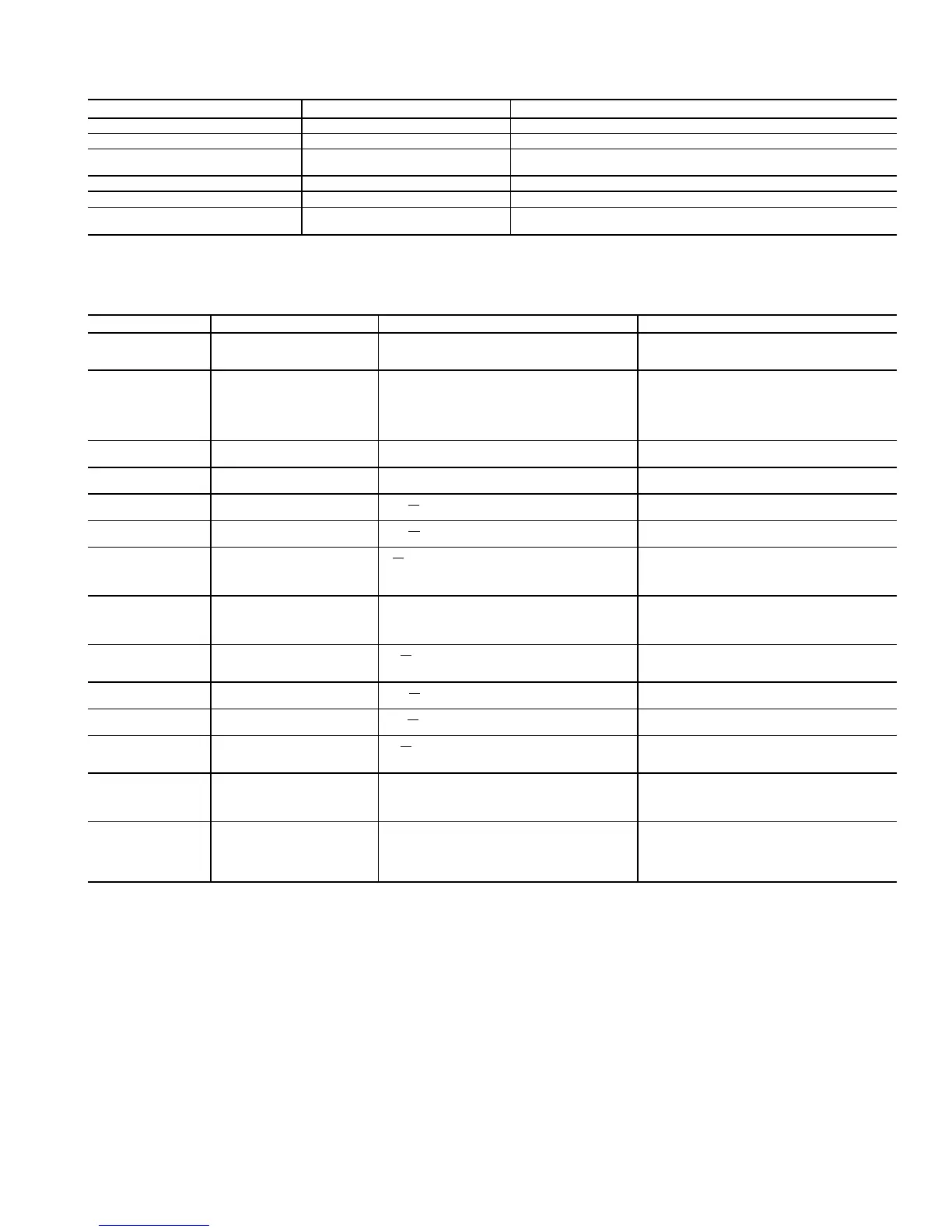

Table 8 — LID Primary and Secondary Messages and Custom Alarm/Alert Messages

with Troubleshooting Guides (cont)

E. NORMAL OR AUTO.-RESTART

PRIMARY MESSAGE SECONDARY MESSAGE PROBABLE CAUSE/REMEDY

STARTUP IN PROGRESS OCCUPIED MODE Machine starting. Time schedule is occupied.

STARTUP IN PROGRESS REMOTE CONTACT CLOSED Machine starting. Remote contacts are closed.

STARTUP IN PROGRESS START COMMAND IN EFFECT

Machine starting. Chiller START/STOP on Status01 manually forced

to start.

AUTORESTART IN PROGRESS OCCUPIED MODE Machine starting. Time schedule is occupied.

AUTORESTART IN PROGRESS REMOTE CONTACT CLOSED Machine starting. Remote contacts are closed.

AUTORESTART IN PROGRESS START COMMAND IN EFFECT

Machine starting. Chiller START/STOP on Status01 manually forced

to start.

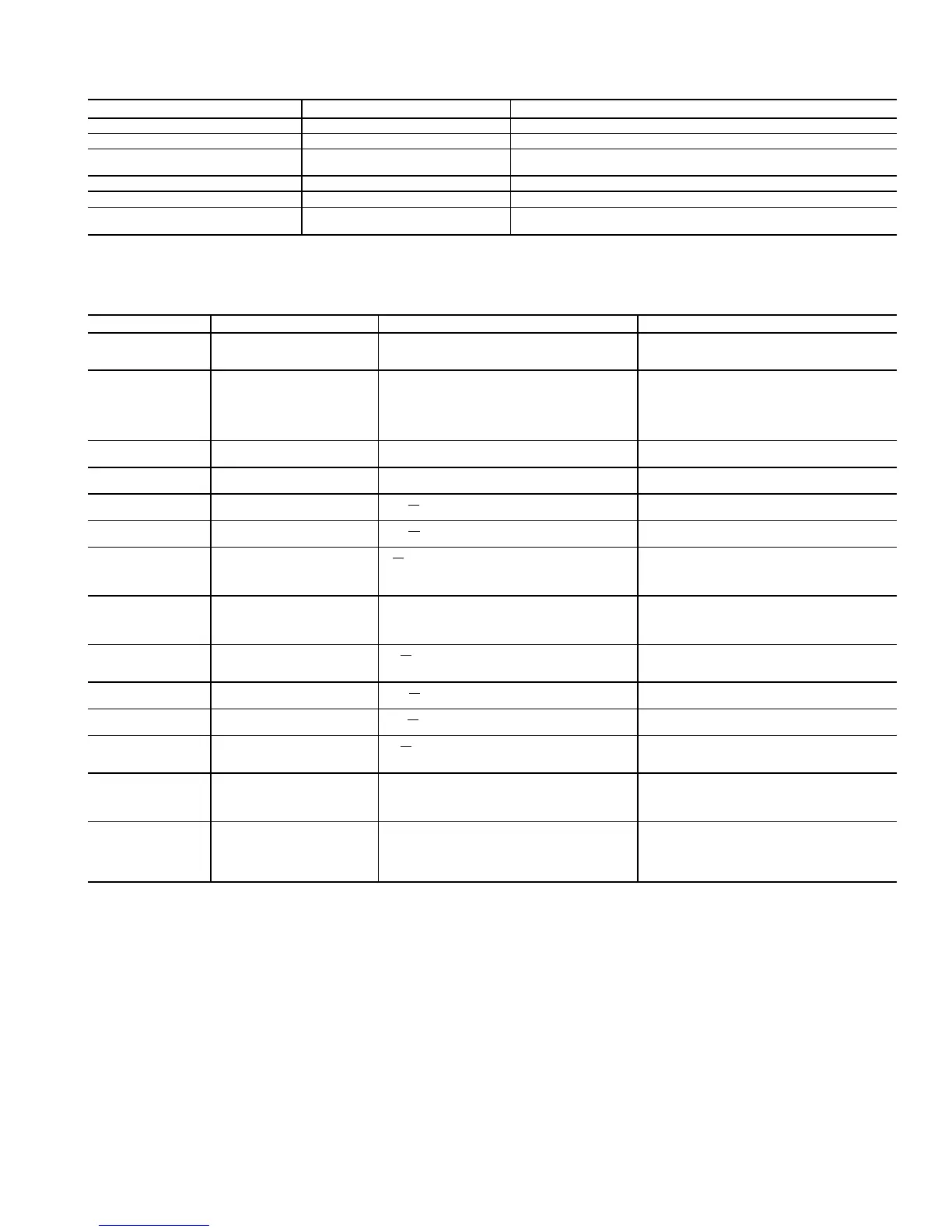

F. START-UP FAILURES: This is an alarm condition. A manual reset is required to clear.

PRIMARY MESSAGE SECONDARY MESSAGE ALARM MESSAGE/PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

FAILURE TO START LOW OIL PRESSURE OILPD [VALUE] exceeded limit of [LIMIT]*. Check

oil pump system.

Check for closed oil supply valves. Check oil filter.

Check for low oil temperature. Check transducer

accuracy.

FAILURE TO START OIL PRESS SENSOR FAULT OILPD [VALUE] exceeded limit of [LIMIT]*. Check

oil pressure sensor.

Check for excessive refrigerant in oil sump. Run oil

pump manually for 5 minutes. For hermetic com-

pressors, check both oil pressure and cooler pres-

sure. For open-drive units, check calibration of oil

pressure differential amplifier modules. Check wir-

ing. Replace transducers if necessary.

FAILURE TO START LOW CHILLED WATER FLOW EVFL Evap Flow Fault: Check water pump/flow

switch.

Check wiring to flow switch. Check through Control

Test for proper switch operation.

FAILURE TO START LOW CONDENSER

WATER FLOW

CDFL Cond. Flow Fault: Check water pump/flow

switch.

Check wiring to flow switch. Check through Control

Test for proper switch operation.

FAILURE TO START STARTER FAULT STR FLT Starter Fault: Check Starter for Fault

Source.

Astarter protective device has faulted. Check starter

for ground fault, voltage trip, temperature trip, etc.

FAILURE TO START STARTER OVERLOAD TRIP STR FLT Starter Overload Trip: Check amps

calibration/reset overload.

Reset overloads, check ICR relay before restarting

machine.

FAILURE TO START LINE VOLTAGE DROPOUT V P Single-Cycle Dropout Detected: Check volt-

age supply.

Check voltage supply. Check transformers for sup-

ply. Check with utility if voltage supply is erratic. Moni-

tor must be installed to confirm consistent, single-

cycle dropouts. Check low oil pressure switch.

FAILURE TO START HIGH CONDENSER

PRESSURE

High Condenser Pressure [LIMIT]:* Check switch

2C aux, and water temperature/flow.

Check for proper design condenser flow and tem-

perature. Check condenser approach. Check 2C aux-

iliary contacts on oil sump starter. Check high pres-

sure switch.

FAILURE TO START EXCESS ACCELERATION

TIME

CA P Excess Acceleration: Check guide vane clo-

sure at start-up.

Check that guide vanes are closed at start-up. Check

starter for proper operation. Reduce unit pressure

if possible.

FAILURE TO START STARTER TRANSITION

FAULT

RUN AUX Starter Transition Fault: Check 1CR/

1M/Interlock mechanism.

Check starter for proper operation.

Run contact failed to close.

FAILURE TO START 1CR AUX CONTACT FAULT 1CR AUX Starter Contact Fault: Check 1CR/1M

aux. contacts.

Check starter for proper operation.

Start contact failed to close.

FAILURE TO START MOTOR AMPS NOT SENSED CA P Motor Amps Not Sensed: Check motor load

signal.

Check for proper motor amps signal to SMM. Check

wiring from SMM to current transformer. Check main

motor circuit breaker for trip.

FAILURE TO START CHECK REFRIGERANT TYPE Current Refrigerant Properties Abnormal — Check

Selection of refrigerant type

Pressures at transducers indicate another refriger-

ant type in Control Test. Make sure to access the

ATTACH TO NETWORK DEVICE table after speci-

fying HFC-134a refrigerant type.

FAILURE TO START LOW OIL PRESSURE LowOilPressure [LIMIT]:* Check oil pressure switch/

pump and 2C aux.

The oil pressure differential switch is open when the

compressor tried to START. Check the switch for

proper operation. Also, check the oil pump interlock

(2C aux) in the power panel and the high con-

denser pressure switch.

*[LIMIT] is shown on the LID as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or alarm condition. [VALUE]

is the actual pressure, temperature, voltage, etc., at which the control tripped.

87

Loading...

Loading...