7

Step 2 — Connect Cooler Fluid and Drain Piping

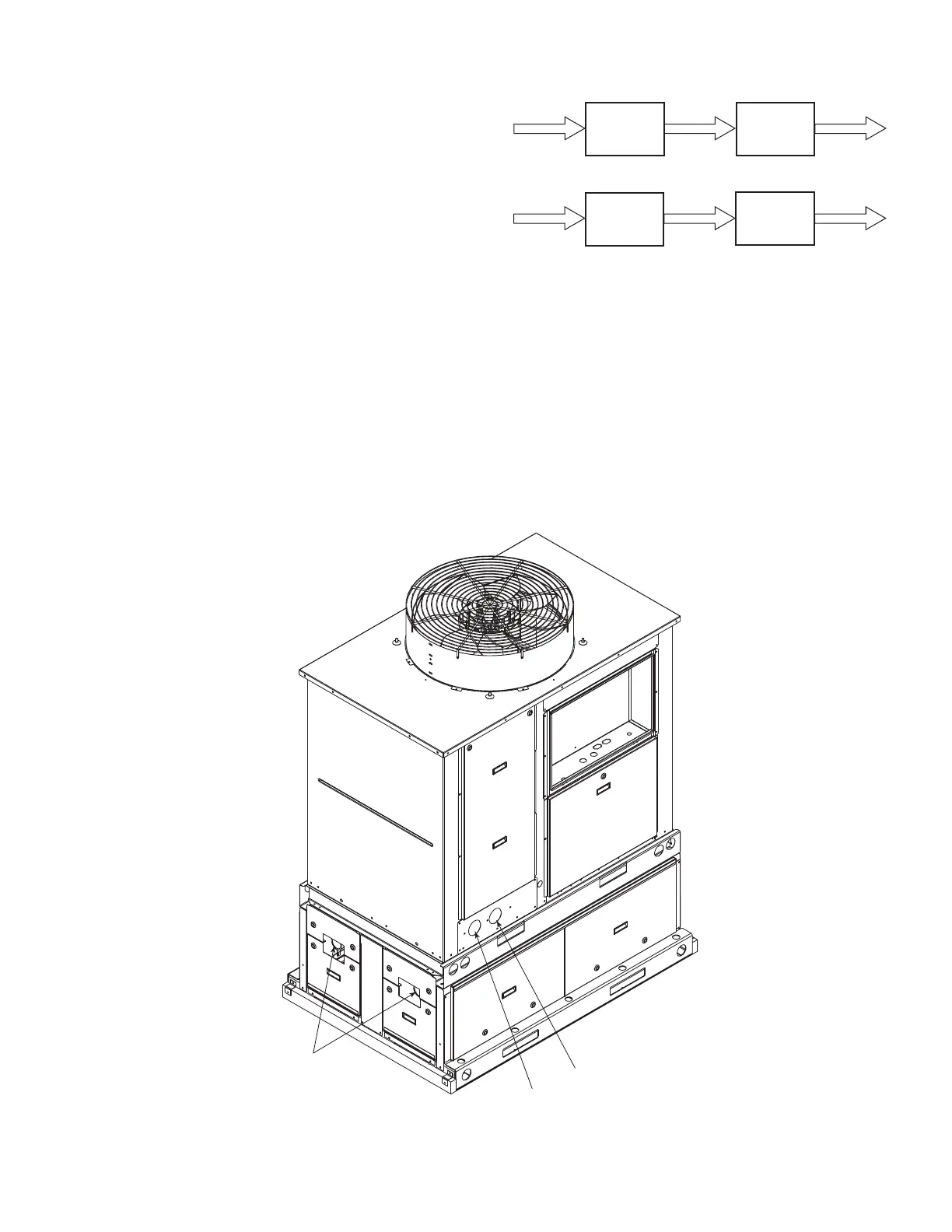

The piping between the chiller and the accessory tank can be done

to allow the tank to be on the return side of the chiller (tank piped

to chiller inlet) or the supply side of the chiller (tank piped to the

chiller outlet). See Fig.

6. However, it is recommended that the

tank be piped to the return side of the chiller to buffer any changes

in load to allow more stable chiller operation. For digital compres

-

sor applications, it is recommended that the tank be piped to the

supply side of the chiller to provide a more stable supply tempera

-

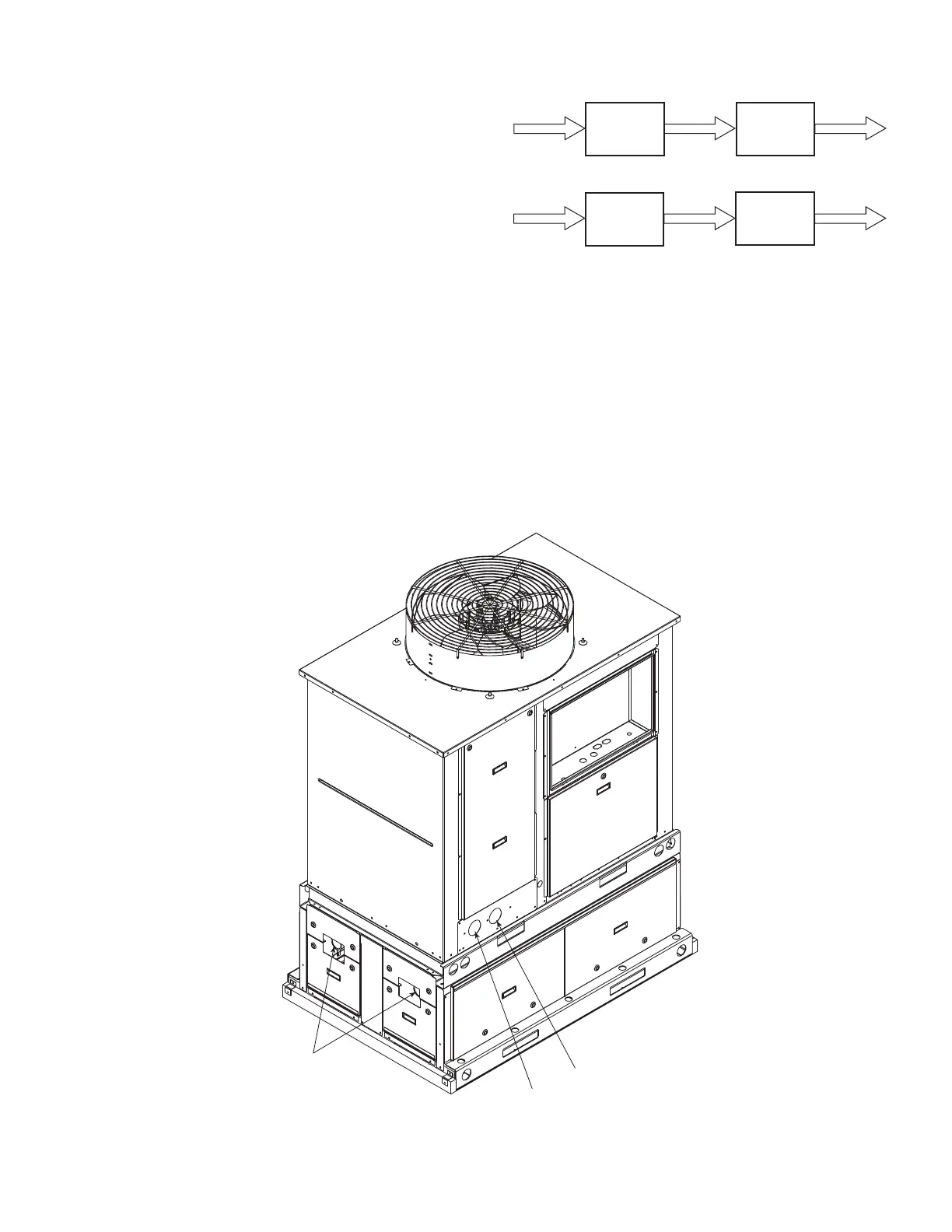

ture. See Fig. 7 and 8 for an examples of piping layouts.

All sizes have 2-1/2 in. Victaulic connections. Provide a means of

venting air from the high point of the field-installed piping as re

-

quired. All sizes also have 2 in. drains at the bottom of each end of

the storage tanks. This size has been provided to allow cleaning of

foreign material that may collect at the bottom of the tanks.

After field piping is complete, freeze protection is recommended

using inhibited ethylene glycol or other suitable inhibited anti-

freeze solution and electric heat tapes in area where piping is ex-

posed to low ambient temperatures (34°F [1°C] or below). Heat

tapes should be rated for area ambient temperatures and be cov-

ered with a suitable thickness of closed-cell insulation. Route

power for heating tapes from a separately fused disconnect. Identi

-

fy disconnect as heat tape power source with a warning that power

must not be turned off except when unit is being serviced.

PREPARATION FOR YEAR-ROUND OPERATION

If unit is in operation year-round, add sufficient inhibited ethylene

glycol or other suitable inhibited antifreeze solution to chilled wa

-

ter to prevent freezing under low-ambient operating conditions.

Consult local water treatment specialist on characteristics of water

and recommended inhibitor.

Fig. 6 — Typical Chiller/Tank Setup

PREPARATION FOR WINTER SHUTDOWN

Do not shut off electrical disconnect during off-season shutdown.

At end of cooling season:

1. Make sure LOCAL/OFF/REMOTE switch is in the OFF

position on the chiller.

2. Drain water from the accessory tank system.

3. Replace drain plugs and fill tanks with a rust inhibiting anti-

freeze solution to prevent freezing of residual water and rust

build-up.

4. At beginning of the each cooling season, refill cooler and add

recommended inhibitor.

Fig. 7 — Typical Piping Layout — 30RA-900---050,051

Accessory

Tank

Recommended Piping Scheme

Alternate Piping Scheme

30RAP

Chiller

Accessory

Tank

30RAP

Chiller

Water

Inlet

Tank

Inlet/Outlet

Water

Outlet

Loading...

Loading...