8

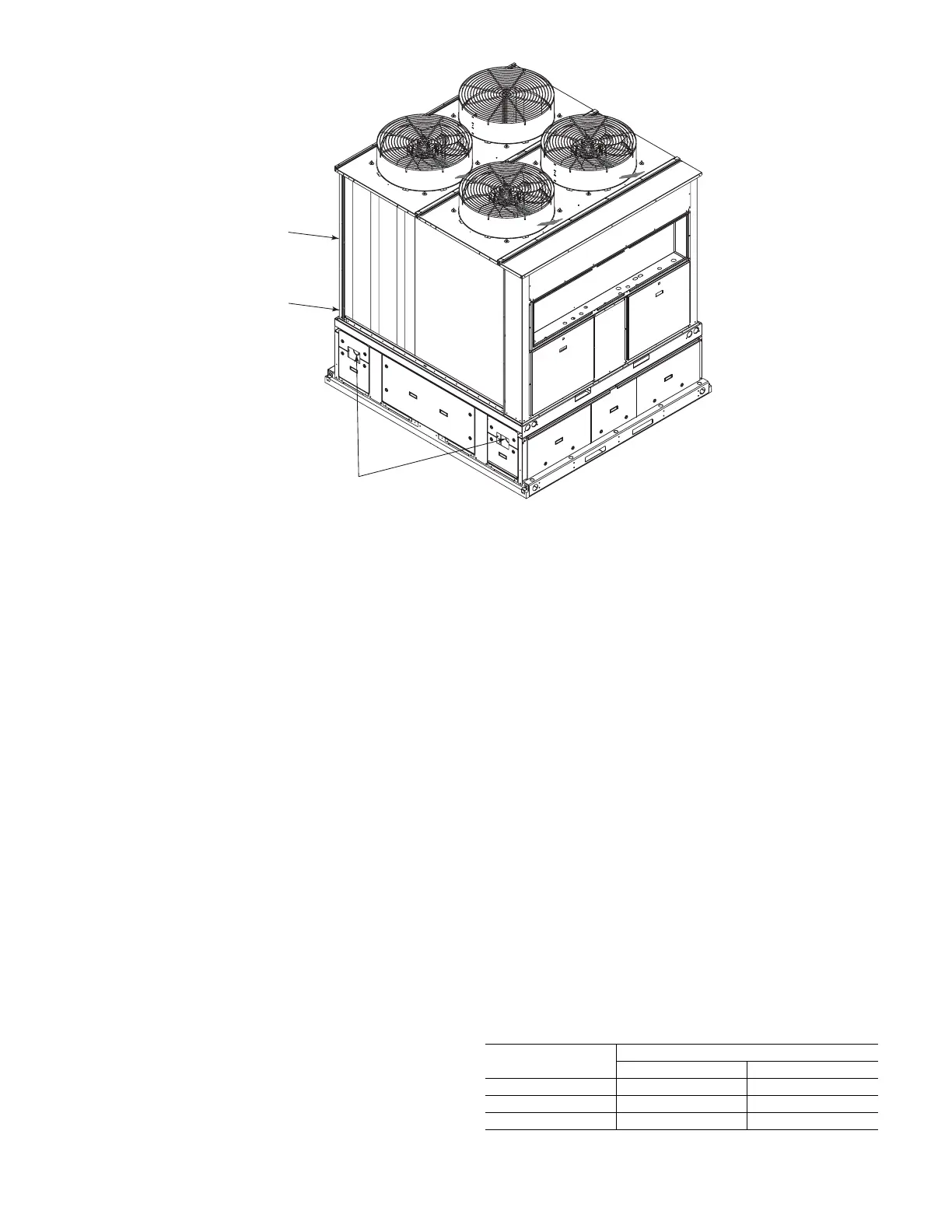

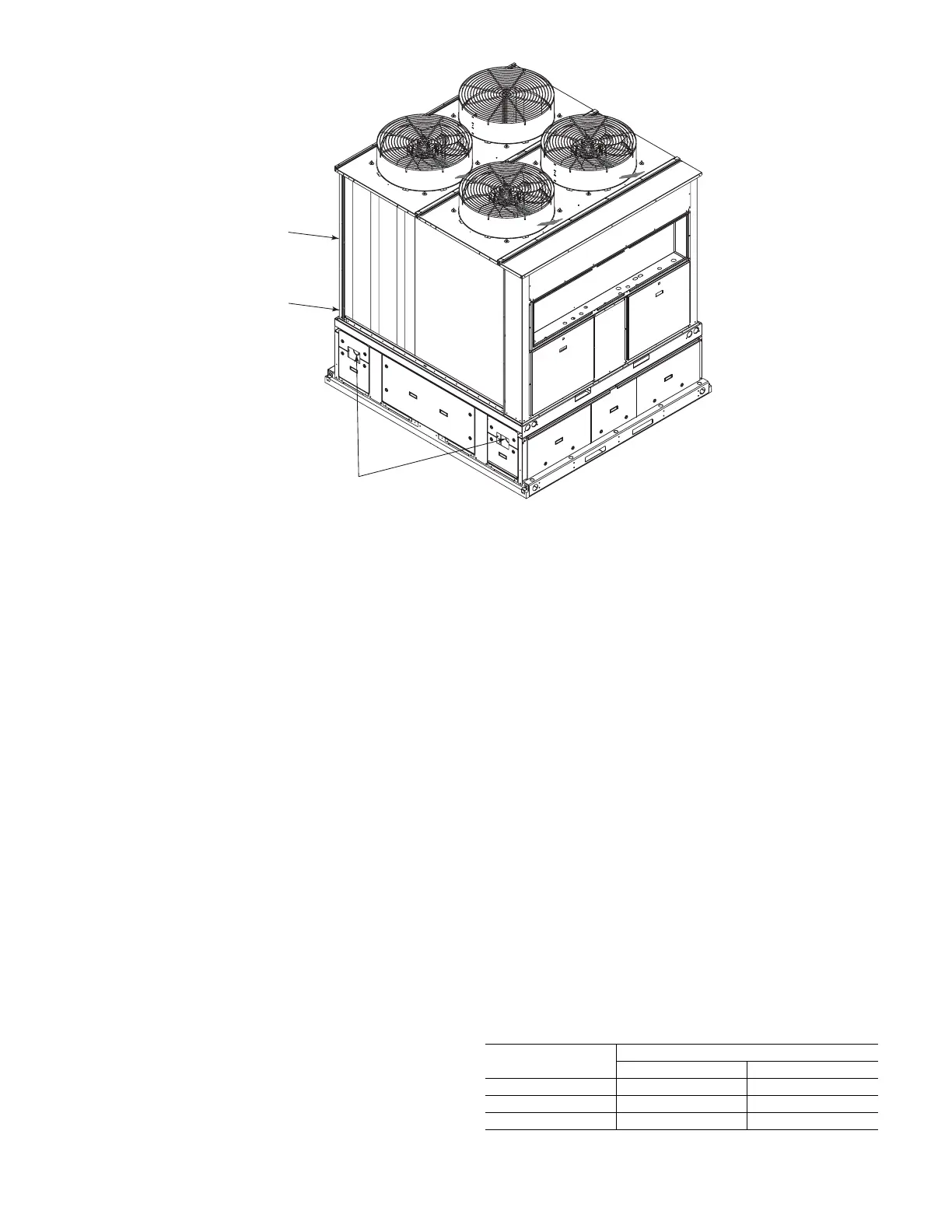

Fig. 8 — Typical Piping Layout — 30RA-900---052

Step 3 — Make Electrical Connections

POWER SUPPLY

The storage tank does not require a power connection to the tank

heater if the chilled fluid has been properly treated with a suitable

anti-freeze solution or the chilled fluid is drained during the winter

season. If this is the case, installation is complete and the tank

electric heater is not used.

ELECTRIC HEAT

The water storage tanks are provided with electric heaters to pre-

vent freeze-up during low ambient temperature conditions. The

heaters will provide freeze protection to –20°F (–28.9°C). Care

must be taken to prevent freeze-up in the event of a power loss.

CONDUIT CONNECTION

The tank power is provided from the main unit control box. Con-

duit is supplied in the accessory kit which needs to be installed be-

tween the main control box and the tank heater control box. Per-

form the following steps to install the conduit:

1. Make a 0.75 in. (19 mm) diameter hole using a drill or punch

per Fig. 9-11.

2. Knock out the conduit entry hole in the tank control box. See

Fig. 12.

3. Remove the conduit connector from the end of the conduit

opposite the end with ring terminals.

4. From inside the compressor section of the unit, feed the con-

duit through 0.75 in. (19 mm) hole made in Step 1.

5. Route the conduit between storage tanks to the storage con-

trol box and install connector removed in Step 3.

6. Make conduit connection to power entry hole in tank control

box shown in Fig. 12.

7. Make power connections in tank control box to TB1A. Con-

nect black wire to terminal 11. Connect yellow wire to termi-

nal 12. Connect green wire to ground connection.

8. Connect red and brown control wires from conduit to red and

brown wires in tank control box using wire nuts supplied in

hardware kit.

9. Check tank heater wiring for proper termination. See Fig. 13.

Accessories are shipped from the factory for high voltage

wiring and if applied at 208/230 volts, will not have freeze

protection down to –20°F (–28.9°C). A warning label is

affixed to the tank to alert installers if the power supply is

208/230 volts. See Fig. 14. For 208/230 v units, the heater

elements must be wired in parallel instead of series. Recon-

nect the black, red, and white wires in the tank heater wiring.

See Fig. 13.

NOTE: Tank heater wiring in both control boxes (control box

1 and 2) must be changed for the 30RA-900---052 accessory.

10. Relocate HPS and EXV wires for sizes 015-030 and HPS-B

wires for sizes 035-060 to compressor wire entry. See Fig. 15

and 16.

11. Route the end of the conduit assembly through the hole used

for the HPS entry into the control box. Use the adapter

washer provided with the hardware kit.

12. Make power connections to appropriate compressor circuit

breaker as required. See Table 3 and Fig. 17.

13. Make control wire connection with RED and BROWN wires

from conduit to wires labeled TNKR-HTR (RED) and

TNKR-COM (BRN) located next to the low voltage terminal

strip in main control box.

Table 3 — Compressor Circuit Breakers

Tank

Inlet/outlet

Water

Inlet

(Hidden)

Water

Outlet

(Hidden)

30RAP

UNIT SIZE

CONNECTION

BLK WIRE YEL WIRE

010,015 CCB-1-21 CCB-1-22

018-030 CCB-1-21 CCB-1-22

035-060 CCB-3-21 CCB-3-22

Loading...

Loading...