56

4

9

Inspect Sump

1. Remove oil seal and discard.

2. Visually inspect sump for cracks, stripped

threads, and wear in bearing surfaces. If

damage is found, replace the sump.

Cleaning Sump

1. Wash the sump thoroughly with kerosene

or other commercial solvent.

2. Wash sump again using a stiff brush with

soap and hot water.

3. Rinse sump thoroughly with hot running

water.

4. Repeat washing and rinsing until all traces

of oil sludge are gone.

Main Bearings

Plain Bearings

Plain (or machined) bearings are not repairable.

If a plain bearing is scored or worn beyond reject

its size, the cylinder or cover/sump must be

replaced.

DP™Bearings

DP™ bearings are not repairable. If a DP™

bearing is scored or worn beyond its reject size,

the cylinder or cover/sump must be replaced.

NOTE: Standard and reject sizes for the main

bearings are listed in Section 12 - Engine

Specifications.

Oil Seals

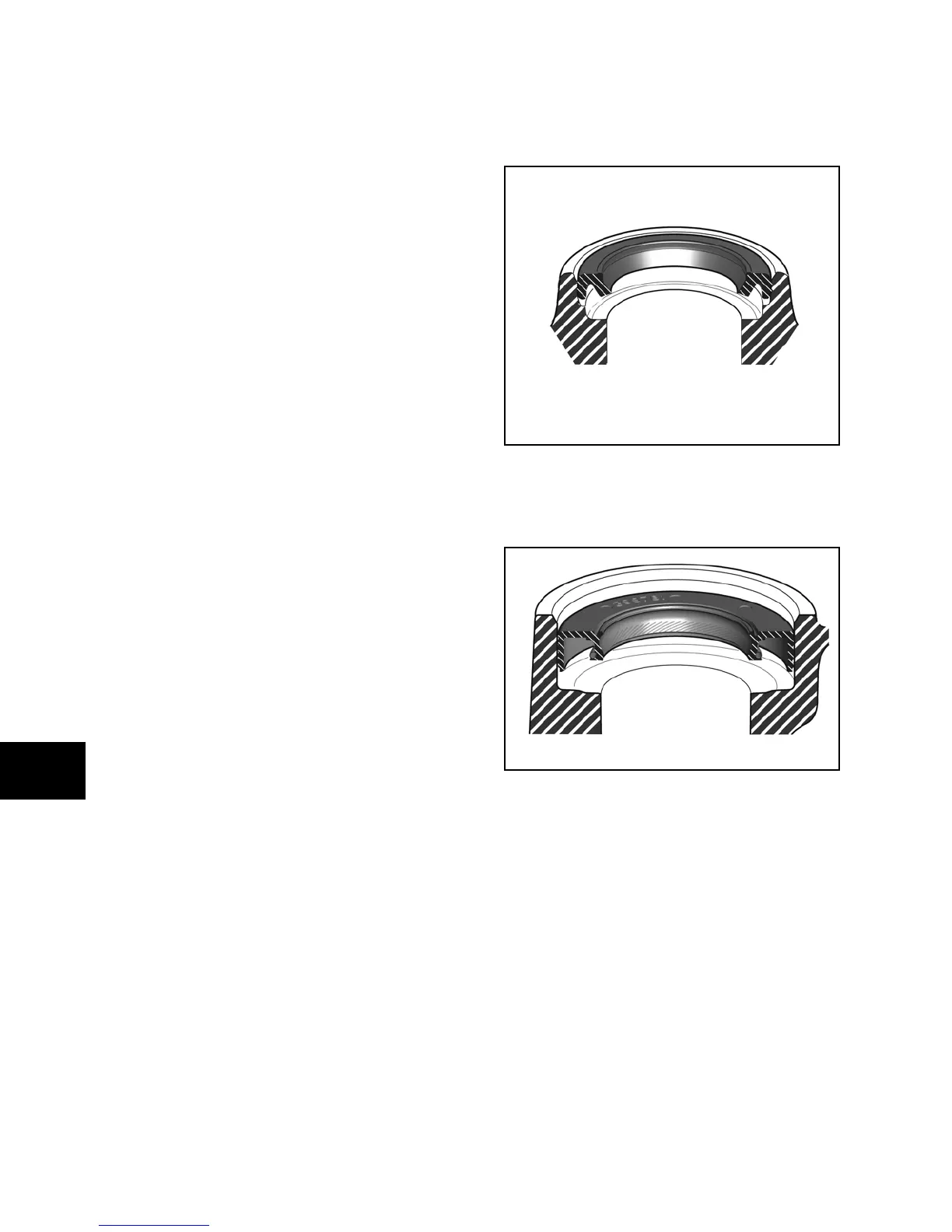

Cylinder

Press in new oil seal to a depth of 0.156 - 0.206

in. (3 - 5mm) (Figure 9-2).

Figure 9 - 2

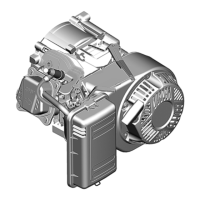

Sump

Press in new oil seal to a depth of 0.157 - 0.276

in. (4 - 7 mm) (Figure 9-3).

Figure 9 - 3

Loading...

Loading...