38MURA: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

13

8. Brazing Adapter (Optional)

When flare to braze adapter is used, follow these steps:

a. Refer to the liquid line and gas line connection O.D. sizes in

Table 7 based on the model being installed. Cut and deburr the

tubing (review “Remove the Burrs on page 11.) to prepare it

for brazing. Setup the nitrogen apparatus and connect to the

outside unit to flow nitrogen while brazing. Braze the tubing

and any fittings to obtain a proper seal.

b. Adjust the nitrogen apparatus to pressurize the system. Pressure

test the system to a maximum of 500 psig for at least 60

minutes.

c. Insulate suction line completely, including the outdoor unit

valves.

9. Pressure Test Piping

NOTE: Use refrigeration gauges that are pressure rated for R410a

refrigerant.

a. Attach low side gauge hose to the 5/16” Schrader valve

on the outdoor unit service valve.

b. Attach the charging hose to the regulator on the dry nitrogen

tank.

c. Preset the nitrogen regulator to 550 psi.

d. Slowly pressurize the line set until the low side gauge reads 500

psi. Do not exceed 550 psi.

e. Close all the valves on the nitrogen tank and gauges.

f. Allow the pressure test to stand for a minimum of 30 minutes.

g. If the pressure holds, release the nitrogen and proceed with

“Step 6 - Electrical Connections - Dip Switch Configuration on

page 13.

h. If the pressure goes down in the 30 minute delay, leak check the

tubing and flare fittings to identify the source of the leak.

Return to Step C, above.

Additional Refrigerant Requirements

Step 6 - Electrical Connections - Dip Switch

Configuration

Install All Power and Interconnecting Wiring to

Outdoor Units

1. Mount the outdoor power disconnect.

2. Run the power wiring from the main box to disconnect per NEC and

local codes.

3. Remove the field wiring cover from the unit by loosening the screws.

4. Remove the caps on the conduit panel.

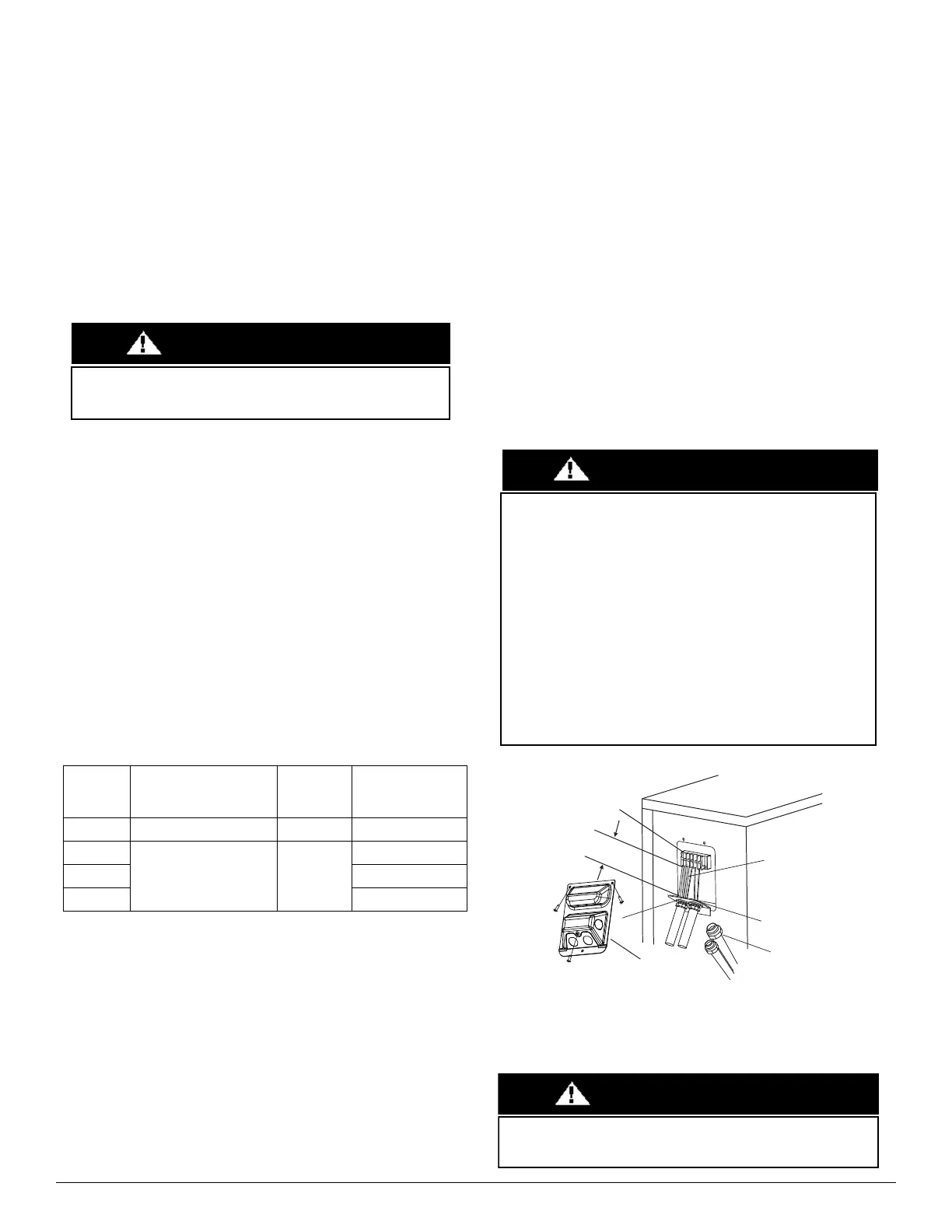

5. Connect the conduit to conduit panel (see Fig. 19).

6. Properly connect both the power supply and control lines to the

terminal block per the connection diagram for the appropriate unit

capacity and voltage.

7. Ground the unit in accordance with NEC and local electrical codes.

8. Use the lock nuts to secure the conduit.

9. Reinstall the field wiring cover.

Fig. 19 —Field Wiring

System

Size

Max. Piping Length with no

additional refrigerant

charge per System

Additional

refrigerant

charge

Total Maximum

Piping Length per

system

ft. (m) Oz/ft (g/m) ft. (m)

18K

24.6 (7.5) 0.69 (65)

98 (30)

24K - 30K 164 (50)

36K - 60K 213 (65)

Only use Dry Nitrogen to pressure test refrigerant systems. Use of

other gases can result in injury, property damage or death.

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Be sure to comply with local codes while running wire from

indoor unit to outdoor unit.

Every wire must be connected firmly. Loose wiring may cause the

terminal to overheat or result in unit malfunction. A fire hazard

may also exist. Therefore, ensure all wiring is tightly connected.

No wire should be allowed to touch the refrigerant tubing,

compressor or any moving parts.

Disconnecting means must be provided and shall be located

within sight and readily accessible from the air conditioner.

Connecting cable with the conduit shall be routed through hole in

the conduit panel.

CAUTION

Wire Cover

Over 1.57in.(40mm)

Terminal block

Conduit panel

Conduit fitting

Connecting cable

Select the appropriate conduit opening for the

wire size used.

An approved and listed fitting must be used to securely affix

conduit in accordance with NEC and local codes.

WARNING

Loading...

Loading...