9. Reinstall 2 snap-in clips to correctly position and secure coil

assembly in unit. Be sure clip with large offset is used on right

side of unit to secure horizontal pan.

10. Remove 2 oval coil access panel plugs and reinstall into holes

on left side of coil access panel and fitting panel.

11. Remove insulation knockouts on right side of coil access

panel.

12. Reinstall access and fitting panels, aligning holes with tubing

connections and condensate pan connections. Be sure to

reinstall metal clip between fitting panel and vertical conden-

sate pan.

Make sure liquid and suction tube grommets are in place to prevent

air leaks and cabinet sweating.

DOWNFLOW INSTALLATIONS

To convert units for downflow applications, refer to Installation

Instructions supplied with kit for proper installation. For 40FKA

unit size 003, use kit Part No. KFADC0201SLP. For 40FKA unit

sizes 002, 005, and 006 use kit Part No. KFADC0401ACL. Use

fireproof resilient gasket, 1/8- to 1/4-in. thick, between duct, unit,

and floor.

Step 3—Air Ducts

Connect supply-air duct over outside of 3/4-in. flange provided on

supply-air opening. Secure duct to flange with proper fasteners for

type of duct used, and seal duct-to-unit joint.

Duct connection flanges are provided on unit air discharge

connection.

When using 40FKA units with 18-, 20-, 24-, and 30-kw electric

heaters, maintain a 1-in. clearance from combustible materials to

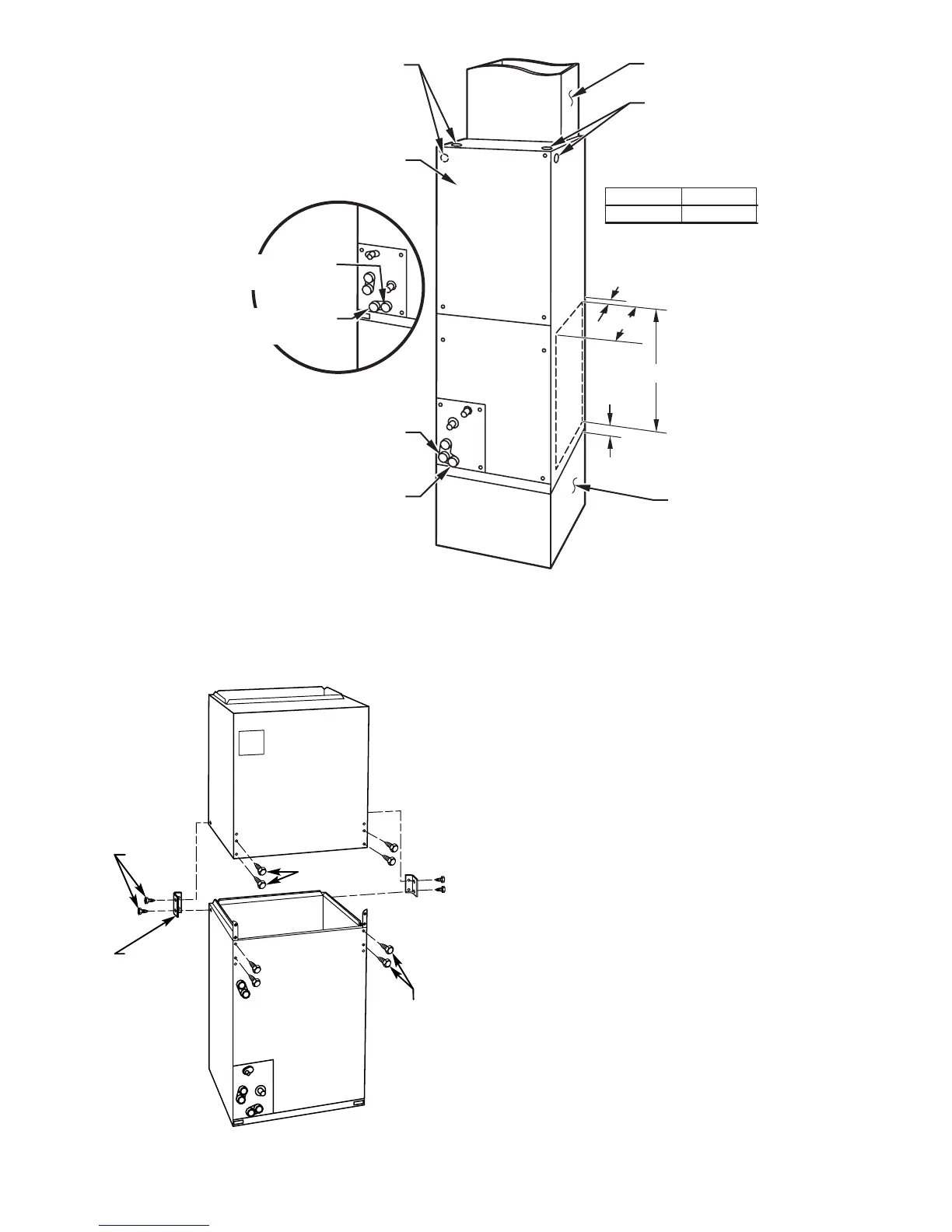

→ Fig. 2—Slope Coil in Upflow Application

A00091

A COIL

UNITS

POWER ENTRY

OPTIONS

LOW VOLT

ENTRY

OPTIONS

FIELD MODIFIED

SIDE RETURN

LOCATION FOR

SLOPE COIL

UNITS ONLY

FIELD SUPPLIED

RETURN PLENUM

UPFLOW/DOWNFLOW

SECONDARY DRAIN

UPFLOW/DOWNFLOW

PRIMARY DRAIN

UNIT

003

A

19 In.

A

1

1

⁄

2

″

2

1

⁄

2

″

19

″

FIELD SUPPLIED

SUPPLY DUCT

24-IN. FRONT SERVICE

CLEARANCE

UPFLOW/DOWNFLOW

SECONDARY DRAIN

UPFLOW/DOWNFLOW

PRIMARY DRAIN

002-005 21-IN.

006

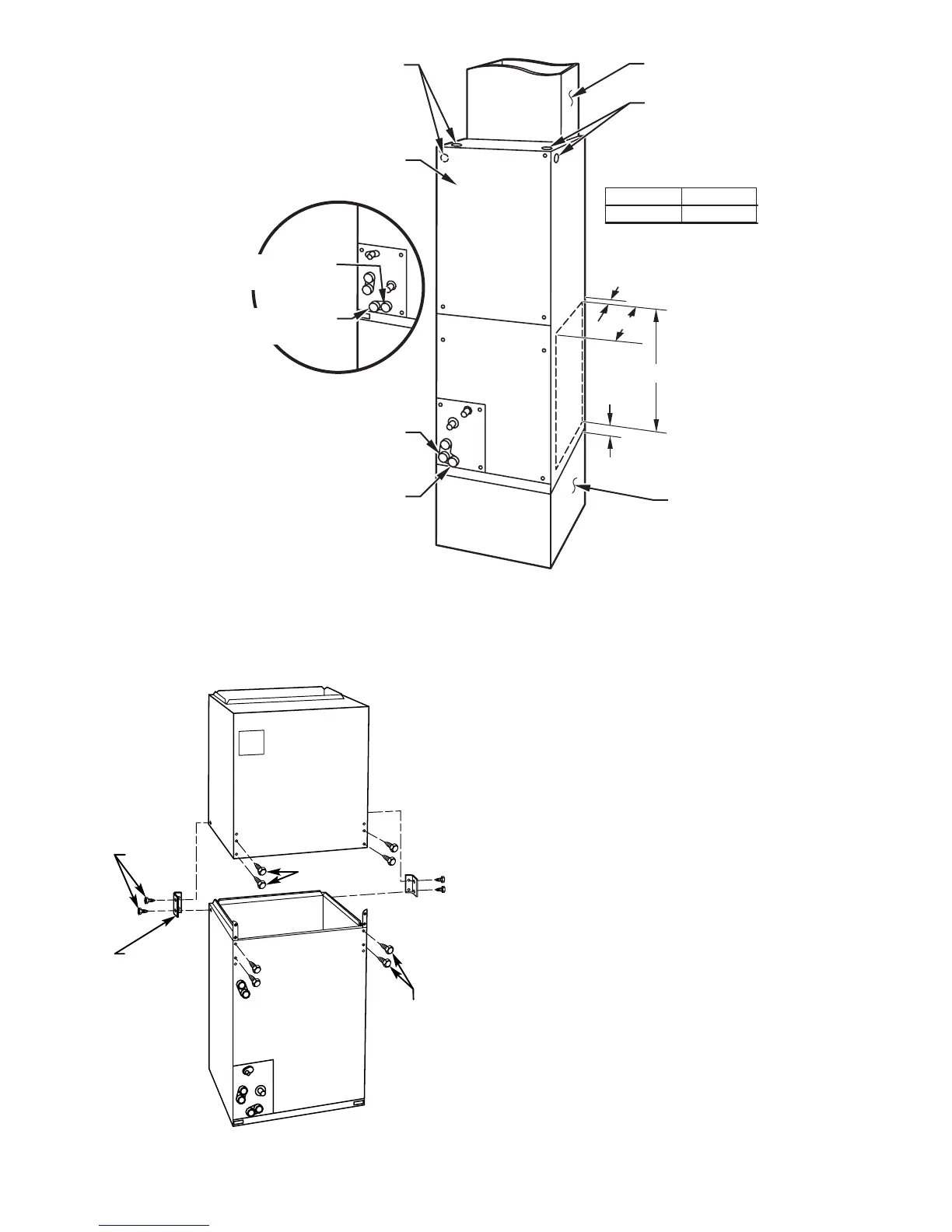

Fig. 3—Modular Unit Assembly

A95293

2 SCREWS

2 SCREWS

REAR CORNER

BRACKET

BLOWER BOX

COIL BOX

2 SCREWS

3

Loading...

Loading...