21

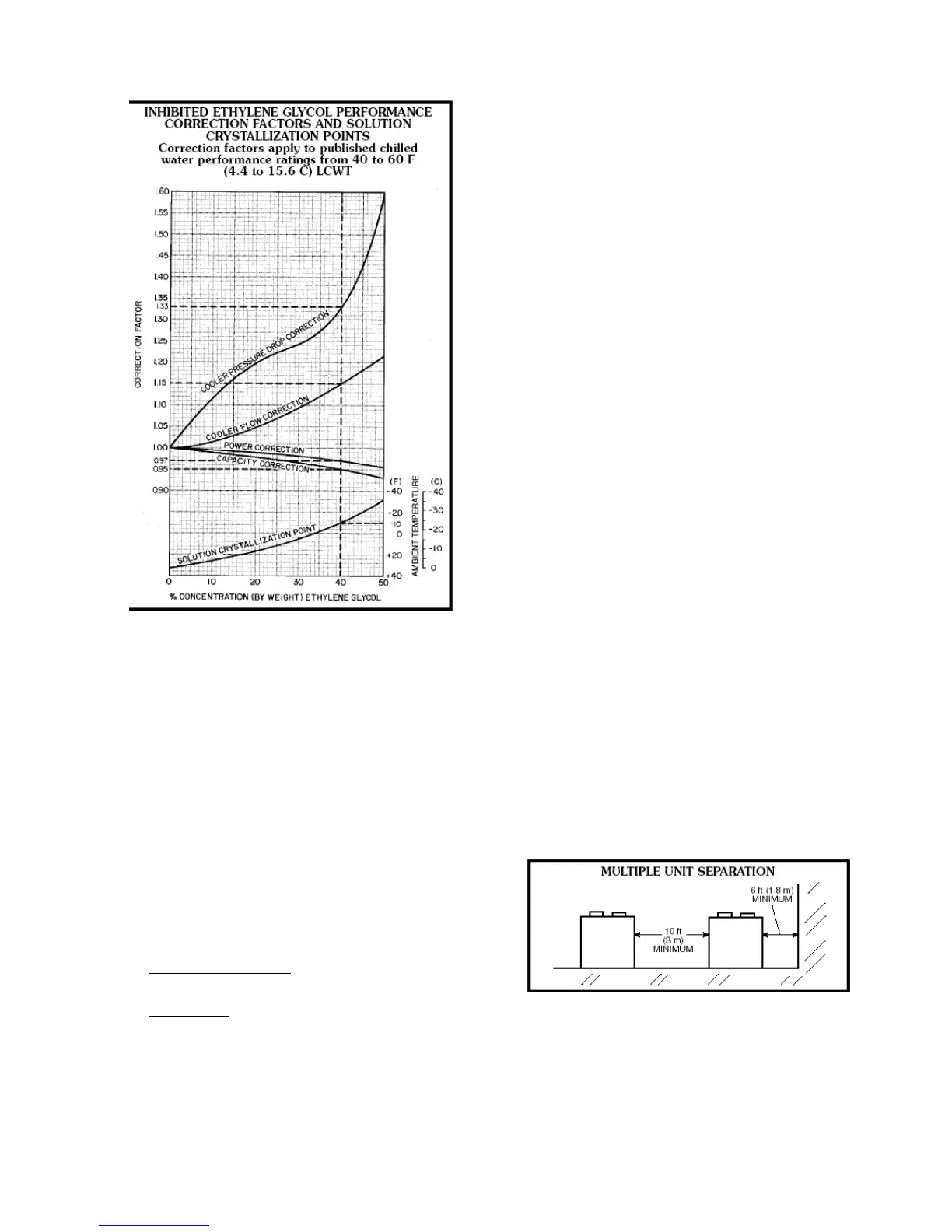

Example: SI — Determine concentration of inhibited

ethylene glycol to protect the system to –23 C ambient

temperature at zero flow.

Enter the solution crystallization point curve above,

at –23 C, read 40% concentration inhibited ethylene

glycol is required to prevent crystals from forming in

solution.

Consider 30GTN110 unit selected from the Selection

Procedure example (refer to correction curves at 40%

solution).

Correct unit capacity — On glycol performance

capacity correction curve above, read 0.95.

Corrected capacity = 0.95 x determined capacity

= 0.95 x 379.7

= 360.7 kW

Correct chilled water flow — On cooler flow

correction

curve above, read 1.15.

Chilled water flow (at corrected capacity)

= 0.239 x corr. cap. in kW = L/s

temperature rise C

= 0.239 x 360.7 = 11.1 L/s

7.8°

Chilled water flow (40% solution) = 1.15 x 11.1

= 12.8 L/s

Correct cooler pressure drop — On cooler pressure drop

correction curve on this page, read 1.33.

On cooler pressure drop curve on page 49, for 12.8 L/s,

read pressure drop of 24 kPa. The pressure drop for 40%

solution = 1.33 x 24 = 31.92 kPa.

Correct compressor power input (kW) — On the power

correction curve on this page, read 0.97 correction factor

at 40% ethylene glycol concentration.

Power input from Selection Procedure example

= 123.2 kW.

Corrected power input = 0.97 x 123.2 = 119.5 kW.

Oversizing chillers

Oversizing chillers by more than 15% at design conditions

must be avoided as the system operating efficiency is

adversely affected (resulting in greater or excessive

electrical demand). When future expansion of equipment is

anticipated, install a single chiller to meet present load

requirements and add a second chiller to meet the additional

load demand.

It is also recommended that 2 smaller chillers be installed

where operation at minimum load is critical. The operation

of a smaller chiller loaded to a greater percentage ove

its minimum recommended value.

Hot gas bypass should not be used as a means to allow

oversizing chillers. Hot gas bypass should be given

consideration where substantial operating time is anticipated

below the minimum unloading step.

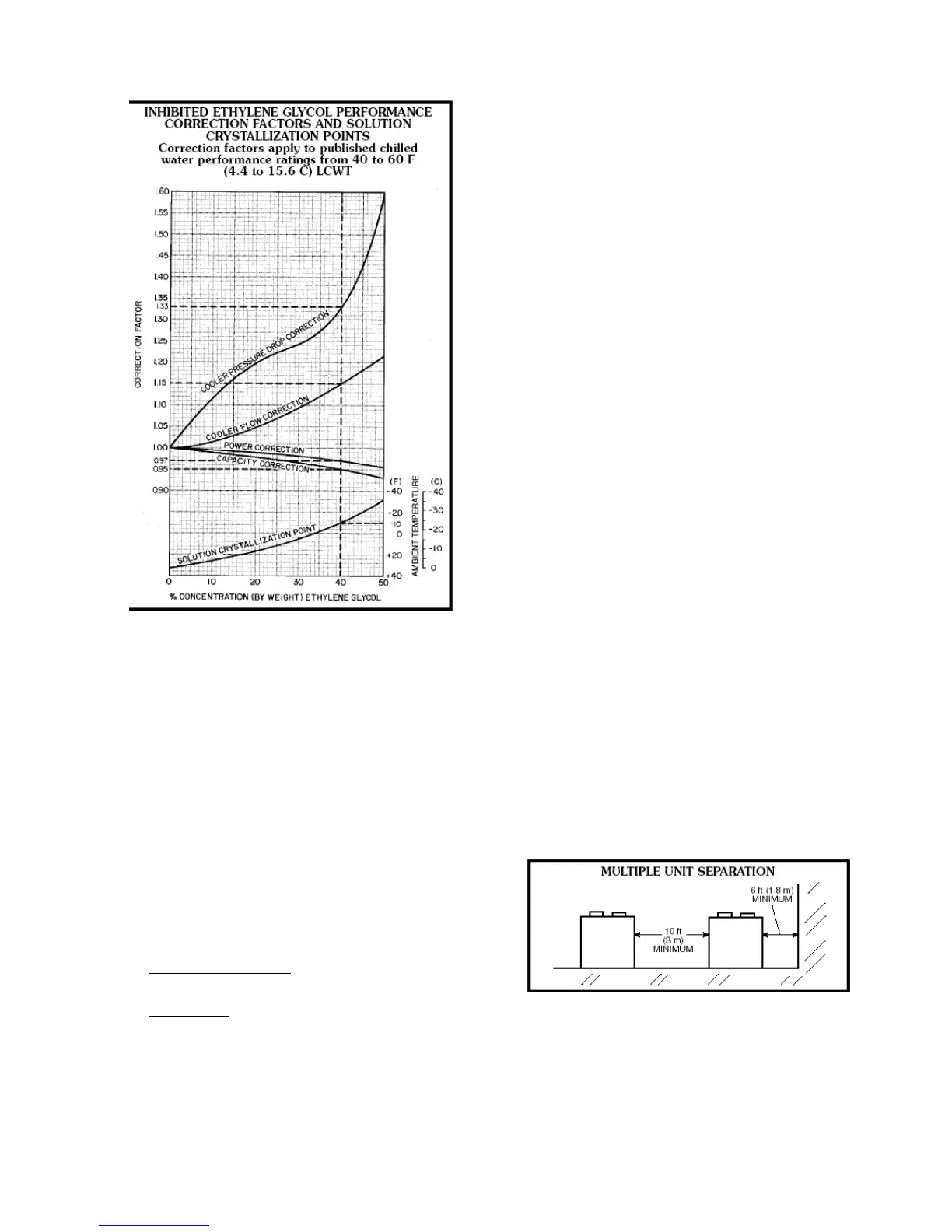

Multiple chillers

Where chiller capacities greater than 200 tons (703 kW) are

required, or where stand-by capability is desired, chillers

may be installed in parallel. Units should be of equal size to

ensure balanced fluid flows. Where a large temperature drop

(> 25° F [13.9° C]) is desired, chillers may be installed in

series. Fluid temperature sensors need not be moved for

multiple chiller operation. A 10 ft (3 m) separation is

required between units for airflow, and a 6 ft (1.8 m)

distance is required from units to obstructions. See Multiple

Unit Separation figure below. See Base Unit Dimensions

section on pages 27-39 for service clearances.

Unit software is capable of controlling two units as a

single plant. Refer to Controls, Start-Up, Operation, Service,

and Troubleshooting guide for further details.

Loading...

Loading...