17

TROUBLESHOOTING

Systems Communication Failure

If communication is lost with the User Interface (UI), the control

will flash the appropriate fault code (see Table 7). Check the wiring

to the User Interface and the indoor and outdoor units and power.

Model Plug

Each control board contains a model plug. The correct model plug

must be installed for the system to operate properly (see Table 4).

The model plug is used to identify the type and size of unit to the

control.

On new units, the model and serial numbers are inputted into the

AOC

board s memory at the factory. If a model plug is lost or

missing at initial installation, the unit will operate according to the

information input at the factory and the appropriate error code will

flash temporarily. An RCD replacement AOC board contains no

model and serial information. If the factory control board fails, the

model plug must be transferred from the original board to the

replacement board for the unit to operate.

When installing heat pump with older fan coils, a model plug

change may be required. See table 2 for fan coils requiring model

plug change.

NOTE: The model plug takes priority over factory model

information input at the factory. If the model plug is removed after

initial power up, the unit will operate according to the last valid

model plug installed, and flash the appropriate fault code

temporarily.

Table 4 – Factory Supplied Model Plug Information

25VNA8

MODEL PLUG

NUMBER

PIN RESISTANCE

( K --- o h m s )

P i n s 1 --- 4 P i n s 2 --- 3

13 HK70EZ029 11K 220K

24A* 25 HK70EZ001 5.1K 11K

24B* HK70EZ009 5.1K 91K

36 HK70EZ002 5.1K 18K

37 HK70EZ026 11K 120K

48 HK70EZ003 5.1K 24K

60 HK70EZ004 5.1K 33K

* 24A unit height is 38---7/16” and 24B unit height is 31---5/ 8”

Service Tool

A150062

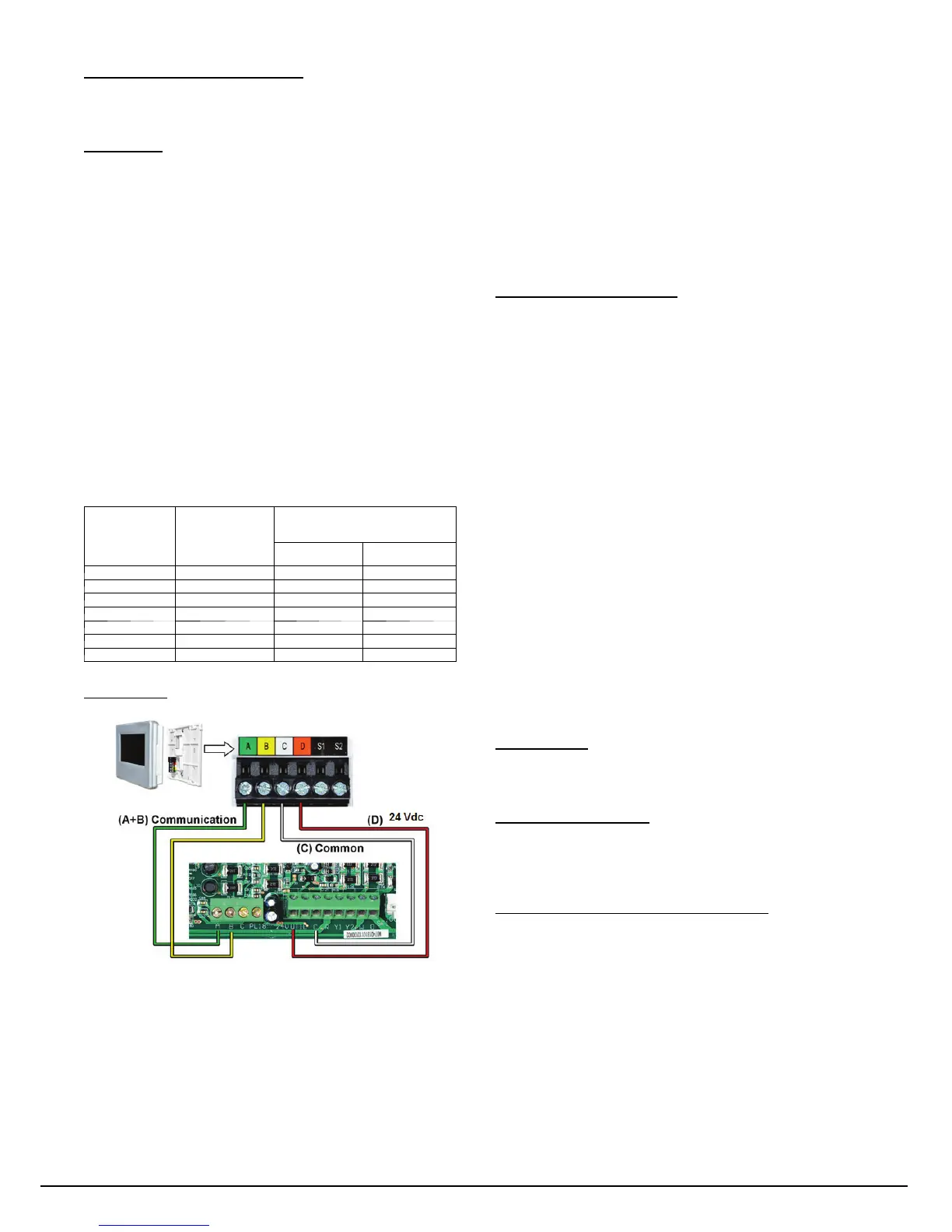

Fig. 35 -- Service Tool Connection

When working on the outdoor unit of a split system, the technician

would usually need to repeatedly walk between the indoor wall

control and the unit outside. To save time, the communicating

controls offer a service tool feature.

By wiring the service tool into the AOC board and powering it

with an external adapter, the technician can have a wall control

capable of running the system right at the outdoor unit.

To use a service tool, connect the A and B communication bus

wires from this second communicating control to the terminals

marked A and B on the terminal strip located in the bottom left

corner of the AOC board (see Fig. 35). But instead of connecting

the wires on the service tool to the terminals marked C and D,

connect the C and D wires from the service tool to the 24V and C

on ST1 as shown in Fig. 35.

When the service tool is connected and powered up, the

communicating controls inside the home will ”go to sleep” and let

the service tool take control of the system. In this manner, the

service technician can run the diagnostic checkouts right at the

outdoor unit using the service tool.

After the checkouts are completed and it is no longer necessary to

use the service tool, remove it from the communicating controls

and the indoor communicating controls will regain control in about

two minutes.

Pressure Switch Protection

The outdoor unit is equipped with high pressure switch. If the

control senses the opening of a high pressure switch (open 600+/-- 5

psig, close 470+/--10 psig @77_F), it will respond as follows:

1. Display the appropriate fault code (see Table 7).

2. After a 15 minute delay, if there is a call for cooling or heat-

ing and HPS is reset, the PEV opens for 150 seconds to

equalize system pressures. The compressor and fan will then

ramp to the next lower stage of operation until demand is

satisfied. In the next call for heating/cooling system will re-

sume normal operation.

3. If the opened switch closes at any time after the 15 minute

delay, then the PEV opens for 150 seconds to equalize sys-

tem pressures. The compressor and fan will then ramp to the

next lower stage of operation until demand is satisfied. In

the next call for heating/cooling system will resume normal

operation.

4. If HPS trips 3 consecutive cycles, the unit operation is

locked out for 4 hours.

5. In the event of a high--pressure switch trip or high--pressure

lockout, check the refrigerant charge, outdoor fan operation,

and outdoor coil (in cooling) for airflow restrictions, or in-

door airflow in heating.

6. In the event of a low--pressure trip or low--pressure lockout,

check the refrigerant charge and indoor airflow (cooling)

and outdoor fan operation and outdoor coil in heating.

Control Fault

If the outdoor unit control board has failed, the control will flash

the appropriate fault code (see Table 7). The control board should

be replaced.

Brown--Out Protection

If the line voltage is less than 187V for at least 4 seconds, the

Compressor and OD fan goes to 0 rpm. Compressor and fan

operation are not allowed until voltage is a minimum of 190V. The

control will flash the appropriate fault code (see Table 7).

230V Line (Power Disconnect) Detection

The control board senses the presence of absence of 230V through

inverter feedback. Voltage should present at all times when system

is in service regardless if system is running or standby. If there is

no 230V at the inverter when the indoor unit is powered with a

cooling or heating demand, the appropriate fault code is displayed

on UI (communicating only – see Table 7). If system is configured

with conventional heat pump thermostat (non-- communicating), no

fault code will be displayed on AOC board, nor will any status

LEDs be lit. Use multimeter to check for the presence of 230V in

this situation.

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations .

Catalog No: 25

N

8 --- 5 S I

Replaces: 25VNA8---4SI

Loading...

Loading...