discharge plenum and ductwork for a distance of 36 in. from unit.

Use accessory downflow base to maintain proper clearance on

downflow installations.

Use flexible connectors between ductwork and unit to prevent

transmission of vibration. When electric heater is installed, use

heat resistant material for flexible connector between ductwork

and unit at discharge connection. Ductwork passing through

unconditioned space must be insulated and covered with vapor

barrier.

DUCTWORK ACOUSTICAL TREATMENT

Metal duct systems that do not have a 90° elbow and 10 ft of main

duct to first branch takeoff may require internal acoustical insula-

tion lining. As an alternative, fibrous ductwork may be used if

constructed and installed in accordance with the latest edition of

SMACNA construction standard on fibrous glass ducts. Both

acoustical lining and fibrous ductwork shall comply with National

Fire Protection Association Standards 90A or B as tested by UL

Standard 181 for Class 1 air ducts.

Step 4—Electrical Connections

On units with a factory installed disconnect with pull-out removed,

service and maintenance can be safely performed on only the load

side of the control package.

Field wires on the line side of the disconnect found in the fan

coil unit remain live, even when the pull-out is removed.

Service and maintenance to incoming wiring can not be

performed until the main disconnect switch (remote to the

unit) is turned off. Failure to do so will result in electrical

shock causing personal injury or death.

LINE-VOLTAGE CONNECTIONS

If unit contains an electric heater, remove and discard power plug

from fan coil and connect male plug from heater to female plug

from unit wiring harness. (See Electric Heater Installation Instruc-

tions.)

For units without electric heat:

1. Connect 208/230v power leads from field disconnect to

yellow and black stripped leads.

2. Connect ground wire to unit ground lug.

NOTE: Units installed without electric heat should have a field-

supplied sheet metal block-off plate covering the heater opening.

This will reduce air leakage and formation of exterior condensa-

tion.

Check all factory wiring per unit wiring diagram and inspect

factory wiring connections to be sure none were loosened in transit

or installation.

Before installing or servicing system, always turn off all

power to system. There may be more than 1 disconnect

switch. Turn off accessory heater power if applicable. Elec-

trical shock can cause personal injury or death.

If a disconnect switch is to be mounted on the unit, select a

location where drill or fastener will not contact electrical or

refrigerant components. Electrical shock can cause personal

injury or death.

NOTE: Before proceeding with electrical connections, make

certain that supply voltage, frequency, and phase are as specified

on unit rating plate. Be sure that electrical service provided by the

utility is sufficient to handle the additional load imposed by this

equipment.

See unit wiring label for proper field high- and low-voltage wiring.

Make all electrical connections in accordance with NEC and any

local codes or ordinances that may apply. Use copper wire only.

The unit must have a separate branch electric circuit with a

field-supplied disconnect switch located within sight from, and

readily accessible from the unit.

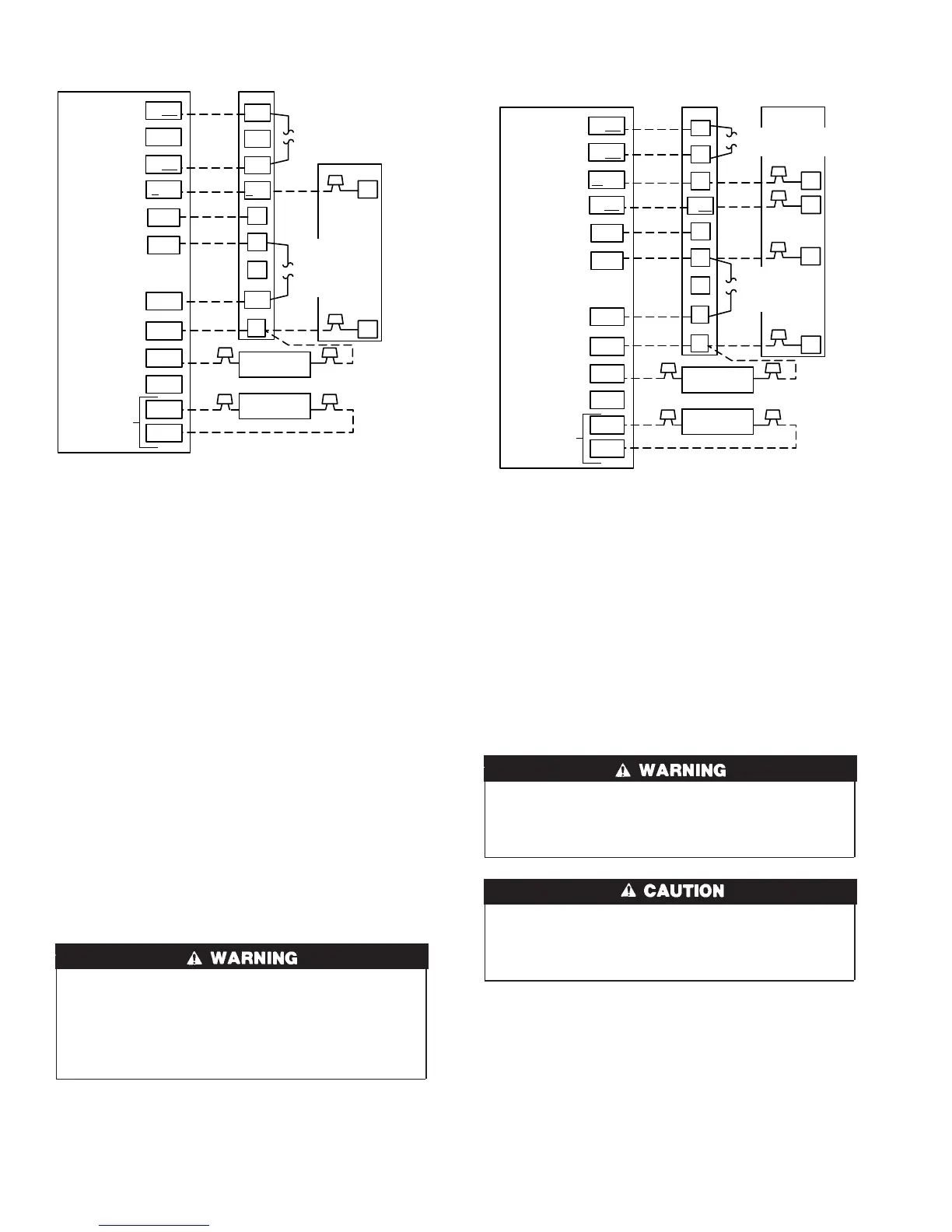

Fig. 8—40FKA Fan Coil with 1-Speed Air Conditioner

A98232

O/W2

Y1/W2

W/W1

G

R

W2

Y1

INDOOR CONTROL

40FKA

FAN COIL

1-SPEED

AIR CONDITIONER

W1

G

C

Y

C

DHUM

HUM

B

S1

S2

Y/Y2

R

O

C

DH

HEAT STAGE 2

N/A

HEAT STAGE 1

COOL STAGE 1

FAN

24 VAC HOT

24 VAC COMM

DEHUMIDIFY

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

Y/Y2

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

REMOVE J2 JUMPER

FOR HEAT STAGING

REMOVE

J1 JUMPER

FOR

DEHUMIDIFY

MODES

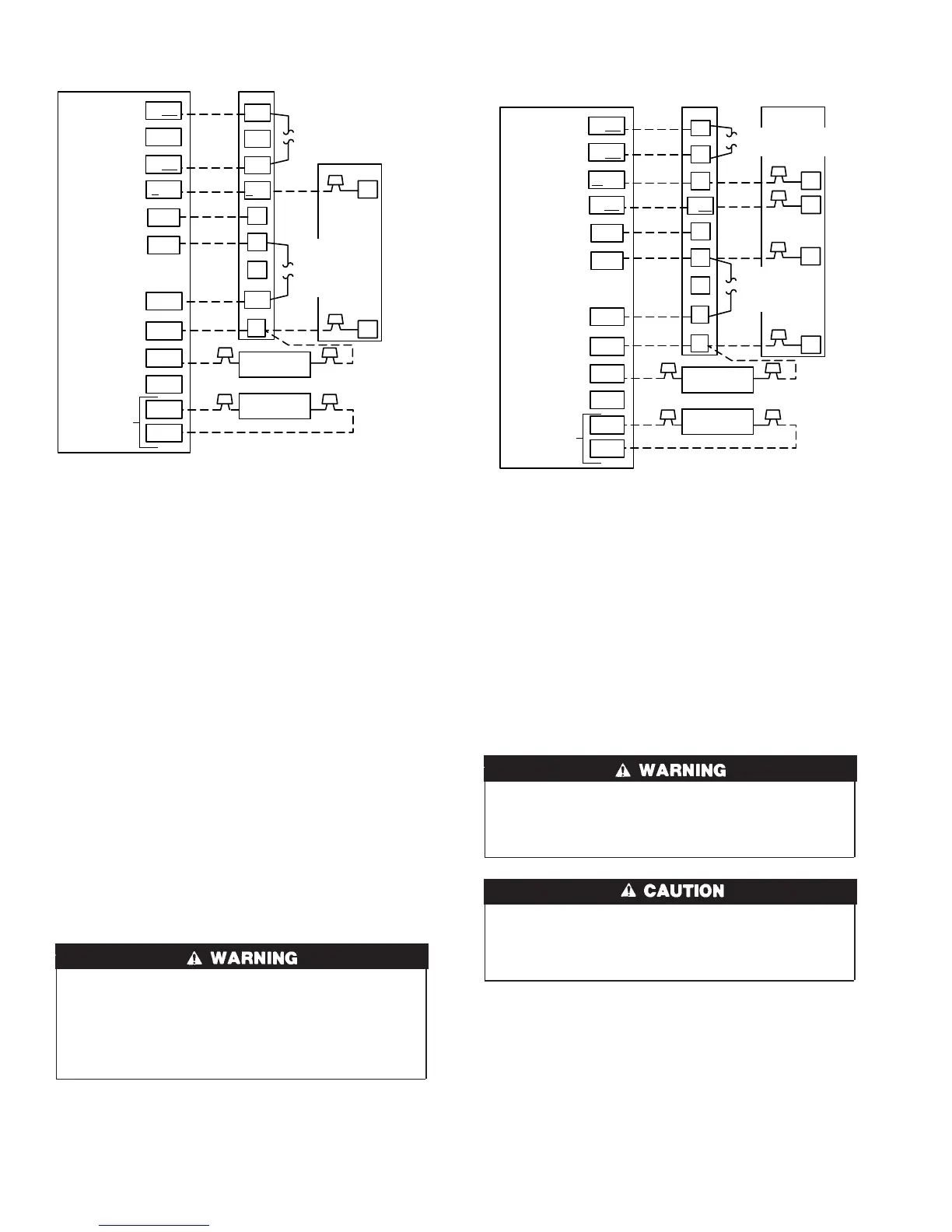

Fig. 9—40FKA Fan Coil with 2-Speed Air Conditioner

A98233

O/W2

W/W1

Y1/W2

G

R

W2

W1

INDOOR CONTROL

40FKA

FAN COIL

2-SPEED

AIR CONDITIONER

Y1

G

C

Y2

R

Y1

C

DHUM

HUM

B

S1

S2

Y/Y2

R

O

C

DH

HEAT STAGE 2

HEAT STAGE 1

COOL STAGE 1

COOL STAGE 2

FAN

24 VAC HOT

24 VAC COMM

DEHUMIDIFY

HUMIDIFY

N/A

OUTDOOR

SENSOR

CONNECTION

Y/Y2

HUMIDIFIER

(24 VAC)

OUTDOOR

SENSOR

REMOVE J2 JUMPER

FOR HEAT STAGING

REMOVE

J1 JUMPER FOR

DEHUMIDIFY

MODES

6

→

Loading...

Loading...