4 - 14

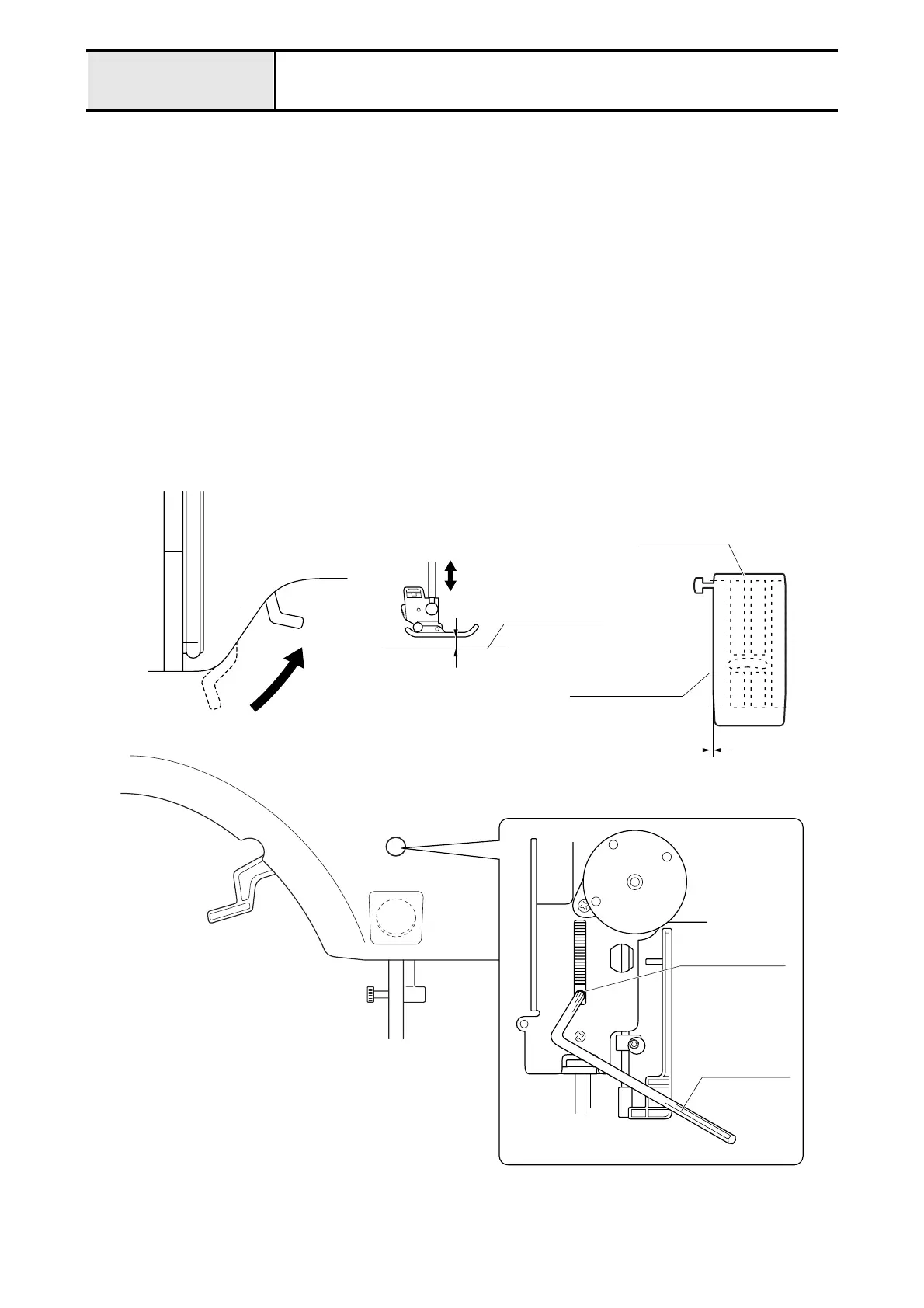

Adjustment Presser bar height and parallelism

[Adjustment standard]

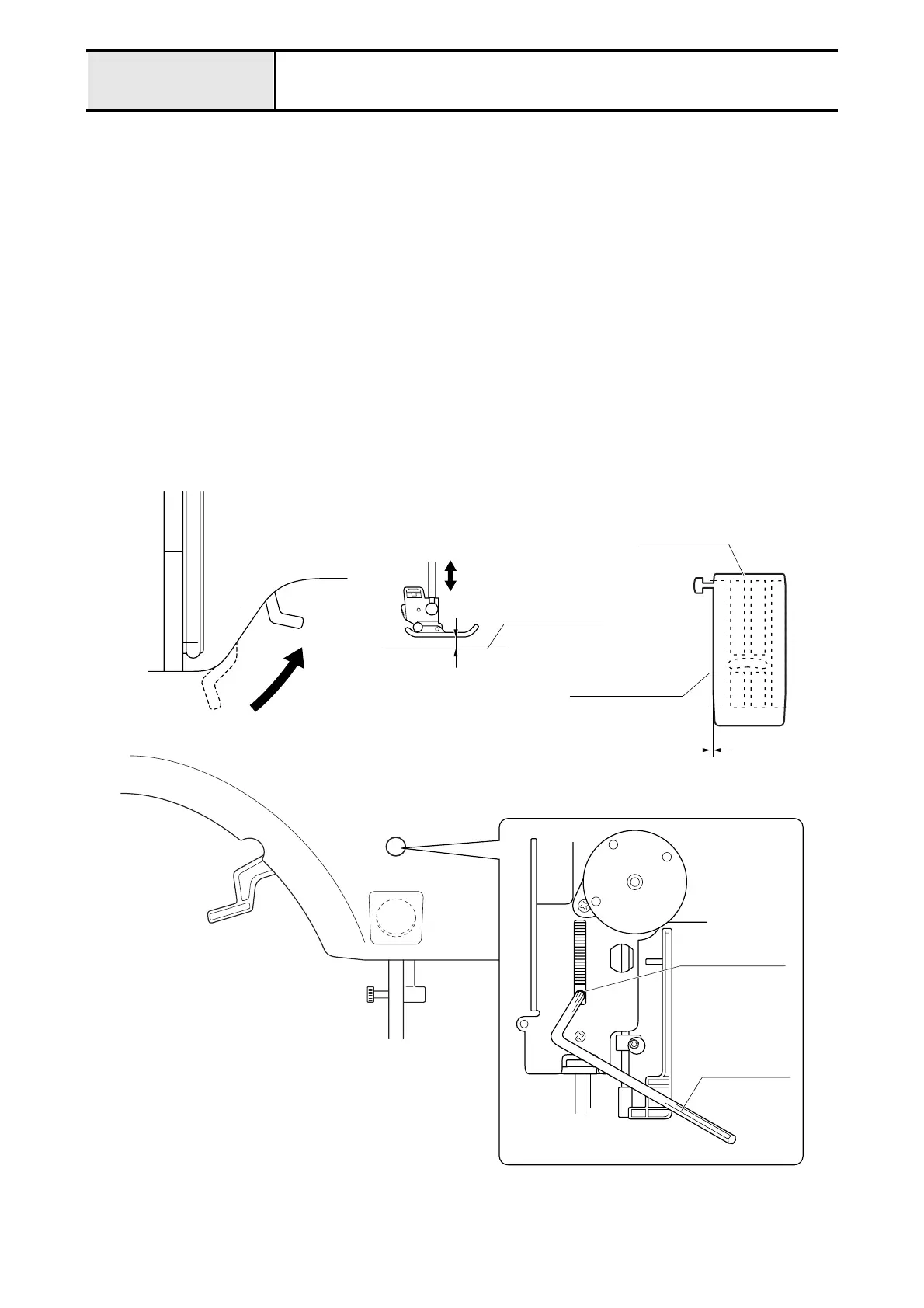

• The clearance between the needle plate A and bottom surface of the presser foot must be 6.0 to 6.5mm.

• The presser foot must parallel with the feed dog hole of needle plate A.

[Adjustment procedure]

1. Attach the J foot.

2. Raise the presser lever.

3. Turn the pulley by hand and down the feed dog lower than the needle plate A.

4. Loosen the screw (screw stud M5) of the presser bar clamp assy. with the hex wrench (2.5mm).

5. Move the needle presser bar up and down, to adjust the clearance between the needle plate A and the bottom

surface of the presser foot to 6.0 to 6.5mm.

6. Tighten the screw (screw stud M5) of the presser bar clamp assy..

*Key point

•

Check the presser foot parallel with the feed dog hole of needle plate A after adjusting presser bar

height. (to prevent slanting during overcast stitch and damage to the needle.)

Presser foot

Feed dog hole

(Needle plate A)

Parallel

Screw stud M5

Hex wrench

(2.5mm)

Top face of

needle plate A

6.0 - 6.5mm

Loading...

Loading...