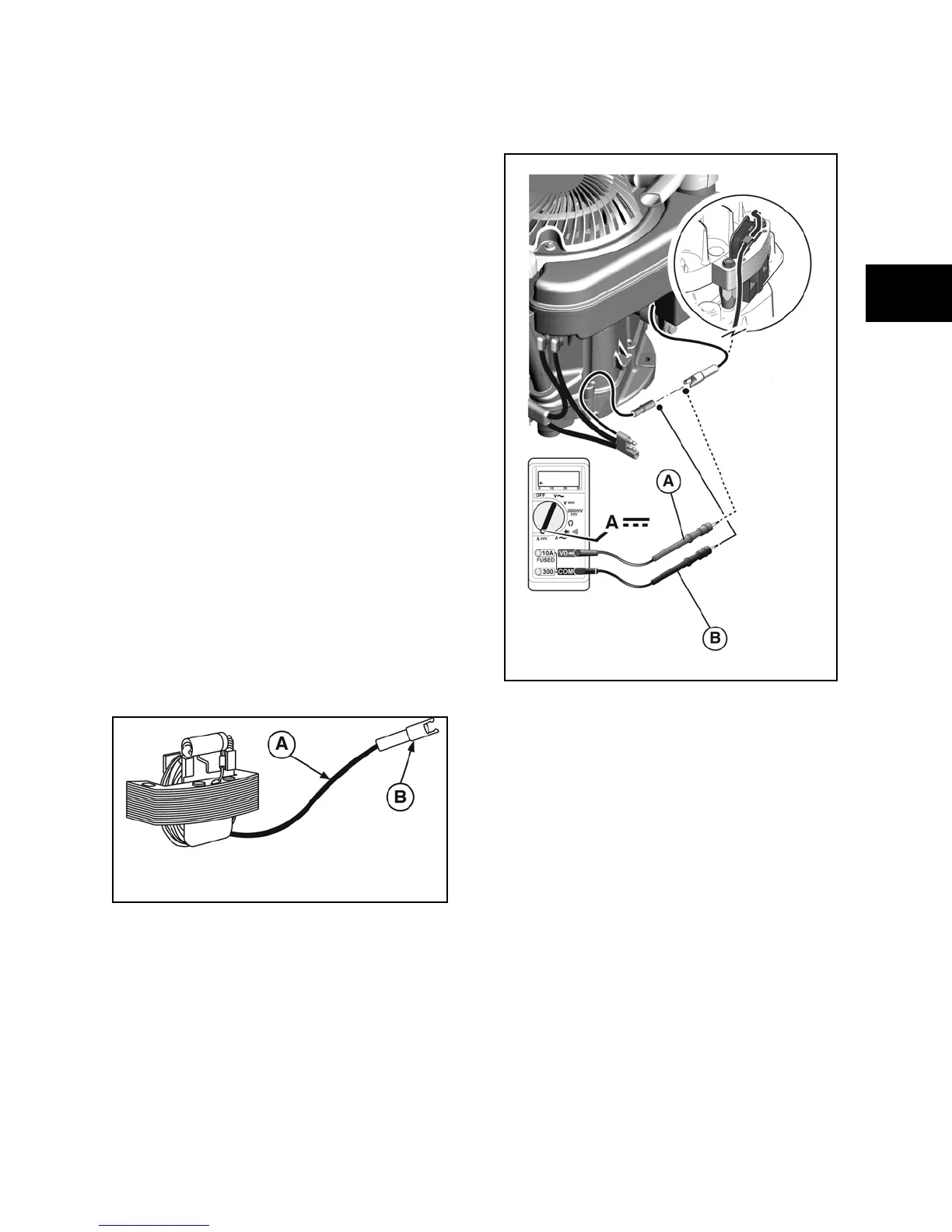

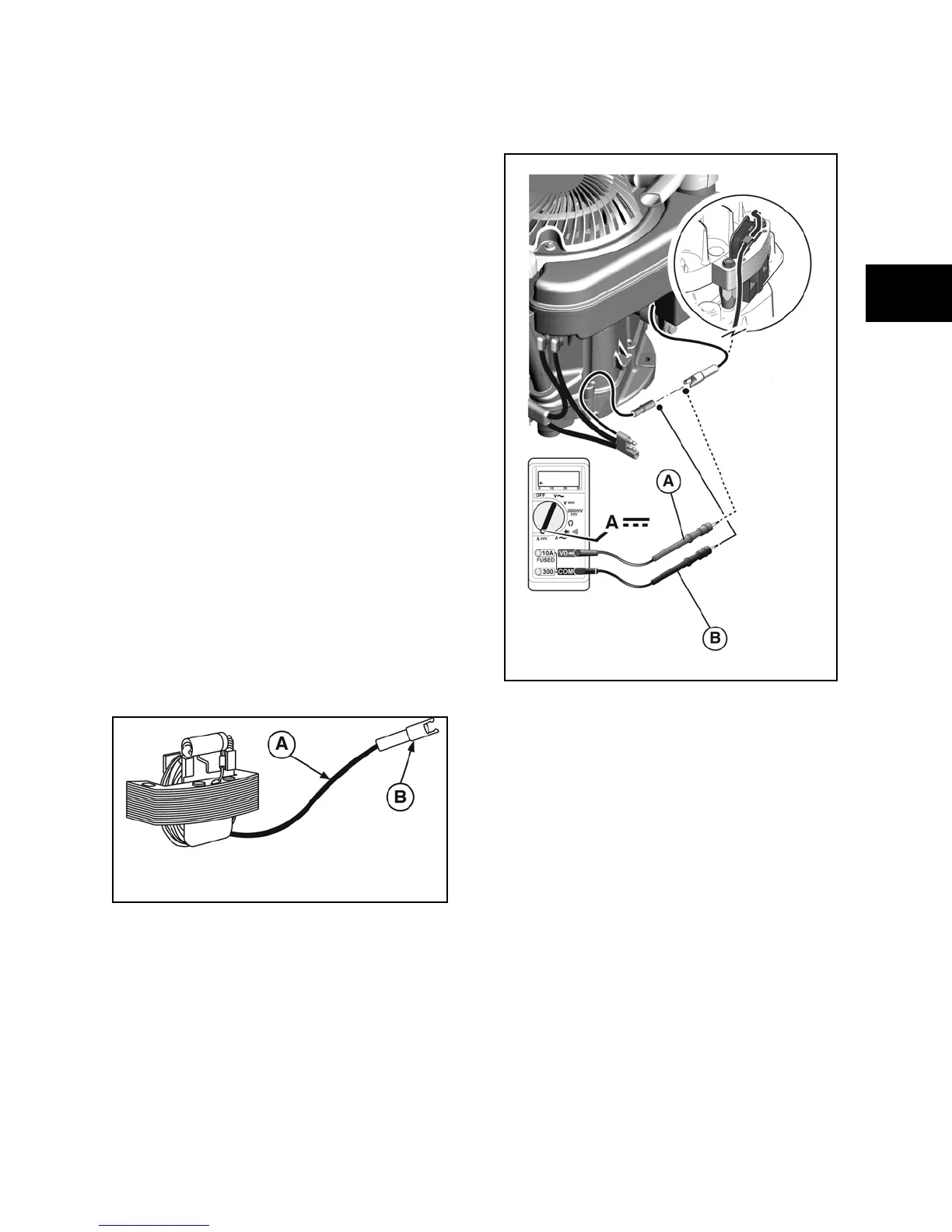

The 0.5 Amp, DC alternator (Figure 2-6) is

designed to operate as an integral part of the

engine and is separate from the starting and

ignition system. It is intended to provide DC

charging current for a 12 Volt battery.

• Unregulated

• 0.5 Amps DC for charging battery

• One black lead (A) from stator

• White connector (B) output lead

Figure 2 - 6

1. Disconnect charging lead to battery at

white connector.

2. Insert RED test lead into 10 Amp

receptacle in meter.

3. Insert BLACK test lead into COM

receptacle in meter.

4. Rotate selector to DC Amps position.

5. Attach RED test clip to output lead (A,

Figure 2-7).

6. Attach BLACK test clip to charging lead

(B).

Figure 2 - 7

7. Install tachometer, then start and run

engine at 2800 RPM. Meter should display

no less than 0.5 Amp DC.

8. If low or no output, check alternator air

gap. Adjust to value listed in Section 12 -

Engine Specifications.

9. If alternator air gap is within specification

and there is still low or no output, replace

alternator.

Loading...

Loading...