BEFORE INITIAL START-UP

Job Data Required

• list of applicable design temperatures and pressures (prod-

uct data submittal)

• machine certified drawings

• starting equipment details and wiring diagrams

• diagrams and instructions for special controls or options

• 17/19EX Installation Instructions

• pumpout unit instructions

Equipment Required

• mechanic’s tools (refrigeration)

• digital volt-ohmmeter (DVM)

• clamp-on ammeter

• electronic leak detector

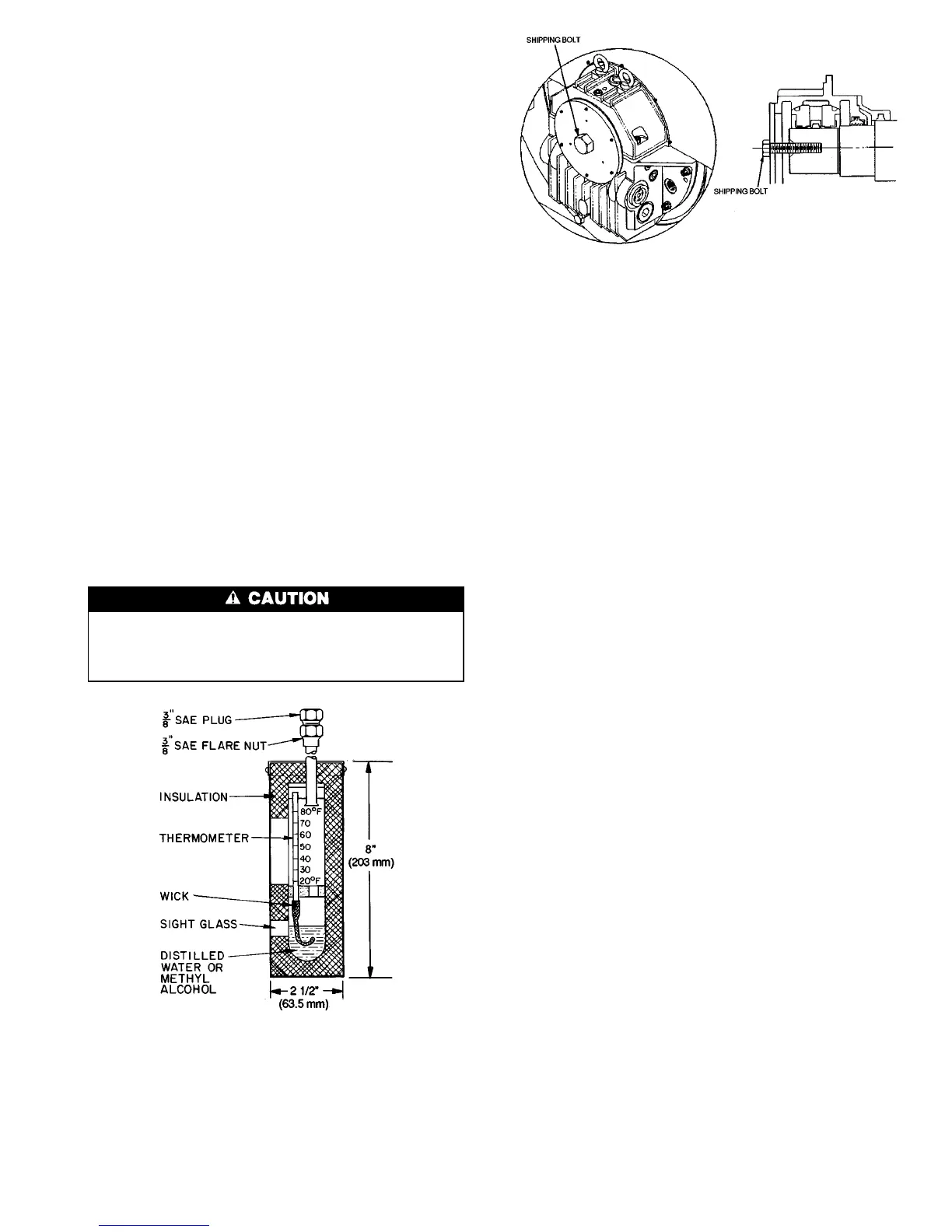

• absolute pressure manometer or wet-bulb vacuum indica-

tor (Fig. 26)

• 500 v insulation tester (megohmmeter) for compressor mo-

tors with nameplate voltage of 600 v or less, or a

5000-v insulation tester for compressor motor rated above

600 v

Using the Utility Vessel and Pumpout System

—

Refer to Pumpout and Refrigerant Transfer Procedures

section, page 64 for: pumpout system preparation, refriger-

ant transfer, and machine evacuation.

Remove Shipping Packaging — Remove any pack-

aging material from the control center, power panel, guide

vane actuator, motor cooling and oil reclaim solenoids, mo-

tor and bearing temperature sensor covers, and the factory-

mounted starter.

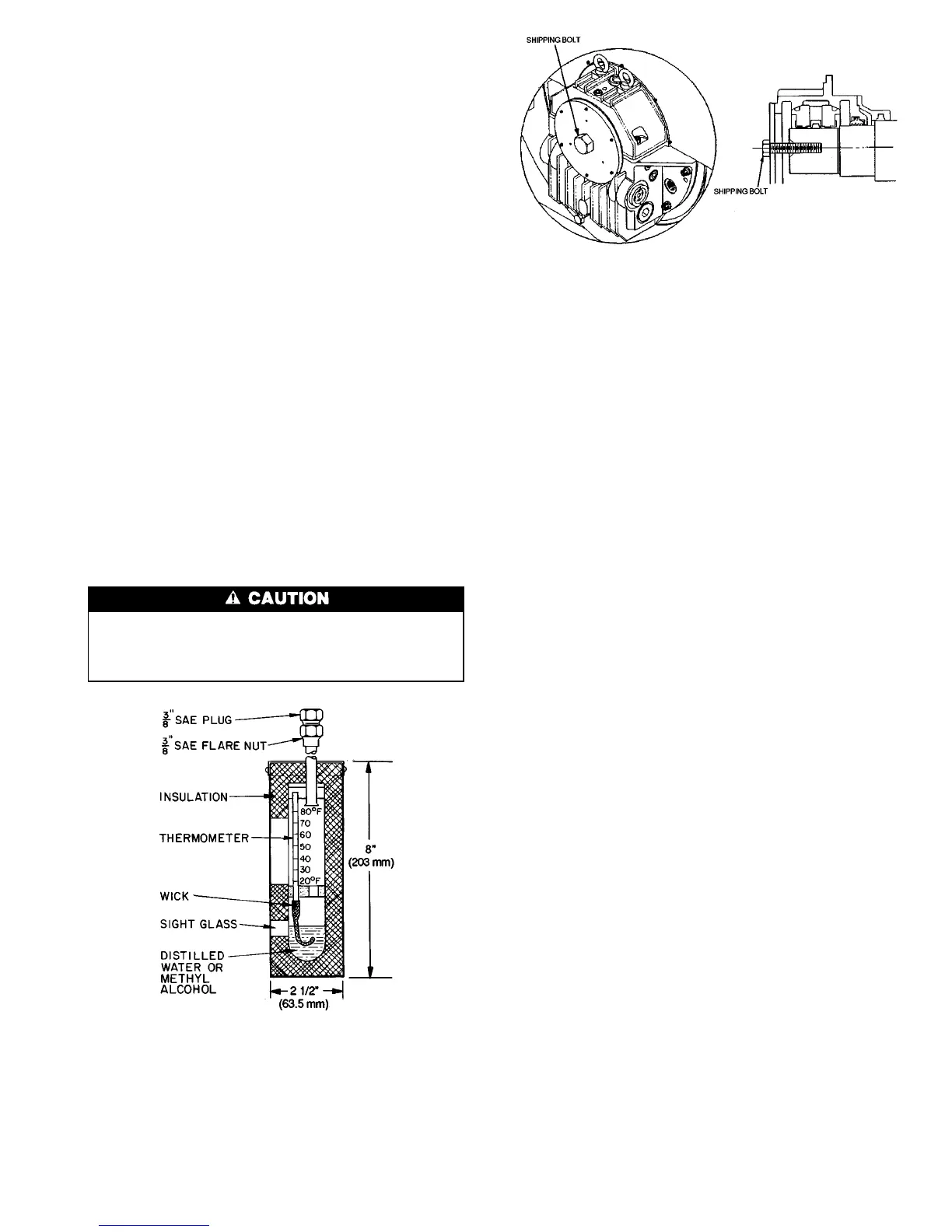

OPEN DRIVE MOTOR

The motor may be provided with a shipping brace or

shipping bolt (normally painted yellow) to prevent shaft

movement during transit. It must be removed prior to

operation. See Fig. 27.

The motor should be inspected for any temporary, yellow

caution tags whose legends convey information concerning

actions necessary before the motor can be safely operated.

Any slushing compound on the shaft or other parts must be

removed using a petroleum type solvent and observing proper

safety precautions.

NOTE: If the motor utilized a shipping bolt for restraining

the rotor, the Westinghouse logo must be installed over the

hole in the endcover. The logo, the gasket, and hardware can

be found with the parts that have been shipped loose. (Usu-

ally these are packed inside of the main power lead box.)

Open-Drive Motor Electrical Connection — All

interconnecting wiring for controls and grounding should be

in strict accordance with both the National Electrical Code

and any local requirements.

The main lead box furnished with the motor has been sized

to provide adequate space for the make-up of the connec-

tions between the motor lead cables and the incoming power

cables. The bolted joints between the motor lead and the power

cables must be made and insulated in a workman-like man-

ner following the best trade practices.

Fabricated motors are provided with 2 stainless steel ground-

ing pads drilled and tapped with the NEMA 2-hole pattern

(two

1

⁄

2

-13 tapped holes on 1

3

⁄

4

in. centers). Fan cooled cast

frames are provided with a special grounding bolt. The mo-

tor should be grounded by a proper connection to the elec-

trical system ground.

The rotation direction of the motor will be as shown by

either a nameplate on the motor or the certified drawing. The

required phase rotation of the incoming power for this motor

rotation may also be stated. If either is unknown, the correct

sequence can be determined in the following manner: While

the motor is uncoupled from the load, start the motor and

observe the direction of rotation. Allow the motor to achieve

full speed before disconnecting it from the power source.

Refer to Open-Drive Motor Pre-Start Checks (page 53) for

information concerning initial start-up. If resulting rotation

is incorrect, it can be reversed by interchanging any 2 in-

coming cables.

Fig. 27 — Shipping Bolt on Open Drive Motor

Fig. 26 — Typical Wet-Bulb Type

Vacuum Indicator

47

Loading...

Loading...