26

ENG

“EVD ice” +0300038EN - rel. 1.1 - 23.04.2018

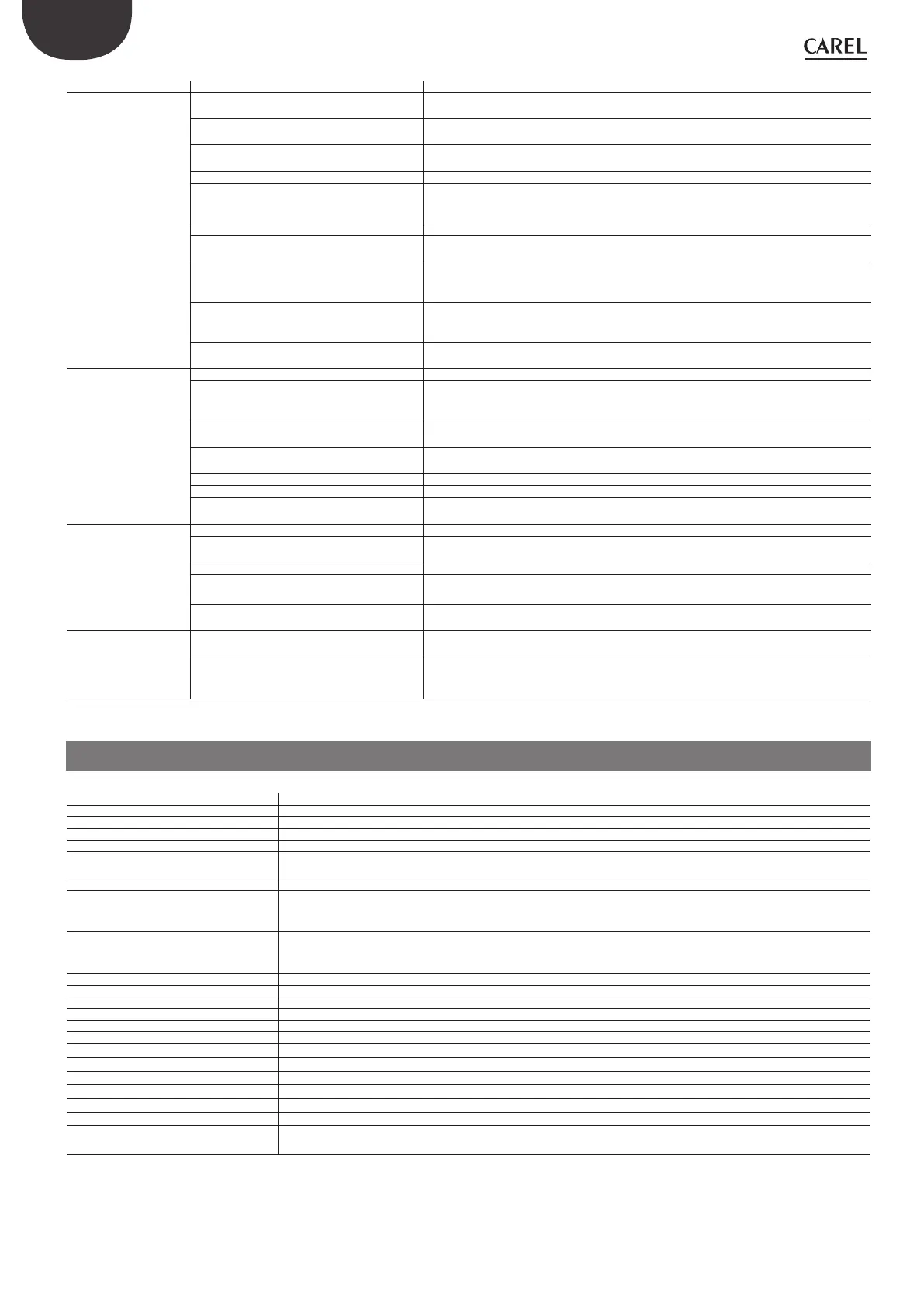

11. TECHNICAL SPECIFICATIONS

Power supply 115…230 Vac (+10/-15%) 50/60 Hz

Power input max (W) 15

Emergency power supply 13 Vdc +/-10% (

If it is installed the optional Ultracap module for EVD ice, for EVDM011R1*/EVDM011R2*)

Driver Unipolar valve

Valve connection 6-wire cable AWG 18/22 type, Lmax=1m

Digital input connection digital input 230 V optoisolated. Closing current: 10 mA

Lmax=10m for residential/industrial environments, 2m for domestic environments

Probe

S1 ratiometric pressure probe (0…5 V):

Resolution 0,1 % fs

Measurement error: 2% fs max; 1% typical

S2 low temperature NTC:

10kΩ a 25°C, -50T90°C

Measurement error: 1°C in the range -50T50°C; 3°C in the range +50T90°C

RS485 serial connection Modbus, Lmax=500m, shielded cable, earth connection in both side of shielded-cable

Assembly with screw

Dimensions LxHxW= 93 x 230 x 41 mm

Operating conditions -30T40°C (don’t use EVDIS* lower than -20°C); <90% U.R. non-condensing

Storage conditions -35T60°C (don’t store EVDIS* lower than -30°C), humidity 90% U.R. non-condensing

Index of protection IP65/IP67

Environmental pollution 2

Temperature for glow wire test

850°C

Immunity against voltage surges Category II

Class of insulation II

Software class and structure A

Conformity

Electrical safety: EN 60730-1, UL 60730-1, UL 60730-2-9

Electromagnetic compatibility: EN 61000-6-1, EN 61000-6-2, EN 61000-6-3, EN 61000-6-4

EN61000-3-2, EN55014-1, EN61000-3-3

Tab. 11.a

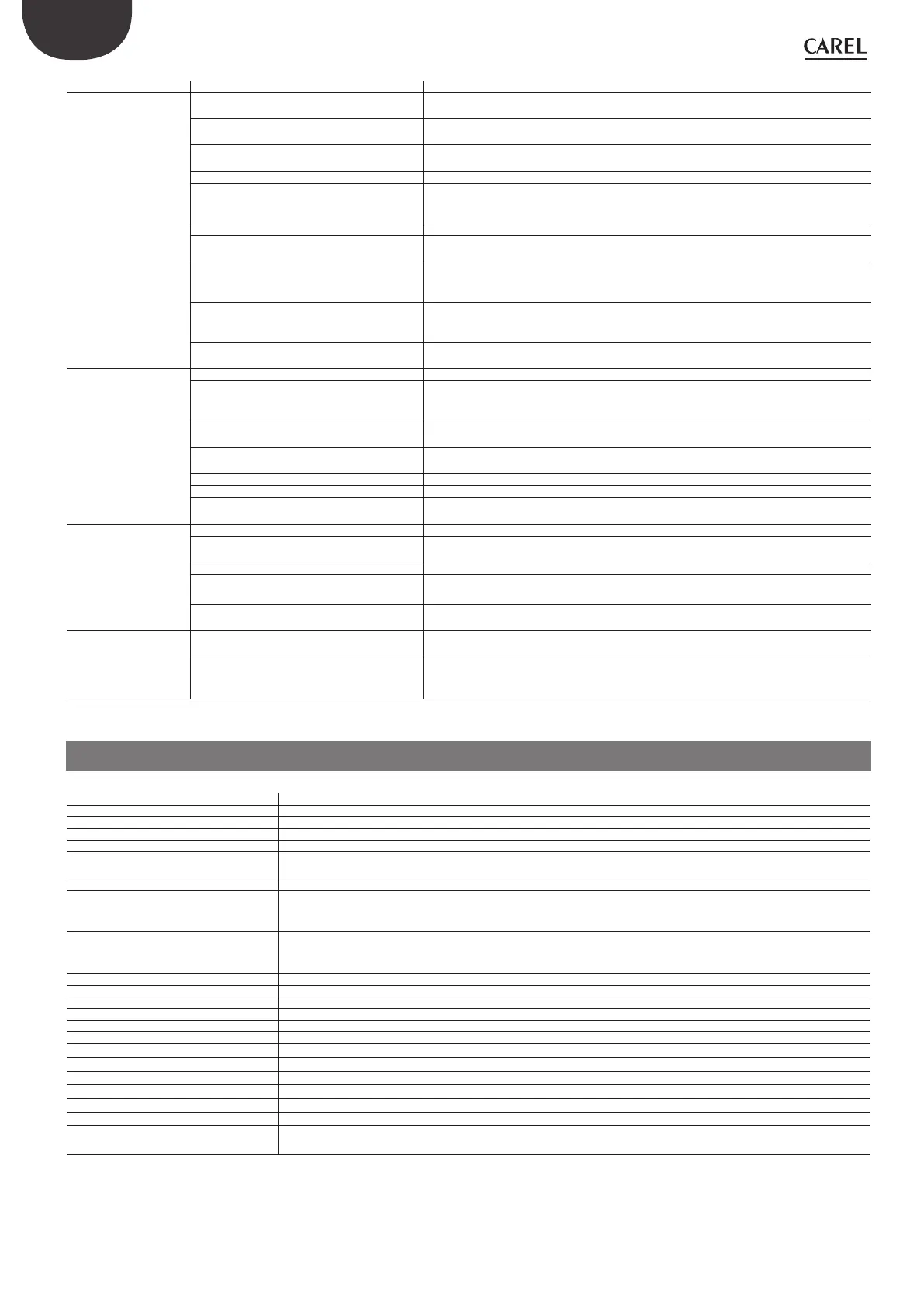

PROBLEM CAUSE SOLUTION

In the start-up phase the

low pressure protection

is activated (only for self-

contained units)

The “Valve opening at start-up” parameter is set

too low

Check the calculation in reference to the ratio between the rated cooling capacity of the evapo-

rator and the capacity of the valve; if necessary increase the value.

The driver in RS485 network does not start control

and the valve remains closed

Check the serial connection. Check that the pCO application connected to the driver (where fea-

tured) correctly manages the driver start signal. Check that the driver is NOT in stand-alone mode.

The driver in stand-alone conguration does not

start control and the valve remains closed

Check the connection of the digital input. Check that when the control signal is sent that the

input is closed correctly. Check that the driver is in stand-alone mode.

LOP protection disabled Set a LOP integration time greater than 0 s.

LOP protection ineective Make sure that the LOP protection threshold is at the required saturated evaporation temperature

(between the rated evaporation temperature of the unit and the corresponding temperature at

the calibration of the low pressure switch) and decrease the value of the LOP integration time.

Solenoid blocked Check that the solenoid opens correctly, check the electrical connections.

Insucient refrigerant Check that there are no bubbles in the sight glass upstream of the expansion valve. Check that

the subcooling is suitable (greater than 5 °C); otherwise charge the circuit.

The valve is connected incorrectly (rotates in re-

verse) and is open

Check the movement of the valve by placing it in manual control and closing or opening it com-

pletely. One complete opening must bring a decrease in the superheat and vice-versa. If the

movement is reversed, check the electrical connections.

Stator broken or connected incorrectly Disconnect the stator from the valve and the cable and measure the resistance of the windings

using an ordinary tester. The resistance of both should be around 36 ohms. Otherwise replace

the stator. Finally, check the electrical connections of the cable to the driver (see paragraph 5.1).

Valve stuck closed Use manual control after start-up to completely open the valve. If the superheat remains high,

check the electrical connections and/or replace the valve.

The unit switches o due

to low pressure during

control (only for self-con-

tained units)

LOP protection disabled Set a LOP integration time greater than 0 s.

LOP protection ineective Make sure that the LOP protection threshold is at the required saturated evaporation temperature

(between the rated evaporation temperature of the unit and the corresponding temperature at

the calibration of the low pressure switch) and decrease the value of the LOP integration time.

Solenoid blocked Check that the solenoid opens correctly, check the electrical connections and the operation of

the control relay.

Insucient refrigerant Check that there are no bubbles of air in the liquid indicator upstream of the expansion valve.

Check that the subcooling is suitable (greater than 5 °C); otherwise charge the circuit.

The valve is signicantly undersized Replace the valve with a larger equivalent.

Stator broken Enable the manual positioning and check the opening and closure of the valve.

Valve stuck closed Use manual control after start-up to completely open the valve. If the superheat remains high,

replace the valve body.

The cabinet does not

reach the set tempera-

ture, despite the value

being opened to the ma-

ximum (for multiplexed

cabinets only)

Solenoid blocked Check that the solenoid opens correctly, check the electrical connections and the operation of the relay.

Insucient refrigerant Check that there are no bubbles of air in the liquid indicator upstream of the expansion valve.

Check that the subcooling is suitable (greater than 5 °C); otherwise charge the circuit.

The valve is signicantly undersized Replace the valve with a larger equivalent.

Stator broken Enable the manual positioning and check the opening and closure of the valve.

Valve stuck closed Use manual control after start-up to completely open the valve. If the superheat remains high,

replace the valve body.

The cabinet does not

reach the set temperatu-

re, and the position of the

valve is always 0 (for mul-

tiplexed cabinets only)

The driver in RS485 network does not start control

and the valve remains closed

Check the network connections. Check that the pCO application connected to the driver (where fe-

atured) correctly manages the driver start signal. Check that the driver is NOT in stand-alone mode.

The driver in stand-alone conguration does not

start control and the valve remains closed

Check the connection of the digital input. Check that when the control signal is sent that the

input is closed correctly. Check that the driver is in stand-alone mode.

Tab. 10.a

Loading...

Loading...