GROUND CONNECTIONS

The cabinet must have an uninterrupted or unbroken ground

according to NEC, ANSI/NFPA 70 and local codes to

minimize personal injury if an electrical fault should occur.

The ground may consist of electrical wire or metal conduit

when installed in accordance with existing electrical codes.

(See Ground/Conduit Note below.) Failure to follow this

warning could result in an electrical shock, fire, or death.

NOTE: Use UL listed conduit and conduit connector to connect

supply wire(s) to unit and obtain proper grounding. If conduit

connection uses reducing washers, a separate ground wire must be

used. Grounding may also be accomplished by using grounding

lug provided in control box. Use of dual or multiple supply circuits

will require grounding of each circuit to ground lugs provided on

unit and heaters.

Step 5—Refrigerant Tubing Connection and Evacuation

This fan coil is supplied with an R-22 TXV factory installed. If

installing as part of a Puron® system, the TXV must be replaced

using a Puron TXV. See outdoor unit literature for correct Puron

TXV Kit number.

See Dimensional Drawing in Product Data for tube connection

sizes, type, and locations. Use accessory tubing package with

insulated suction tube, or field-supplied tubing of refrigerant

grade. Insulate entire suction tube if field-supplied tubing is used.

Do not use damaged, dirty, or contaminated tubing because it may

plug refrigerant flow control device. When tubing package is used

and sweat connections are made within 60 sec, coil and tubing

system does not require evacuation. Always evacuate coil and

field-supplied tubing to 500 microns before opening outdoor unit

service valves.

A brazing shield MUST be used when tubing sets are being

brazed to the unit connections to prevent damage to the unit

surface. Braze with Sil-Fos or Phos-copper on copper to

copper joints. Wrap a wet cloth around rear of fitting to

prevent damage to TXV.

To prevent damage to thermostatic expansion valve, remove

sensor bulb from vapor tube while brazing vapor connections.

Units have sweat suction and liquid tube connections. Make

suction tube connection first.

1. Cut tubing to correct length.

2. Insert tube into sweat connection on unit until it bottoms.

3. Braze with Sil-fos or Phos-copper.

Wrap a wet cloth around rear of fitting to prevent damage to

factory-made joints.

4. Evacuate coil and tubing system if connections are not made

within 60 sec or tubing package is not used.

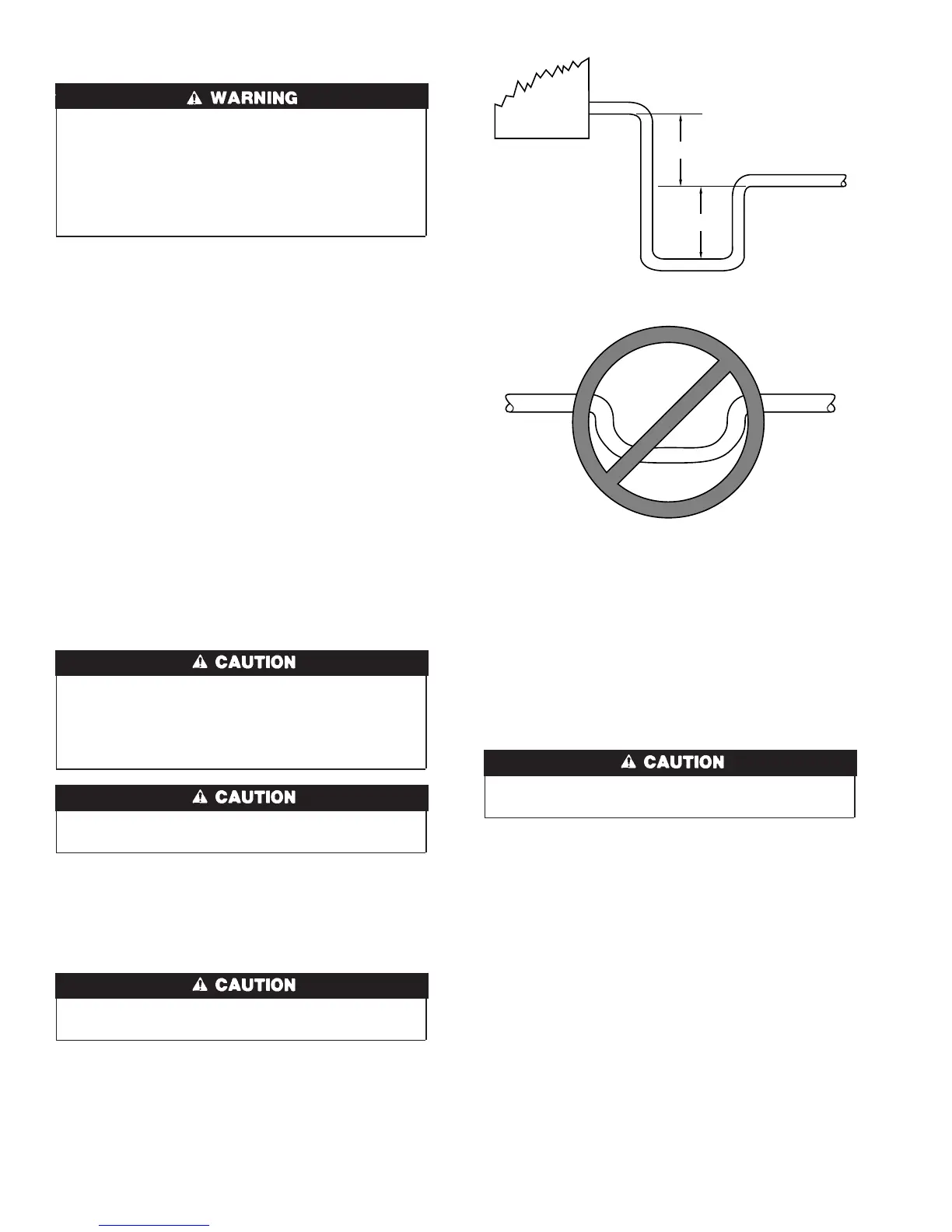

Step 6—Condensate Drain

Units are equipped with primary and secondary 3/4-in. FPT drain

connections. For proper condensate line installation see Figs. 2, 4,

5, 6, and 7. To prevent property damage and achieve optimum

drainage performance, BOTH primary and secondary drain lines

should be installed and include properly sized condensate traps.

(See Fig. 13 and 15.) Factory-approved condensate traps are

available (Kit No. KFAET0125ETK). Be sure to install plastic

push-in plugs in unused condensate drain fittings. It is recom-

mended that PVC fittings be used on the plastic condensate pan.

Do not over-tighten. Finger-tighten plus 1-1/2 turns. Use pipe

dope.

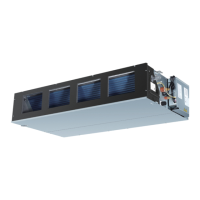

Shallow running traps are inadequate and DO NOT allow

proper condensate drainage. (See Fig. 14.)

NOTE: When connecting condensate drain lines, avoid blocking

filter access panel. Prime both primary and secondary condensate

traps after connecting to drain pan.

NOTE: If unit is located in or above a living space where damage

may result from condensate overflow, a field-supplied external

condensate pan should be installed underneath the entire unit, and

a secondary condensate line (with appropriate trap) should be run

from the unit into the pan. Any condensate in this external

condensate pan should be drained to a noticeable place. As an

alternative to using an external condensate pan, some localities

may allow the use of a separate 3/4-in. condensate line (with

appropriate trap) to a place where the condensate will be notice-

able. The owner of the structure must be informed that when

condensate flows from the secondary drain or external condensate

pan, the unit requires servicing, or water damage will occur.

Install traps in the condensate lines as close to the coil as possible.

(See Fig. 15.) Make sure that the outlet of each trap is below its

connection to the condensate pan to prevent condensate from

overflowing the drain pan. Prime all traps, test for leaks, and

insulate traps if located above a living area.

Fig. 13—Recommended Condensate Trap

A95321

2

1

⁄4″

2

1

⁄4″

UNIT

Fig. 14—Insufficient Condensate Trap

A95320

DO NOT USE SHALLOW RUNNING TRAPS!

8

→

Loading...

Loading...