18

Application data

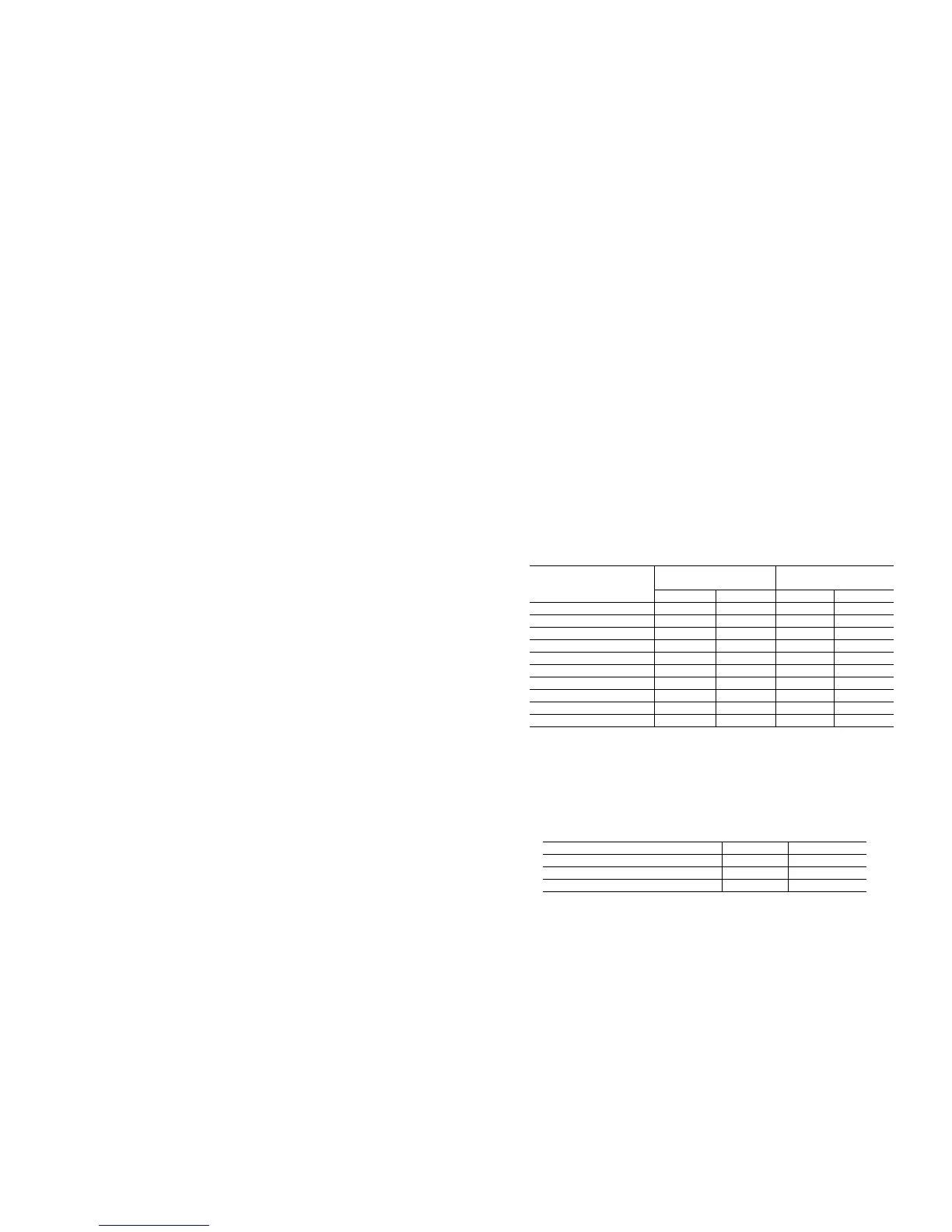

MINIMUM COOLER FLUID FLOW RATES

AND MINIMUM LOOP VOLUME

Leveling unit

Unit must be level within 1/8-in. per ft when installed to

ensure proper oil return to the compressors.

While most outdoor locations are suitable for 30GTN,GTR,

GBN,GBR units, the roof is a common site that presents a

problem if roof has been pitched to aid in water removal. To

assure proper oil return, be sure that unit is level, particularly

in its major lengthwise dimension, as compressor oil return

piping runs in that direction.

t should be determined prior to installation if any specia

treatment is required to assure a level installation.

Cooler fluid temperature

1. Maximum leaving chilled fluid temperature (LCWT) for

unit is 70 F (21 C). Unit can start and pull down with up

to 95 F (35 C) entering-fluid temperature due to MOP

(maximum operating pressure) feature of the TXV. For

sustained operation, it is recommended that entering-fluid

temperature not exceed 85 F (29.4 C).

2. Minimum LCWT for standard unit is 40 F (3.3 C). It is

permissible to use a standard microprocessor-controlled

ComfortLink™ chiller with leaving-fluid temperatures in

the range of 34 to 39.9 F (1° to 3.28 C) only if a

protective brine solution (20% antifreeze solution, or

greater) is used. (See Controls and Troubleshooting

literature for further information.)

Medium temperature brine application

Application of chiller for brine duty within the 39.9 to 15 F

(3.3 to –9.4 C) range is possible by ordering the proper

factory-installed brine option. For ratings below 38° F (3.3

C) LCWT, contact your local Carrier representative.

Leaving-fluid temperature reset

Reset reduces compressor power usage at part load when

design LCWT is not necessary. Humidity control should be

considered since higher coil temperatures resulting from

reset will reduce latent heat capacity. Three reset options are

offered, based on the following:

Return-fluid temperature — Increases LCWT temperature

set point as return (or entering) fluid temperature decreases

(indicating load decrease). Option may be used in any

application where return fluid provides accurate load

indication. Limitation of return fluid reset is that LCWT may

only be reset to value of design return fluid temperature.

Outdoor-air temperature — Increases LCWT as outdoo

ambient temperature decreases (indicating load decrease).

This reset should be applied only where outdoor ambient

temperature is an accurate indication of load. An accessory

thermistor is required.

Space temperature — Increases LCWT as space

temperature decreases (indicating load decrease). This reset

should be applied only where space temperature is an

accurate indication of load. An accessory thermistor is

required.

For details on applying a reset option, refer to uni

Controls and Troubleshooting literature. Obtain ordering

part numbers for reset option from current price pages or

contact your local Carrier representative.

Cooler flow range

Ratings and performance data in this publication are for

a cooling temperature rise of 10° F (6° C), and are

suitable for a range from 5 to 20 F (2.8 to 11.1 C)

temperature rise without adjustment. The ComfortLin

chillers may be operated using a different temperature

range, provided flow limits are not exceeded. Fo

minimum flow rates, see Minimum Cooler Fluid Flow

Rates and Minimum Loop Volume table. High flow rate

is limited by pressure drop that can be tolerated. I

another temperature range is used, apply LCWT

correction as given in Selection Procedure example on

page 53.

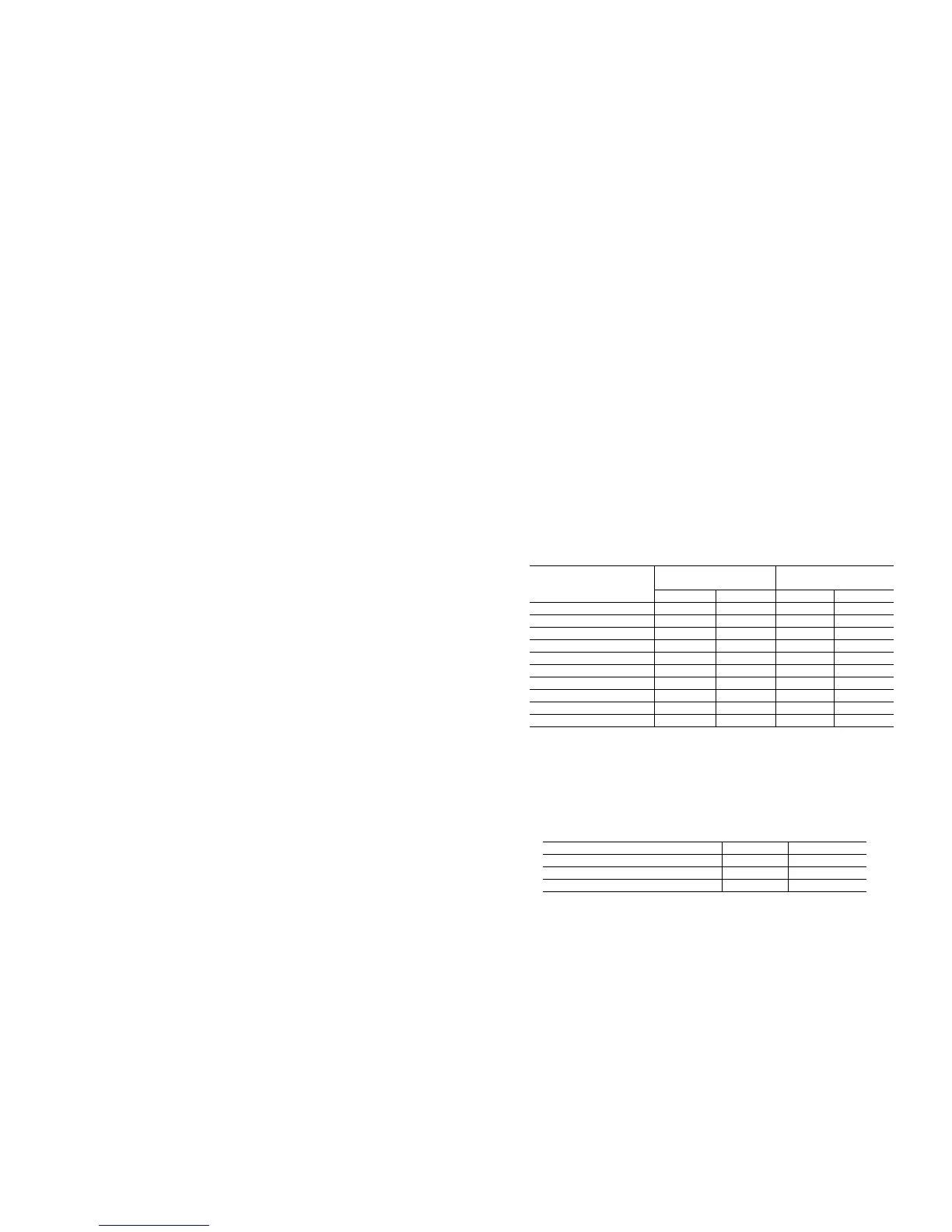

APPLICATION V N

Normal Air Conditioning 33.25

Process Type Cooling 6 to 10 6.5 to 10.8

Low Ambient Unit Operation 6 to 10 6.5 to 10.8

NOTES:

1. Minimum flow based on 1.0 fps (0.30 m/s) velocity in cooler without special

cooler baffling.

2. Minimum Loop Volumes:

Gallons = V x ARI Cap. in tons

Liters = N x ARI Cap. in kW

MINIMUM COOLER

FLOW RATE

MINIMUM LOOP

VOLUME

UNIT SIZE

30GTN,GTR,GBN,GBR

Gpm L/s Gal L

050 37.7 2.38 153 580

060 47.5 3.00 181 684

070 47.5 3.00 210 796

080 66.7 4.20 243 920

090 59.5 3.75 272 1029

100 84.1 5.30 301 1138

110 81.1 5.30 333 1260

150, 300A/B 192.0 6.90 502 1900

175, 350A/B 192.0 6.90 568 2150

200, 400A/B 192.0 6.90 635 2403

Loading...

Loading...